Hengsheng Aluminium Plate-fin Hydraulic Oil Heat Exchanger Road Maintenance Vehicle Radiator Crane Hydraulic Oil Cooler Radiator for Harvester Lubricating Oil Radiator Heat Exchanger for Crusher Air-c

products specifica

| Price | ¥1900-¥2100/$300-$330 |

| Brand | Hengsheng |

| Type | Air-cooled oil cooler |

| Structure | Aluminium plate fin type (Aluminum plate fin type) |

| Model | LQF1-45TZ |

| Processing customisation | Yes |

| Heat transfer mode | Heat conduction, heat convection |

| Applicable models | All kinds of vehicles hydraulic, hydraulic transmission system, lubrication system cooling |

| Temperature control range | 50℃-60℃. |

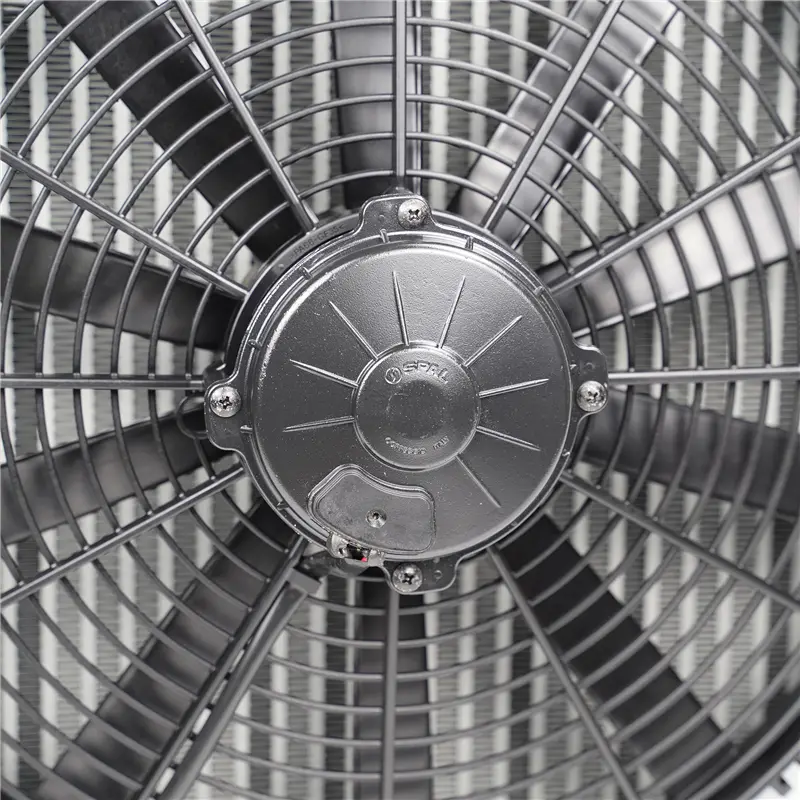

| Fan power supply | DC24V 8.5A (SPAL import fan) |

| Weight | 26.5Kg |

| Heat dissipation area | 19 square metres |

| Working pressure | ≤2.6MPa |

| Available for sale | Nationwide |

about hengsheng

Air-cooled oil coolers

In modern industry, the role of oil coolers cannot be underestimated. As a kind of efficient cooling equipment, air cooled oil cooler is widely used in various machines and equipments to ensure their normal operation in high temperature environment. Air-cooled oil coolers take the heat away from the oil through air flow, thus effectively reducing the oil temperature and prolonging the service life of the equipment.

Product Description

The air cooled oil cooler adopts advanced design concepts combined with highly efficient heat transfer technology, and is capable of providing stable cooling effect under various working conditions. With its compact structure and easy installation, it is suitable for a wide range of industrial applications. The product not only has excellent corrosion resistance and high temperature resistance, but also can achieve high efficiency cooling effect under low energy consumption, to meet the customer's double demand for performance and economy.

about hengsheng

Xinxiang Hengsheng Heat Exchange Equipment Co., Ltd. is a company specialising in the research, development, production and sales of heat exchange equipment. We are committed to providing customers with high quality air cooling oil coolers and related products. With years of industry experience and technology accumulation, our products enjoy a good reputation in the market. With a professional technical team, we are able to provide customised solutions according to customers' specific needs.

Xinxiang Hengsheng Heat Exchanger Equipment Co., Ltd. always adheres to the principle of ‘quality first, customer first’ and is committed to providing customers with the best quality products and services. Our air cooling oil cooler not only occupies a place in the domestic market, but also exported to overseas, won the trust and support of many customers.

In short, by choosing Xinxiang Hengsheng's air cooling oil cooler, you will get efficient and reliable cooling solutions, which will help your equipments to run stably under various working conditions.

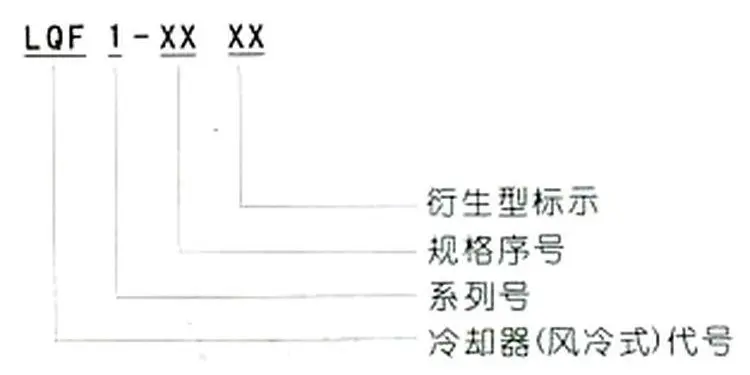

Model Description

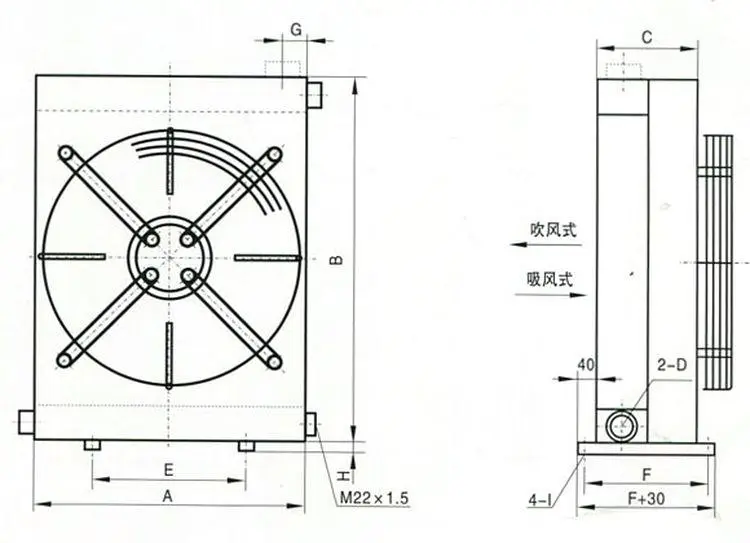

Structure and dimensions

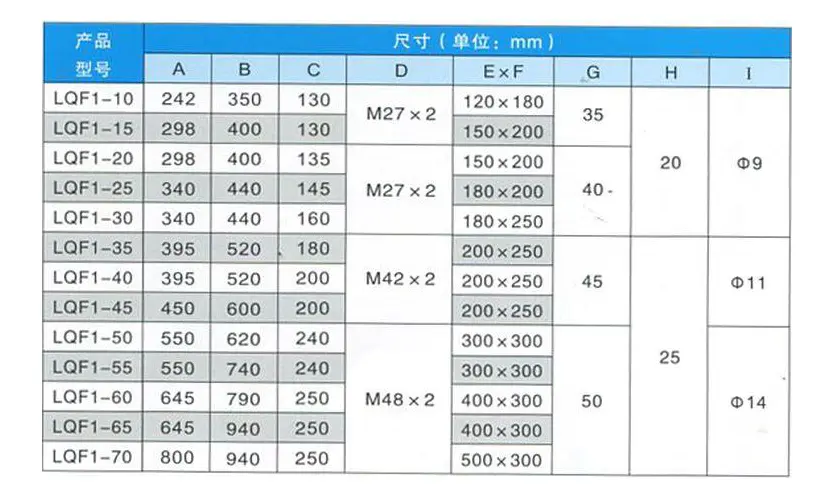

Technical parameters

Quick Selection

Quick selection can be made according to the following instructions:

1. According to the size of the oil flow to choose the cooler oil port form

In principle, the oil flow through the cooler ≤ 300L / Min, as far as possible to choose the threaded port that is the LQF1 series, in order to make the structure simple, fast loading and unloading; when the oil flow > 300L / Min, should be selected flange port that is the LQF2 series, in order to reduce the oil flow through the cooler when the pressure drop.

2. Simple selection calculation

a. Estimate the heating power of the system on the oil to determine the maximum allowable operating temperature of the oil and ambient temperature;

b. According to the principle of heat balance, the use of ‘technical parameters’ table in the formula P = K - ΔT calculated the required K value.

3. Select the specific model

According to the calculated K value and has been selected in the form of oil port, in the appropriate ‘technical parameters’ table to select the closest larger model.

Note: Due to the cooler exposed fins are easy to accumulate dirt, and the accumulation of dirt will significantly reduce the cooling effect of the cooler, therefore, if the cooler is working in the oil and dust in a more serious environment, the selection of models should be left with a larger margin.

Hints and suggestions

1. On the use of blowing or suction type fan and cooler installation location, should be mainly considered to prevent the cooler has been heated by other components of the hot air inhalation, to prevent the hot air from the cooler discharged from the normal work of the equipment and personnel as well as to ensure that the air into the air and the exhaust air free and smooth.

2. Use should avoid sudden changes in flow and pressure impact to ensure that the maximum allowable static working pressure is not exceeded. In order to ensure the safety of the work of the cooler, we recommend that the user, and the cooler in parallel with a bypass valve (check valve) directly to the tank.

3. For the system working under non-continuous design load, in order to facilitate the control of oil temperature in a reasonable range, we recommend the installation of a temperature control switch to control the fan's rotation.

4. Due to the diversity of the working system and the complexity of the installation environment, we recommend that the user in the system design stage can consult our technical department, we would like to provide more information for your reference.

detail pictures