In the quest for improved operational efficiency, optimizing your compressors cooler is a critical step that can yield substantial benefits for your system's performance. A well-functioning compressors cooler not only enhances the cooling process but also contributes to energy savings and prolonged equipment life.

By focusing on various aspects such as proper maintenance, design modifications, and employing advanced cooling techniques, you can unlock the full potential of your cooling system. In this guide, we will explore actionable strategies that will enable you to fine-tune your compressors cooler, ensuring that it operates at peak efficiency.

From understanding the principles of heat exchange to implementing the latest technological advancements, these insights will help you achieve optimal performance, reduce downtime, and ultimately lower operational costs. Whether you're a seasoned engineer or a facility manager, maximizing the efficiency of your compressors cooler is an essential facet of maintaining a competitive edge in today's demanding industrial landscape.

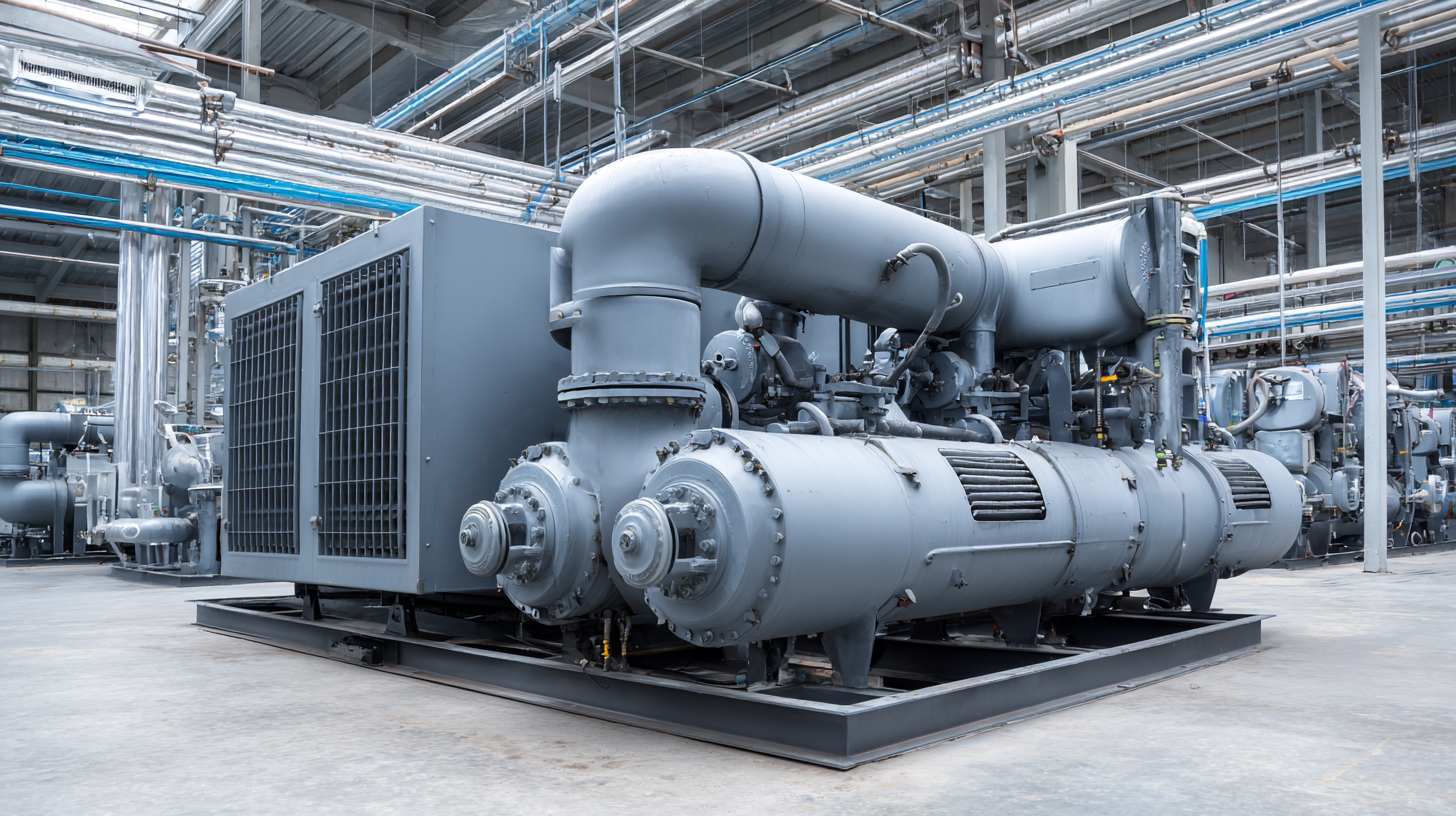

Compressor coolers play a critical role in maintaining the efficiency and longevity of compressors in various industrial applications. These cooling systems help regulate the operating temperature of compressors, thereby preventing overheating, which can lead to significant operational failures. According to a report by the Department of Energy, improper cooling can reduce compressor efficiency by up to 30%, emphasizing the necessity of optimizing cooling systems for better performance and energy savings.

Understanding the basics of compressor coolers reveals key considerations for maintenance and performance enhancement. Effective coolers typically utilize either air or liquid cooling methods. For example, liquid-cooled systems can achieve lower temperatures compared to their air-cooled counterparts, thereby improving overall thermal efficiency. The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) indicates that optimizing these systems can extend equipment lifespan by as much as 50% and significantly decrease maintenance costs. By prioritizing cooler efficiency, companies can not only boost productivity but also contribute to overall energy conservation efforts in their operations.

When optimizing the efficiency of a compressor's cooler, it is essential to identify the key factors that influence its performance. One primary factor is the design of the cooler itself. Coolers with larger surface areas enable better heat transfer, allowing for more effective cooling of the compressor's discharge air. Additionally, the choice of materials plays a crucial role; materials with high thermal conductivity facilitate quicker heat dissipation, improving overall efficiency.

Another critical element affecting cooler efficiency is airflow. Proper airflow around the cooler ensures that hot air is efficiently expelled and fresh, cooler air is drawn in, preventing overheating. This can be achieved by positioning the cooler in a location with adequate space for airflow, as well as using fans or blowers to enhance circulation. Furthermore, regular maintenance, such as cleaning the cooler surfaces and checking for blockages, is vital to maintain optimal airflow and cooling capacity, helping to sustain the performance of the entire compressor system.

Implementing regular maintenance practices is crucial for the optimal performance of compressors. A study by the Compressed Air and Gas Institute (CAGI) highlights that companies can save up to 30% on energy costs by ensuring clean and well-maintained cooling systems. This not only enhances efficiency but also extends the lifespan of the compressor equipment. Regular checks on coolant levels, cleaning filters, and monitoring the functionality of fans can prevent overheating and inefficiencies that lead to costly downtime.

**Tip:** Schedule monthly inspections to clean coils and check fluid levels. This simple routine can significantly boost your compressor's performance and energy efficiency.

Furthermore, incorporating predictive maintenance techniques can be a game-changer. According to research by the International Journal of Energy Research, predictive maintenance can reduce operational costs by as much as 12%. By using temperature and vibration monitoring tools, operators can detect early signs of wear or malfunction before they escalate into major issues.

**Tip:** Invest in sensor technologies that provide real-time data about the compressor's operational health to preemptively address potential failures.

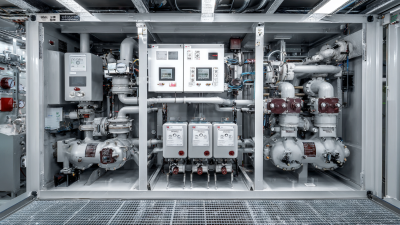

When selecting the right cooler type for your compressor needs, it’s essential to consider various factors that affect efficiency and performance. Air-cooled and water-cooled options are the most common types, each with distinct advantages. Air-cooled coolers are generally more straightforward in installation and maintenance, making them ideal for mobile or temporary setups. They operate well in environments with easy airflow but may struggle in hotter conditions, reducing their overall effectiveness.

On the other hand, water-cooled coolers provide superior heat dissipation and are often more efficient in high-demand scenarios. They are excellent for industrial settings where water access is readily available, allowing for consistent cooling even during extended operation periods. When choosing the right type, assess your specific application requirements, including ambient conditions, space limitations, and cooling capacity needs, to ensure optimal performance and longevity of your compressor system.

Optimizing your compressor’s cooler for maximum efficiency hinges significantly on improving airflow and mastering temperature management techniques. According to a report by the Compressed Air and Gas Institute, effective cooling systems can enhance compressor efficiency by up to 15%, directly translating to reduced energy costs and lower operational risks. Ensuring that the cooler has unobstructed airflow is crucial; utilizing larger inlet and outlet ducts can help minimize pressure drop and enable optimal air circulation.

Temperature management is equally essential, as excess heat can lead to higher operational costs and potential equipment failure. A study by the U.S. Department of Energy highlights that maintaining an optimal cooling temperature can improve the lifespan of compressor components by around 20%. Techniques such as regular maintenance of cooling fins and the use of thermal insulation can aid in dissipating heat more effectively. Additionally, implementing advanced cooling technologies, like variable speed fans, can adapt to varying operational demands, thereby achieving a more precise temperature control and further enhancing overall efficiency.