Heat exchangers play a crucial role in a variety of industrial applications, from power plants to refrigeration systems, where efficient thermal transfer is key to operational success. Maximizing the efficiency of your heat exchanger not only enhances performance but also yields significant energy savings, which can lead to considerable reductions in operational costs. In this blog, we will explore five essential tips that can help you optimize the functionality of your heat exchangers. Whether you're involved in maintenance, design, or operation, these best practices are aimed at increasing heat transfer rates, minimizing fouling, and ultimately extending the lifespan of your equipment. By implementing these strategies, you’ll be well on your way to achieving peak efficiency and reliability in your thermal management systems.

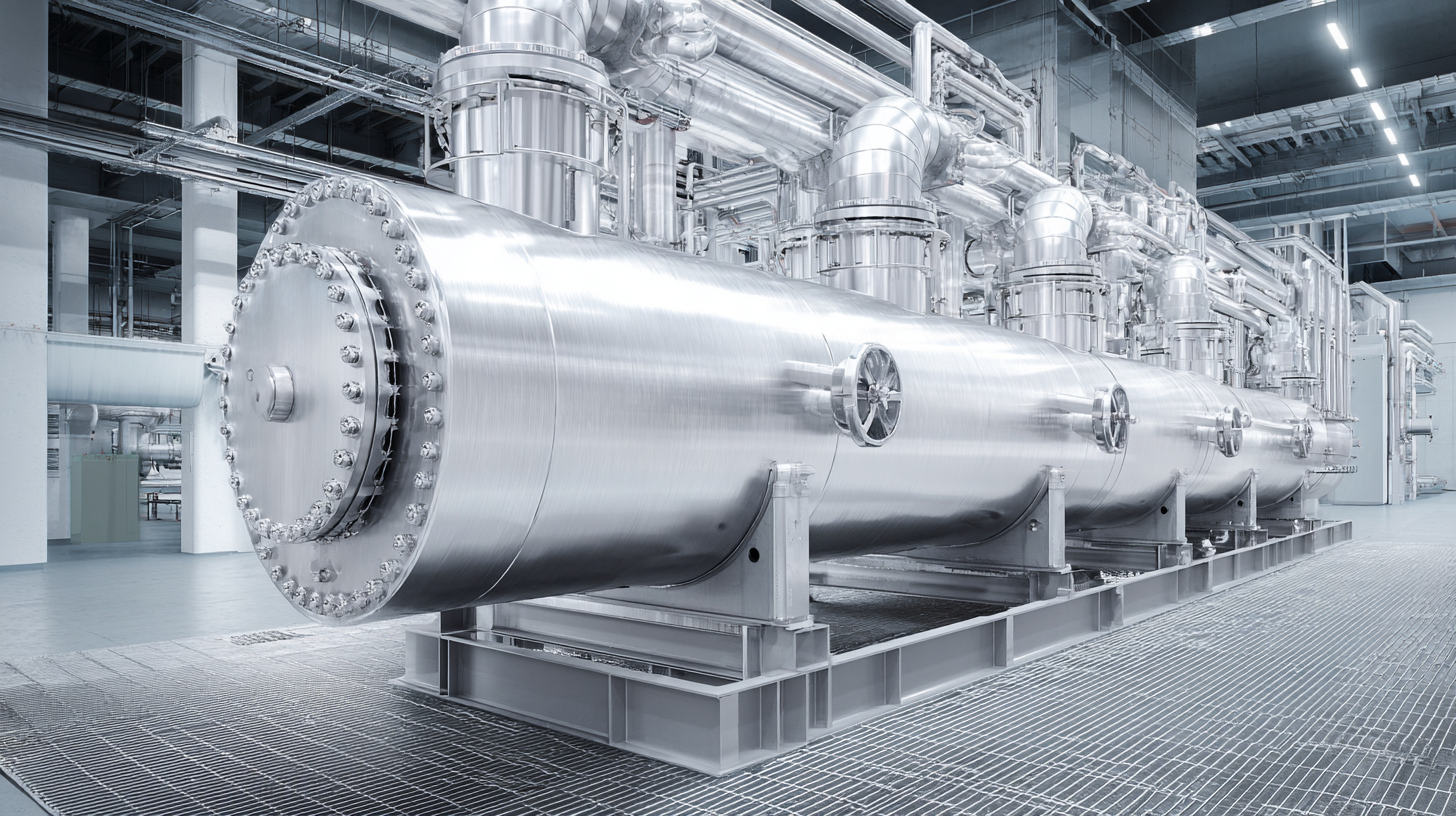

Heat exchangers play a pivotal role in industrial processes, significantly impacting energy efficiency and operational costs. Understanding the various types of heat exchangers—such as shell-and-tube, plate, and air-cooled variants—is essential for optimizing performance. According to a report from the International Energy Agency, improving heat exchanger efficiency can lead to energy savings of up to 20% in many applications. This underscores the importance of selecting the right type tailored to the specific needs of your system.

To maximize the efficiency of your heat exchanger, begin by ensuring regular maintenance. Over time, fouling can decrease effectiveness by as much as 40%, leading to increased energy consumption. Implementing a cleaning schedule not only enhances performance but also extends the lifespan of the equipment. Another effective tip is to monitor temperature and pressure drop across the heat exchanger. Staying within recommended parameters ensures optimal heat transfer, as deviations can indicate system inefficiencies.

Employing advanced monitoring technologies can also provide valuable insights into performance metrics. For instance, predictive analytics can identify potential failures before they occur, allowing for timely interventions and reducing unexpected downtime. Utilizing these strategies will elevate your operations and contribute to sustainable practices in energy consumption.

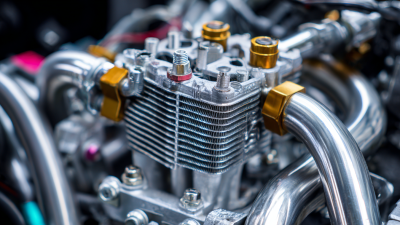

Maximizing the efficiency of heat exchangers is crucial in various industries, particularly in sectors like automotive and energy, where thermal management plays a pivotal role. Key factors impacting heat exchanger performance include fluid dynamics, material selection, and operational conditions. Recent reports indicate that the global superalloy market is expected to grow from $7.82 billion in 2025 to $17.75 billion by 2032, with a compound annual growth rate (CAGR) of 12.4%. This significant growth emphasizes the increasing demand for high-performance materials in heat exchangers, particularly within aerospace and energy applications.

In the automotive realm, as highlighted in the comprehensive studies on commercial vehicle thermal systems, effective heat management is essential to ensure engine efficiency and reliability. The market for commercial vehicle automotive thermal systems is being shaped by advancements in thermal management, expected to witness remarkable growth influenced by rising safety standards and environmental regulations. Adoption of innovative solutions, such as liquid cooling systems, is becoming a necessity rather than a choice, particularly as thermal limits of traditional cooling methods approach their peak. These developments not only enhance the performance of heat exchangers but also contribute to overall system efficiency and sustainability.

Regular maintenance practices are vital for ensuring optimal heat exchanger function and longevity. According to a report from the Heat Exchange Institute, inadequate maintenance can lead to a reduction in efficiency by up to 30%, severely impacting energy consumption and operational costs. Implementing efficient maintenance strategies can significantly improve performance, leading to reduced downtime and lower maintenance expenses.

One essential tip for maintaining heat exchanger efficiency is to perform routine inspections and cleaning. Accumulation of fouling materials can drastically hinder heat transfer and lead to excessive energy use. As per the U.S. Department of Energy, maintaining clean heat exchanger surfaces can enhance thermal performance by as much as 50%. Scheduling regular cleaning cycles based on operational conditions and usage can help sustain normal heat transfer rates.

Another crucial practice is monitoring operating conditions closely. Regularly checking parameters such as flow rates and temperature differentials ensures that the heat exchanger operates within its optimal range. This proactive approach not only prevents potential failures but also contributes to energy savings. The International Energy Agency reports that proper monitoring can reduce energy costs by an average of 10-25% in industrial settings. By integrating these maintenance practices into regular operational routines, facilities can maximize the efficiency and lifespan of their heat exchangers.

| Tip | Description | Frequency | Expected Outcome |

|---|---|---|---|

| Regular Cleaning | Remove fouling and deposits to ensure optimal flow. | Monthly | Improved heat transfer rates |

| Visual Inspections | Check for leaks or signs of damage. | Quarterly | Early detection of potential failures |

| Thermal Performance Testing | Measure and analyze temperature differentials. | Bi-annually | Identify inefficiencies and optimize settings |

| Check Fluid Levels | Ensure proper levels of coolant or heating fluid. | Monthly | Maintained pressure and flow rates |

| Monitor Pressure Drops | Watch for unusual pressure changes indicating blockage. | Continuous | Reduced risk of operational failures |

In the quest for enhancing heat exchanger efficiency, the incorporation of advanced materials plays a pivotal role. Recent studies indicate that the thermal conductivity of materials can significantly impact heat transfer performance. For instance, according to a report by the Global Heat Exchanger Market Analysis, materials such as copper and aluminum can improve heat transfer rates by up to 50% compared to traditional steel. This advancement not only boosts efficiency but also minimizes energy consumption, leading to substantial cost savings in industrial applications.

The development of composite materials, particularly those reinforced with graphene, is another breakthrough that promises to revolutionize heat exchanger technology. Research published in the Journal of Materials Science highlighted that graphene-enhanced composites can achieve thermal conductivities exceeding 2000 W/m·K, providing an unprecedented level of heat transfer efficiency. Utilizing these advanced materials in heat exchanger design could lead to more compact systems, reducing both physical space and material usage while achieving higher operational performance.

Furthermore, the trend towards eco-friendly materials, such as biodegradable polymers and recycled metals, is gaining traction in the industry. A study by the American Society of Mechanical Engineers found that integrating these sustainable materials into heat exchanger systems could reduce the overall carbon footprint by approximately 30%. By focusing on innovative material selections, industries can significantly enhance heat exchanger performance while promoting sustainability in thermal management solutions.

Innovative technologies are significantly enhancing the efficiency of heat exchangers, which are crucial for optimizing energy use across various industries. With the heat pump market projected to reach USD 147.29 billion by 2032, the need for advanced heat exchanger solutions is more critical than ever. Recent breakthroughs in 3D printing have shown that these modern methods can improve heat exchanger performance by 30% to 50% compared to traditional designs. This innovation not only enhances the overall efficiency but also allows for more complex designs that can cater to specific industrial needs.

To maximize heat exchanger efficiency, consider these essential tips: First, explore innovative design modifications such as incorporating twisted tubes or expanded metal baffles which optimize fluid dynamics. Second, invest in technologies for waste heat recovery that can dramatically reduce energy consumption and enable the valorization of otherwise lost energy. Lastly, adopting materials like graphene-coated surfaces can significantly enhance thermal conductivity and corrosion resistance, ultimately extending the lifespan of heat exchangers. As the industry trends towards sustainability, these advancements and strategies are paramount for achieving significant energy savings and reducing environmental impact.