In the quest for enhanced energy efficiency, industries worldwide are increasingly recognizing the critical role of industrial heat exchangers. According to a report by the International Energy Agency (IEA), industrial processes alone account for over 25% of global energy consumption, making it imperative to implement systems that optimize energy use. Specifically, industrial heat exchangers facilitate the recovery and reuse of waste heat, thereby minimizing energy costs and contributing to sustainable operations.

Moreover, a study published by the American Society of Mechanical Engineers (ASME) indicates that heat exchangers can improve energy efficiency by up to 30% in various industrial applications, significantly impacting the bottom line while also reducing carbon footprints. As industries strive to meet stringent environmental regulations and consumer demand for sustainable practices, the integration of advanced industrial heat exchangers not only addresses these challenges but also positions companies to remain competitive in a rapidly evolving market.

The following discussion will highlight the top five reasons why industrial heat exchangers are indispensable for optimizing energy efficiency across diverse sectors.

Industrial heat exchangers play a pivotal role in enhancing energy efficiency across various sectors. These systems are designed to transfer heat between two or more fluids, significantly improving thermal management in processes such as manufacturing, chemical processing, and power generation. According to the U.S. Department of Energy, heat exchangers can recover up to 90% of wasted energy in a facility, leading to substantial cost savings. Given that energy costs can account for up to 30% of total industrial operating expenses, optimizing heat exchange processes can markedly reduce this financial burden.

Furthermore, a report by the International Energy Agency (IEA) highlights that optimizing industrial heat recovery systems can lead to a reduction in greenhouse gas emissions by up to 20%. These devices not only contribute to operational efficiencies but also align with global sustainability efforts. As industries strive to minimize their carbon footprints, the integration of modern heat exchangers becomes even more critical. With advancements in technology, such as enhanced materials and designs, the efficiency of these systems continues to improve, further solidifying their importance in reducing energy costs and fostering a more sustainable industrial landscape.

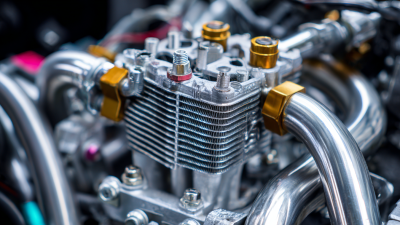

Heat exchangers play a vital role in enhancing energy efficiency across various industrial applications. There are several types of heat exchangers, including shell and tube, plate, air-cooled, and double pipe, each serving unique purposes based on the specific operational requirements.

For example, shell and tube heat exchangers are widely used in oil refineries and chemical plants due to their robust design and ability to handle high pressures, which can significantly reduce energy consumption while improving process efficiencies by approximately 10-15%, according to a report by the U.S. Department of Energy.

Moreover, plate heat exchangers offer a high surface area-to-volume ratio, making them ideal for applications such as HVAC systems and food processing. Their capacity to transfer heat efficiently allows industries to optimize energy usage significantly, reducing costs by as much as 20% in some processes.

In industrial settings, air-cooled heat exchangers are increasingly favored for their ability to operate without water, addressing the challenges of water scarcity and minimizing operational expenses.

Recent studies indicate that implementing the right heat exchanger technology can lead to a decrease in energy consumption by 5-30% depending on the application, underscoring their critical importance in energy management strategies within the industrial sector.

Efficient heat exchange systems play a vital role in enhancing energy efficiency across various industrial sectors. By optimizing thermal energy transfer, these systems reduce energy consumption, lower operational costs, and minimize environmental impact. Implementing these advanced systems not only leads to significant savings in energy bills but also improves productivity through better temperature regulation in manufacturing processes.

Tip: When selecting a heat exchanger, consider factors such as fluid compatibility, temperature range, and maintenance requirements to ensure maximum efficiency and longevity.

Moreover, efficient heat exchangers contribute to sustainable practices by reducing greenhouse gas emissions. Industries can significantly cut down on their carbon footprint by reusing waste heat, which otherwise would be lost. This not only aligns with corporate social responsibility goals but also meets increasing regulatory standards for energy efficiency.

Tip: Regular maintenance and timely upgrades of heat exchange systems can prevent performance degradation and unexpected downtime, ensuring consistent operational efficiency.

Innovative technologies are transforming the landscape of heat exchanger efficiency, driving significant advancements in energy savings and environmental sustainability. The recent introduction of energy-saving technologies, such as the IsoMat system, underscores the growing importance of thermal management solutions tailored for industrial applications. These developments not only enhance performance but also contribute to reducing overall energy consumption, aligning with global efforts towards a greener future.

The integration of cutting-edge designs, like electronically commuted fans paired with aluminum micro-channel heat exchangers, exemplifies how modernization can significantly boost efficiency. Such innovations utilize high-efficiency components that can outperform traditional designs, achieving efficiency gains that are 5,000 times greater. Moreover, partnerships in emerging sectors, including hydrogen power and aerospace, showcase a commitment to leveraging advanced thermal systems for sustainable energy solutions, echoing a shift towards more responsible industrial practices. Through these advancements, the role of heat exchangers in industry continues to evolve, becoming integral to achieving energy efficiency objectives.

| Dimension | Traditional Models | Innovative Models | Efficiency Improvement (%) |

|---|---|---|---|

| Heat Transfer Coefficient | 100 W/m²K | 150 W/m²K | 50% |

| Overall Heat Transfer Efficiency | 75% | 90% | 20% |

| Footprint Area | 20 m² | 15 m² | -25% |

| Energy Consumption | 500 kWh/month | 350 kWh/month | 30% |

| Maintenance Frequency | Every 3 months | Every 6 months | -50% |

Heat exchangers play a crucial role in enhancing energy efficiency within industrial processes, as demonstrated in various case studies highlighting successful optimization efforts. For instance, a chemical manufacturing plant in Texas implemented a detailed analysis of their heat exchanger network and identified opportunities for improving heat recovery. By upgrading to a more efficient heat exchange system, the facility managed to reduce its energy consumption by 30%, which translated into significant cost savings and a substantial reduction in greenhouse gas emissions.

Another successful case involves a food processing company in California that revamped their heat exchanger design to better suit their production needs. Through the integration of advanced control systems and high-performance materials, the company was able to optimize their thermal performance. As a result, they experienced a 25% increase in overall heat recovery efficiency, which not only minimized energy costs but also improved product quality and processing times. These examples illustrate how targeted heat exchanger optimization can lead to remarkable energy savings, fostering greater sustainability in industrial operations.