In the competitive automotive industry, maintaining effective Radiator Quality Control is vital for enhancing performance. According to a recent report by the Automotive Engineering Society, nearly 30% of radiator failures result from inadequate quality checks during production. This alarming statistic highlights a crucial need for improved quality management strategies.

Industry expert Dr. Emily Harper emphasizes the importance of rigorous testing, stating, "Quality control is not just a process; it's the backbone of reliable performance." Companies must focus on implementing advanced inspection techniques and regular maintenance schedules. The reality is that many manufacturers overlook these aspects, leading to expensive recalls and dissatisfied customers.

Moreover, the evolving technology in radiator manufacturing presents both challenges and opportunities. While new materials offer enhanced durability, they also require more precise quality control processes. A failure to adapt can result in significant performance issues. Companies must reflect on their current practices and make necessary adjustments to ensure they meet the highest standards in Radiator Quality Control.

When considering radiator quality control, several key aspects must be taken into account. One crucial area is material selection. It's essential to choose high-quality materials that can withstand extreme temperatures without degrading. Poor choices here can lead to leaks and inefficiency. This is not always straightforward. Sometimes, cheaper options seem appealing, yet their long-term consequences can be costly.

Another significant aspect is the manufacturing process. Consistency in production is vital. Inadequate quality checks can result in variances that affect performance. Regular inspections during production can help catch defects early. Implementing automated systems for measuring specific parameters can increase reliability. However, these systems are not infallible and require human oversight to function optimally.

Tip: Regular maintenance checks can help identify early signs of wear in radiators. Cleaning and flushing out debris annually ensures efficiency. Small steps prevent larger problems down the line. Keep in mind that neglecting routine checks can lead to costly repairs or replacements. Each detail matters in ensuring the radiator performs at its best.

The quality of materials and components significantly affects radiator performance. High-performance radiators often utilize copper and aluminum. According to industry reports, copper has a thermal conductivity of around 400 W/mK. This allows for efficient heat transfer. Aluminum, while less conductive (about 205 W/mK), is lightweight and resistant to corrosion.

Another critical aspect is the design of the radiator core. A study from the Society of Automotive Engineers highlights that fin design can enhance airflow and cooling efficiency by up to 30%. Using optimized fin patterns can also reduce material costs, yet many designs still struggle to reach this potential.

Sealing and bonding techniques play a vital role too. Poor welds can lead to leaks, undermining performance. Material choices for seals, such as silicone or rubber, can greatly influence durability. Reports indicate that using high-quality seals can prevent 15-20% of common failures. However, some manufacturers cut corners, leading to increased maintenance costs. Investing in quality materials is essential for long-term reliability.

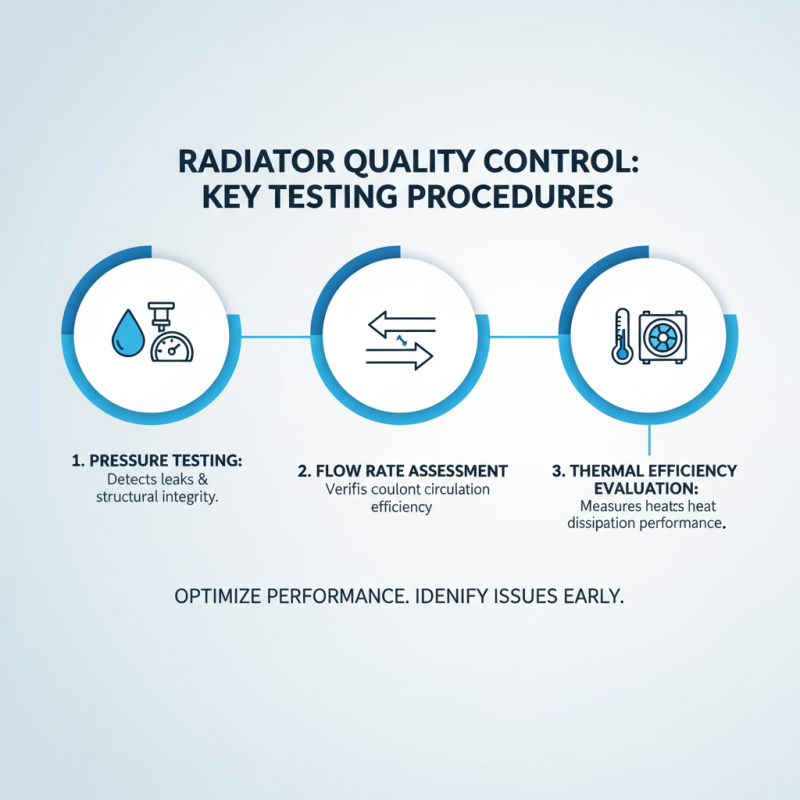

Effective testing procedures are crucial for radiator quality control. They ensure performance is optimized and potential issues are identified early. Key testing procedures include pressure testing, flow rate assessment, and thermal efficiency evaluation. Each method reveals insights into radiator functionality.

Tip: Conduct pressure tests regularly. This measures the integrity of the radiator. A small leak can lead to major performance issues later. Check connections thoroughly.

Another important aspect is flow rate assessment. Ensuring that coolant flows efficiently through the radiator is vital. Blockages can reduce performance. Have a routine schedule for cleaning and inspecting flow channels.

Lastly, thermal efficiency evaluation helps confirm that the radiator dissipates heat properly. Use infrared thermometers for accurate readings. If the surface temperature is uneven, it could indicate underlying issues. These testing procedures are not foolproof. Continuous improvement in methods is needed.

Radiators are essential for a vehicle's cooling system. However, they often face common defects that can impact performance. Identifying these issues early on can save time and money. You may notice visible leaks. A puddle under your car can indicate a serious problem. If you see steam, that’s a red flag too. These defects usually emerge from corrosion or damage to the radiator.

Another common issue is overheating. If your engine temperature rises above normal, the radiator might not be functioning correctly. You could experience inconsistent heating inside the car. A faulty thermostat is often the culprit here. Sometimes you may find unusual noises. High-pitched sounds or hissing can suggest air trapped in the system. Ignoring these issues can lead to costly repairs later.

Look out for discolored coolant. A rusty color can indicate corrosion within the radiator. Check for physical damage. Dents or bent fins can severely reduce efficiency. Simple inspections can go a long way. Regularly cleaning and maintaining your radiator can help avoid these defects. However, remember that even the most diligent efforts may not catch every problem. Always keep an eye on performance and be prepared to troubleshoot.

| Common Defects | Identification Method | Impact on Performance | Preventive Measures |

|---|---|---|---|

| Leaking Radiator | Visual inspection for fluid stains or puddles beneath the radiator. | Reduced coolant efficiency and overheating risks. | Regular checks and immediate repairs of any cracks or corrosion. |

| Clogged Radiator | Check for unequal temperature distribution across the radiator surface. | Overheating engine and reduced cooling efficiency. | Regular flushing of the coolant system and using quality fluids. |

| Corrosion | Look for rust spots or discoloration on the radiator exterior. | Perforation leading to leaks and coolant loss. | Use corrosion inhibitors and ensure proper cooling system maintenance. |

| Poor Heat Transfer | Monitor engine temperature and check if the radiator is hot to the touch. | Engine overheating and reduced performance. | Ensure adequate airflow and clean external surfaces regularly. |

| Fittings or Hose Issues | Inspect hoses for cracks, rigidity, or leaks at connections. | Coolant loss and potential engine damage. | Regular inspection and replacement of worn hoses and fittings. |

In radiator production, ongoing quality improvement is essential. Consistent monitoring of raw materials is vital. Each component must meet set standards to ensure optimal performance. A minor defect can lead to significant issues later on. Regular checks can prevent costly recalls. Therefore, it’s beneficial to develop a systematic approach in material selection.

Another practice involves employee training. Workers need to stay updated on the latest techniques. This ensures better handling of equipment. When operators know how to manage machines efficiently, the production line runs smoother. However, training sessions can be irregular. Many workers admit they feel unprepared at times. Addressing these gaps is crucial for maintaining standards.

Quality audits should be regular. They reveal hidden problems that need attention. Relying on end-of-line inspections alone is risky. Many defects slip through unnoticed. Establishing a culture of continuous improvement is necessary. Employees should feel encouraged to report issues. They can propose ideas that lead to better processes. This engagement can drive real change in production quality.