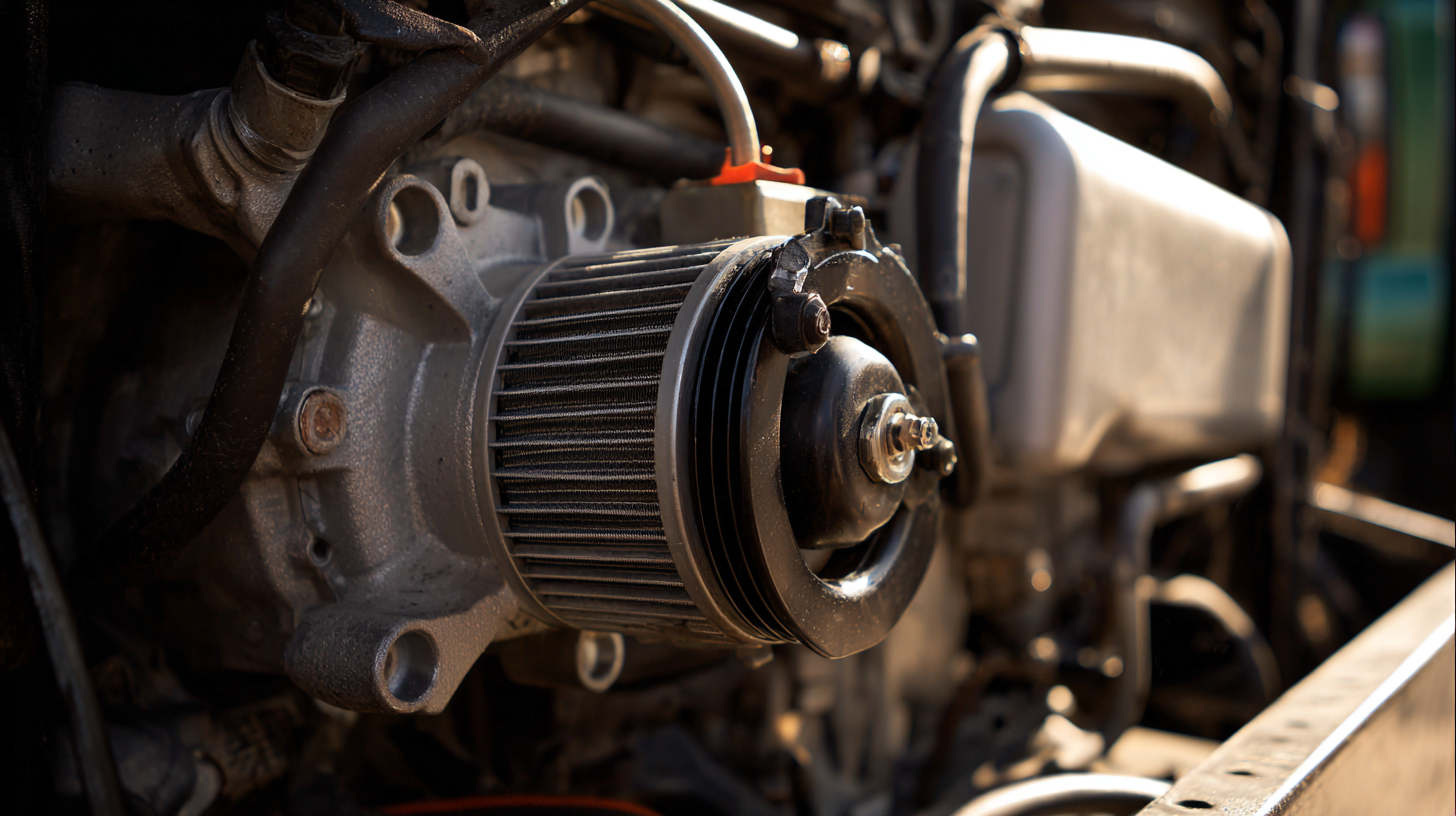

In the pursuit of maximizing vehicle longevity, understanding the critical role of the Transmission Oil Cooler becomes essential for every car owner. This vital component serves as a key player in preventing overheating, which can lead to costly repairs and diminished performance. As vehicles become more advanced, the demand for efficient cooling systems has never been higher, making it essential to recognize how a Transmission Oil Cooler contributes to maintaining optimal operating temperatures. By effectively managing heat generated during transmission operation, these coolers not only enhance the overall performance of the vehicle but also significantly extend its lifespan. This article will explore the best practices for utilizing Transmission Oil Coolers, shedding light on their impact on vehicle maintenance and performance, ensuring that you get the most out of your automobile investment.

Properly maintaining the transmission is crucial for enhancing vehicle performance and longevity, and one key component in this maintenance is the transmission oil cooler. According to the American Transmission Repair Association, overheating is a leading cause of transmission failure, accounting for approximately 90% of all transmission issues. Transmission oil coolers play a vital role in regulating oil temperatures, ensuring that the transmission fluid remains at optimal levels to facilitate smooth operation and reduce wear and tear.

In fact, a study by J.D. Power highlights that vehicles equipped with dedicated oil coolers experience significantly less overheating-related maintenance issues, with a reported decrease in repair costs by up to 30%. By preventing the transmission fluid from reaching excessive temperatures, oil coolers preserve the integrity and longevity of transmission components, ultimately contributing to improved vehicle reliability and performance. As vehicle technology advances, understanding the importance of transmission oil coolers becomes essential for both manufacturers and consumers looking to maximize their investment and ensure their vehicles run smoothly for years to come.

Transmission overheating is a significant concern for vehicle owners, as it can lead to costly repairs and reduced vehicle lifespan. When the transmission oil temperature rises beyond its optimal range, it can break down the lubricant's protective properties, resulting in increased friction and wear on internal components. This overheating can be triggered by various factors, including heavy towing, driving in extreme conditions, or even insufficient fluid levels. Understanding these mechanics is crucial for maintaining the health of the vehicle's transmission system.

The role of transmission oil coolers becomes pivotal in preventing overheating. These coolers work by dissipating excess heat generated during the transmission's operation, ensuring that the fluid maintains a stable temperature. By regularly monitoring and maintaining the transmission fluid and cooler system, drivers can enhance their vehicle's performance and longevity. Additionally, recognizing the signs of a failing transmission cooler, such as slipping gears or unusual noises, allows for timely intervention before severe damage occurs. Proper care and understanding of transmission mechanics can ultimately save owners from extensive repairs and improve overall driving experience.

| Transmission Type | Recommended Cooler Type | Optimal Operating Temperature (°F) | Common Overheating Symptoms | Maintenance Frequency (Miles) |

|---|---|---|---|---|

| Automatic | Plate-type Cooler | 175-220 | Slipping, Delayed Engagement | 30,000 |

| Manual | Air-to-Oil Cooler | 165-195 | Difficulty Shifting, Unusual Noises | 20,000 |

| CVT (Continuously Variable Transmission) | Belt-driven Cooler | 180-210 | Shuddering, Over Revving | 15,000 |

| DCT (Dual Clutch Transmission) | Integrated Cooler | 170-200 | Failed Shifts, Warning Light | 25,000 |

Transmission fluid temperature plays a critical role in the overall health of a vehicle's transmission system. According to the Automotive Service Association, optimal operating temperature for transmission fluid is typically between 175°F and 220°F (80°C to 105°C). Exceeding this range can lead to significant wear and tear on transmission components, ultimately resulting in costly repairs. As vehicles age and accumulate mileage, the efficiency of the transmission fluid cooler can diminish, making it essential for drivers to monitor fluid temperatures closely.

Transmission fluid temperature plays a critical role in the overall health of a vehicle's transmission system. According to the Automotive Service Association, optimal operating temperature for transmission fluid is typically between 175°F and 220°F (80°C to 105°C). Exceeding this range can lead to significant wear and tear on transmission components, ultimately resulting in costly repairs. As vehicles age and accumulate mileage, the efficiency of the transmission fluid cooler can diminish, making it essential for drivers to monitor fluid temperatures closely.

Key indicators that may suggest overheating include erratic shifting, slipping gears, or an illuminated check engine light. Industry data indicates that around 74% of transmission failures are related to overheating issues, with improperly maintained fluid being a major contributor. Regularly checking transmission fluid levels and quality, as well as inspecting the cooler for obstructions, can significantly extend the life of a transmission. By staying vigilant about these indicators, vehicle owners can prevent serious damage and costly repairs, maintaining both performance and longevity of their vehicles.

Maintaining transmission oil coolers is crucial for ensuring the optimal performance and longevity of vehicles. According to the Society of Automotive Engineers (SAE), nearly 70% of automatic transmission failures are attributed to overheating. This statistic underscores the importance of effective cooling systems in preventing such issues. Regular maintenance of transmission oil coolers not only enhances the efficiency of the vehicle but also extends the lifespan of the transmission itself.

Tips: Inspect your transmission oil cooler at least once a year for any signs of leaks or corrosion. Keeping the cooler clean and free from debris allows for effective heat exchange and prevents overheating. Additionally, using high-quality transmission fluid, as recommended by the manufacturer, can drastically improve the cooler's performance and the overall transmission efficiency.

Properly maintaining your transmission oil cooler involves checking the hoses and connections for wear and tear, as these components play a vital role in fluid circulation. The National Institute for Automotive Service Excellence (ASE) suggests that flushing the transmission fluid every 30,000 miles can help avoid build-up and ensure the cooler operates efficiently. Regular maintenance checks and timely replacement of worn-out parts can save vehicle owners from costly repairs down the line.

In the quest for vehicle longevity, the importance of transmission oil coolers cannot be overstated. These critical components play a vital role in managing the temperature of the transmission fluid, which is essential for optimal performance and durability. As vehicles become more sophisticated, industry standards for transmission coolers are evolving, leading to innovations that enhance their efficiency and effectiveness. This makes it imperative for manufacturers to stay updated with the latest technological advancements and incorporate them into their designs.

China, with its burgeoning innovation capabilities, is increasingly becoming a key player in the development of advanced automotive technologies, including transmission oil coolers. Leveraging research from universities and collaborations with domestic companies, the country is on the forefront of creating cutting-edge solutions that improve vehicle performance and longevity. This emphasis on innovation not only elevates industry standards but also sets a precedent for other regions to follow, ultimately benefiting consumers with more reliable and longer-lasting vehicles.