Heat exchanger systems play a vital role in numerous industries. Their effectiveness directly impacts energy consumption and operational costs. Therefore, enhancing heat exchanger efficiency is crucial for overall performance.

Many factors influence heat exchanger efficiency. One critical aspect is the design of the system. Outdated designs may lead to reduced heat transfer rates. Another key factor is proper maintenance. Neglect can result in fouling, decreasing efficiency. Regular inspections can help identify problems early.

Improving heat exchanger efficiency is an ongoing challenge. Operators often overlook small adjustments that can yield significant results. Simple modifications, like optimizing flow patterns, can enhance performance. Reflecting on current practices can reveal insights for improvement. Always seek ways to refine your approach.

Heat exchangers are critical components in many industrial processes. They transfer heat between two fluids without mixing them. Understanding their basic functions helps improve overall system efficiency.

One effective way to enhance efficiency is to regularly clean the heat exchanger surfaces. Scale buildup can impair heat transfer. Frequent inspections can identify blockages early. This prevents bigger issues down the road.

Optimizing flow rates also matters. Too fast or too slow can reduce efficiency. Balance is key. Adjusting the flow can lead to significant energy savings. Remember, small changes can yield big results.

When selecting materials, consider thermal conductivity. Using the right materials can maximize heat transfer. Yet, this is often overlooked. Reflect on the materials in use. Are they the best choice for your application?

Heat exchanger efficiency is crucial for industrial performance. Many factors can influence this efficiency. One major factor is fouling. According to a recent industry report, fouling can reduce heat transfer efficiency by up to 30%. This buildup of unwanted materials on heat exchanger surfaces can hinder performance over time. Regular maintenance and cleaning are essential. However, some facilities often overlook this aspect, leading to suboptimal operations.

Another key factor is flow arrangement. The choice of counterflow, parallel flow, or crossflow directly impacts heat transfer rates. A study revealed that counterflow designs can achieve up to 25% more efficient heat exchange than parallel flow under similar conditions. Choosing the correct design may seem straightforward, yet many engineers don't revisit these decisions as systems evolve.

Temperature differences between fluids also play a critical role. The effectiveness of a heat exchanger improves with a larger temperature gradient. Yet, not all systems can operate at optimal temperature differences due to safety or materials limits. Striking the right balance presents a constant challenge, forcing operators to reevaluate their processes. Understanding these factors is vital for enhancing overall heat exchanger performance.

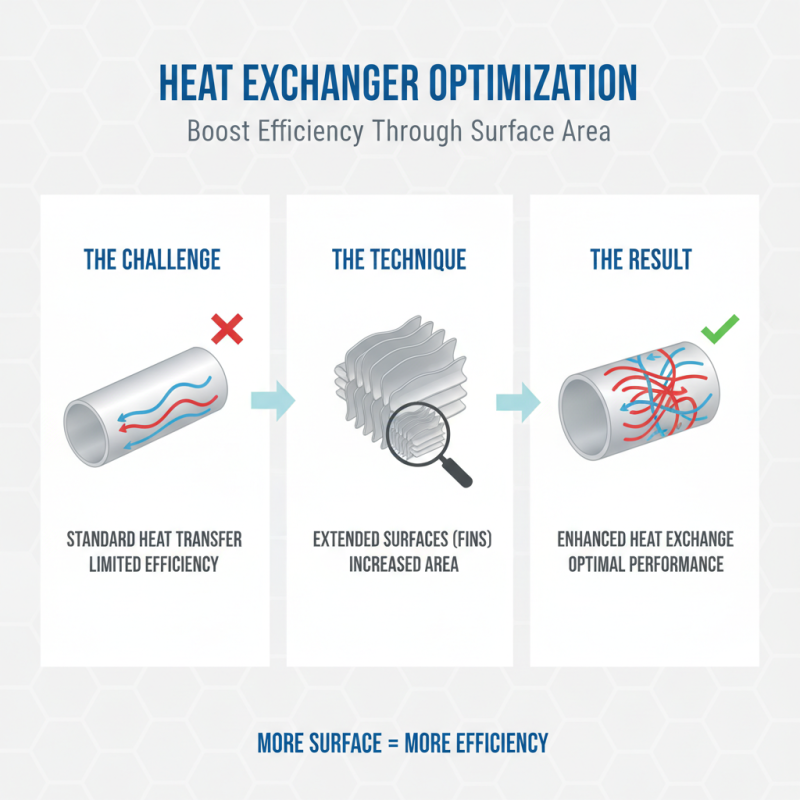

Heat exchangers play a vital role in numerous industrial processes. Optimizing heat transfer in these systems is essential for efficiency. One technique involves enhancing surface area. Increasing the surface area of heat transfer surfaces can significantly improve heat exchange rates. This can be achieved through the use of extended surfaces or fins.

Another method is to enhance fluid flow. Turbulent flow typically promotes better heat transfer than laminar flow. Adding elements like baffles can disrupt flow patterns and promote turbulence. However, care is required. Excessive turbulence can increase pressure drops and lead to energy losses. Finding the right balance is crucial.

Regular maintenance is also essential. Accumulation of deposits can reduce efficiency. Routine cleaning prevents fouling and maintains heat transfer capabilities. Monitoring temperature differences and flow rates can help identify inefficiencies early. Sometimes, data reveals issues that need timely attention. A holistic approach often leads to better results. Embracing a mindset of continuous improvement in heat exchanger operations is beneficial.

Regular maintenance is essential for maximizing heat exchanger efficiency.

Cleaning the heat exchanger periodically helps remove dirt and scale buildup. These deposits can significantly hinder heat transfer, leading to lower performance.

Inspecting seals and gaskets ensures that there are no leaks. A small leak might seem insignificant, but it can cause substantial energy loss.

Monitoring flow rates is also vital. An irregular flow can indicate problems in the system. Over time, this can lead to uneven heating or cooling.

Keeping accurate records of performance metrics allows for better assessment. It helps identify when maintenance is overdue.

Some operators may overlook minor fluctuations. Yet, these can lead to bigger issues if neglected.

Performing routine checks on temperature differentials ensures optimal operation. Ignoring these checks can result in decreased efficiency.

Lastly, training staff on proper handling and operation can prevent mistakes. Investing in employee knowledge pays off.

Untrained personnel might not recognize early warning signs. Enhancing efficiency requires commitment and diligence.

Small lapses can lead to noticeable drops in performance.

Heat exchangers are critical in many industries, yet inefficiencies often go unnoticed. According to a recent report by the U.S. Department of Energy, improper maintenance can lead to a 20% drop in performance. Innovations in materials are addressing this issue directly. For instance, advanced alloys enhance thermal conductivity, thereby improving heat transfer efficiency. These materials resist corrosion and extend the life of heat exchangers.

Incorporating technologies like digital twin modeling can offer real-time insights. These simulations help identify potential performance issues before they escalate. Moreover, predictive maintenance, enabled by Internet of Things (IoT) sensors, can reduce downtime significantly. Research indicates that proactive maintenance can save up to 30% on operational costs. Yet, some facilities remain hesitant to adopt these technologies, sometimes due to the initial investment.

Although these advancements hold promise, they require careful integration. Some systems struggle with compatibility when new technologies are introduced. Transitioning to more efficient designs may seem daunting. So, industry players must weigh the benefits against potential challenges. The road to enhanced heat exchanger performance is not without bumps, but innovation is key to moving forward.