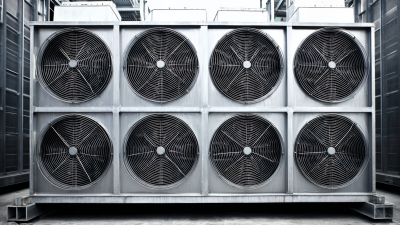

As the global automotive and industrial sectors increasingly prioritize energy efficiency and thermal management, innovations in oil cooler technology are becoming essential. The 138th Canton Fair in 2025 serves as an ideal platform to explore emerging trends and advancements in this critical component of machinery. According to a recent industry report by Mordor Intelligence, the oil cooler market is projected to grow at a CAGR of 5.6% by 2026, driven by heightened demand for more efficient cooling systems in various applications, including automotive, aerospace, and industrial machinery. With innovations such as lightweight materials and enhanced heat exchange mechanisms, manufacturers are poised to revolutionize oil cooler designs. The Fair promises to feature cutting-edge solutions that not only optimize performance but also contribute to sustainability goals. Engaging with industry leaders and innovative startups at this event will provide insights into future directions for oil cooler innovations, making it a pivotal gathering for stakeholders in the thermal management space.

As the global automotive and industrial sectors increasingly prioritize energy efficiency and thermal management, innovations in oil cooler technology are becoming essential. The 138th Canton Fair in 2025 serves as an ideal platform to explore emerging trends and advancements in this critical component of machinery. According to a recent industry report by Mordor Intelligence, the oil cooler market is projected to grow at a CAGR of 5.6% by 2026, driven by heightened demand for more efficient cooling systems in various applications, including automotive, aerospace, and industrial machinery. With innovations such as lightweight materials and enhanced heat exchange mechanisms, manufacturers are poised to revolutionize oil cooler designs. The Fair promises to feature cutting-edge solutions that not only optimize performance but also contribute to sustainability goals. Engaging with industry leaders and innovative startups at this event will provide insights into future directions for oil cooler innovations, making it a pivotal gathering for stakeholders in the thermal management space.

The 138th Canton Fair in 2025 presents a pivotal platform for showcasing innovative trends in oil cooler technologies. As industries increasingly pivot towards sustainable practices, oil cooler manufacturers are tasked with developing solutions that enhance energy efficiency and reduce environmental impact. According to a recent market analysis, the global oil cooler market is projected to grow at a CAGR of 5.8% from 2023 to 2030, highlighting the rising demand for advanced cooling solutions across diverse sectors, including automotive and industrial applications.

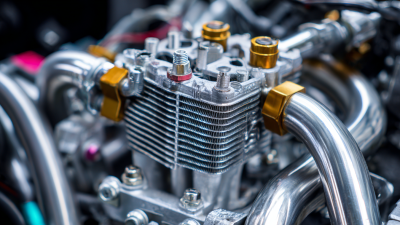

Among the exhibitors, companies are set to introduce cutting-edge designs that leverage smart technology and improved materials. The adoption of lightweight, high-performance composites is one trend gaining traction, as these materials promise to enhance heat dissipation while reducing the overall weight of the oil coolers. Additionally, the integration of IoT technology into oil cooler systems allows for real-time monitoring and optimization, greatly improving operational efficiency. With such innovations on the horizon, the 138th Canton Fair will undoubtedly illuminate the future pathways for oil cooler advancements, fostering collaboration and knowledge sharing among industry leaders.

The forthcoming 138th Canton Fair in 2025 presents an extraordinary platform for showcasing innovations in oil cooler technology, particularly in response to the evolving market demand for automotive and industrial applications. As vehicles and machinery become more sophisticated, the need for efficient thermal management systems, such as oil coolers, is paramount. This demand is driven by stricter emissions regulations and the continuous quest for improved fuel efficiency, which has led manufacturers to rethink conventional designs and explore advanced materials and engineering solutions.

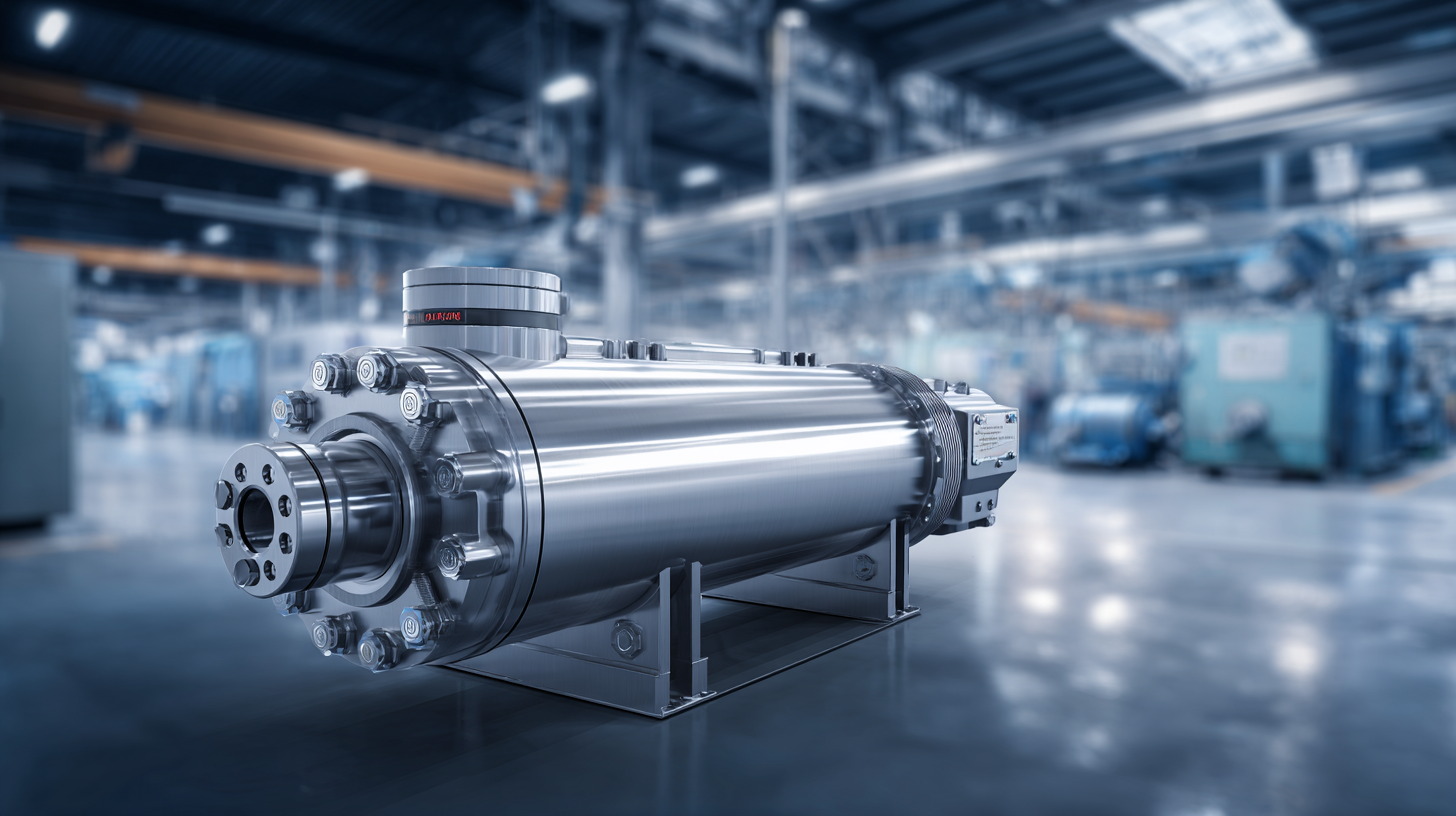

In the automotive sector, the integration of oil coolers is crucial for enhancing engine performance and longevity. With the rise of electric vehicles and hybrid technologies, the application of oil coolers extends beyond traditional combustion engines, presenting new opportunities for innovation. Similarly, industries reliant on hydraulic systems require robust oil cooling solutions to maintain operational efficiency under high-stress conditions.

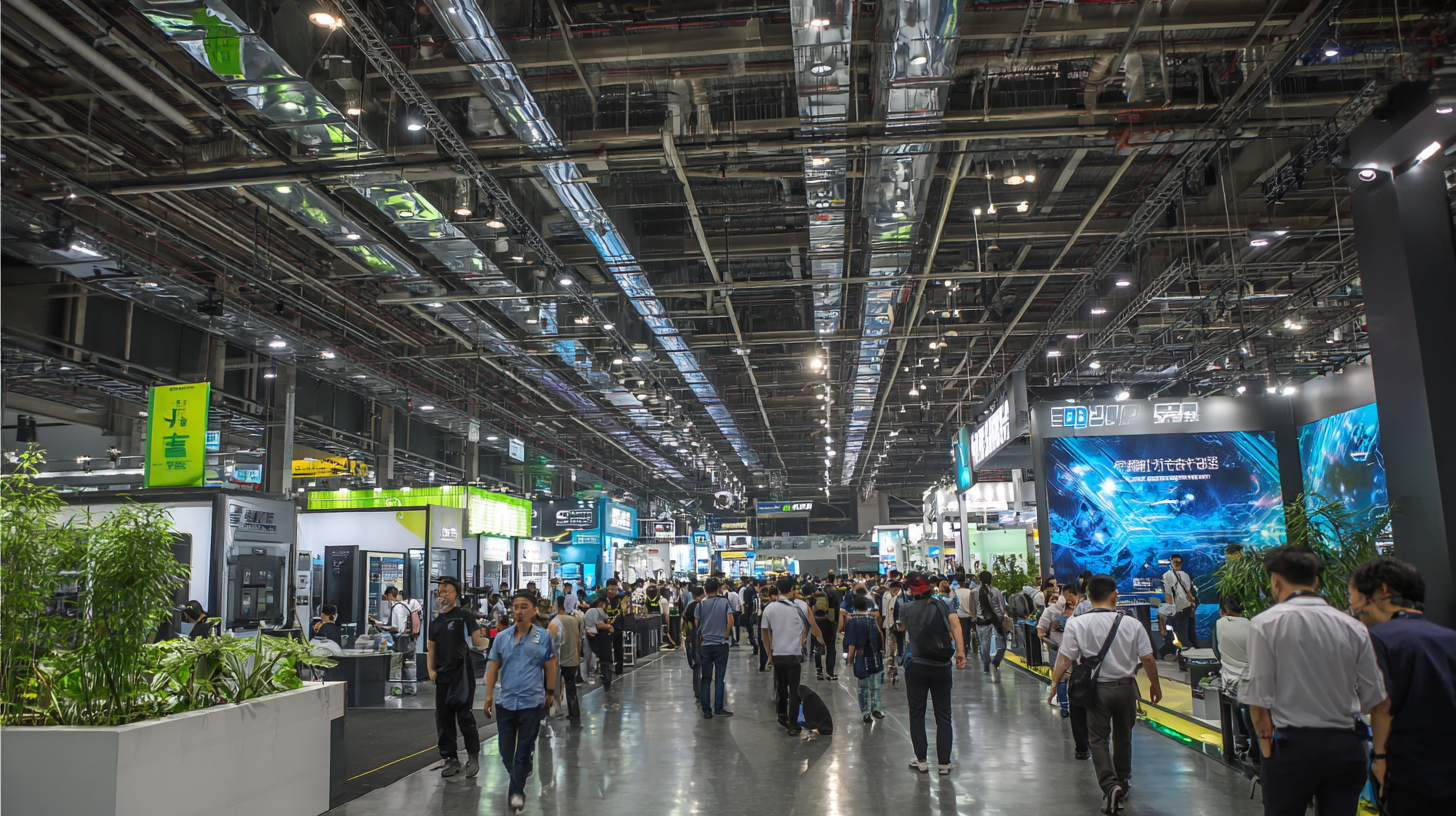

The Canton Fair will be an ideal venue for manufacturers and innovators to present their cutting-edge products, explore collaborations, and respond to the pressing market needs, ultimately shaping the future landscape of oil cooling technologies.

Sustainable design practices in oil cooler manufacturing are gaining traction as industries increasingly prioritize environmental responsibility. With the rise of generative AI and its considerable energy demands, manufacturers in this sector are prompted to seek cleaner energy solutions and optimize their production processes. Innovations such as biobased materials and advanced prefabrication techniques now assume a central role in reducing the carbon footprint of oil cooler products. This shift not only aligns with global sustainability trends but also enhances efficiency in energy consumption during manufacturing.

Tips: To foster sustainable practices, manufacturers should invest in research focused on eco-friendly materials for their products. Collaboration with technology firms can also lead to the development of innovative solutions that incorporate energy-efficient designs and contribute to a greener future.

As the 138th Canton Fair draws near, showcasing innovations in oil cooler design will highlight commitments to sustainability in manufacturing practices. These advancements resonate within a broader industrial context where sectors, such as semiconductor manufacturing, are increasingly recognizing the necessity of sustainable methods. By focusing on the dual challenge of maintaining performance while implementing greener practices, the oil cooler industry sets a precedent for future developments.

Tips: Companies should engage in continuous education about sustainable practices and incentivize their teams to pursue innovative ideas that align with environmental goals. Networking at industry events can also lead to valuable collaborations that drive the sustainability agenda forward.

As the oil cooler industry continues to evolve, insights from emerging competitors reveal significant opportunities for innovation. Industry leaders are increasingly focused on energy-efficient solutions in response to the rising demand for sustainable technology. The burgeoning need for reliability and performance in oil coolers mirrors trends seen in the data center sector, which is aggressively pursuing energy efficiency and smarter designs to support the growth of generative AI.

Furthermore, the integration of Industry 4.0 technologies presents an exciting avenue for oil cooler manufacturers. By leveraging advancements in artificial intelligence and the Internet of Things, companies can enhance their product offerings while addressing the growing concerns around energy consumption and environmental impact. The collaborative spirit within the industry and a commitment to sustainability are likely to be significant differentiators for emerging competitors in the oil cooler market as they strive to lead in innovation at events like the Canton Fair.

The upcoming 138th Canton Fair in 2025 presents a prime opportunity to delve into the latest technological advancements in oil cooler design. Innovations in materials and manufacturing processes are significantly enhancing the performance and efficiency of oil coolers, making it easier for industries to meet stringent regulations and improve operational reliability. Features such as improved airflow dynamics and optimized heat exchange surfaces are becoming critical in maximizing cooling efficiency.

**Tips for Attendees:** When exploring oil cooler technologies, look for exhibitors showcasing eco-friendly materials and energy-efficient designs. Ask about the latest computational fluid dynamics (CFD) simulations used in developing these products, as they can provide insights into performance metrics.

Moreover, advancements in smart technologies are being integrated into oil cooler systems. These include IoT devices that monitor coolant temperatures and system pressures, allowing for real-time data analysis and predictive maintenance. This shift not only enhances the longevity of the oil coolers but also provides companies with actionable insights to optimize their operations.

**Tips for Networking:** Engage with manufacturers about their unique selling propositions concerning efficiency enhancements. Sharing best practices and case studies can lead to fruitful collaborations and innovations tailored to specific industry needs.

| Innovation Type | Technology Used | Performance Increase (%) | Efficiency Metric | Application Sector |

|---|---|---|---|---|

| Phase Change Material | PCM Technology | 25% | Thermal Conductivity | Automotive |

| Nano-coating | Nanotechnology | 15% | Heat Dissipation Rate | Industrial Machinery |

| Enhanced Fluid Dynamics | CFD Analysis | 30% | Pressure Drop | Aerospace |

| Smart Oil Coolers | IoT Integration | 20% | Temperature Control | Energy Systems |

| Modular Design | 3D Printing | 10% | Cooling Efficiency | HVAC |