In the rapidly advancing technological landscape, effective thermal management has emerged as a critical factor for the performance and longevity of electronic systems. According to a recent report by MarketsandMarkets, the global thermal management market is projected to reach USD 19.47 billion by 2025, illustrating a compound annual growth rate of 10.5%. Among various solutions, Thermal Management Coolers play a pivotal role by dissipating excess heat generated by electronic components, thereby preventing overheating and potential failures. As the demand for high-performance computing, electric vehicles, and renewable energy technologies intensifies, understanding the key features and innovative designs of these coolers becomes essential for industry stakeholders. This blog delves into the essential aspects of Thermal Management Coolers, highlighting their importance, key features, and industry insights to enhance operational efficiency and product reliability.

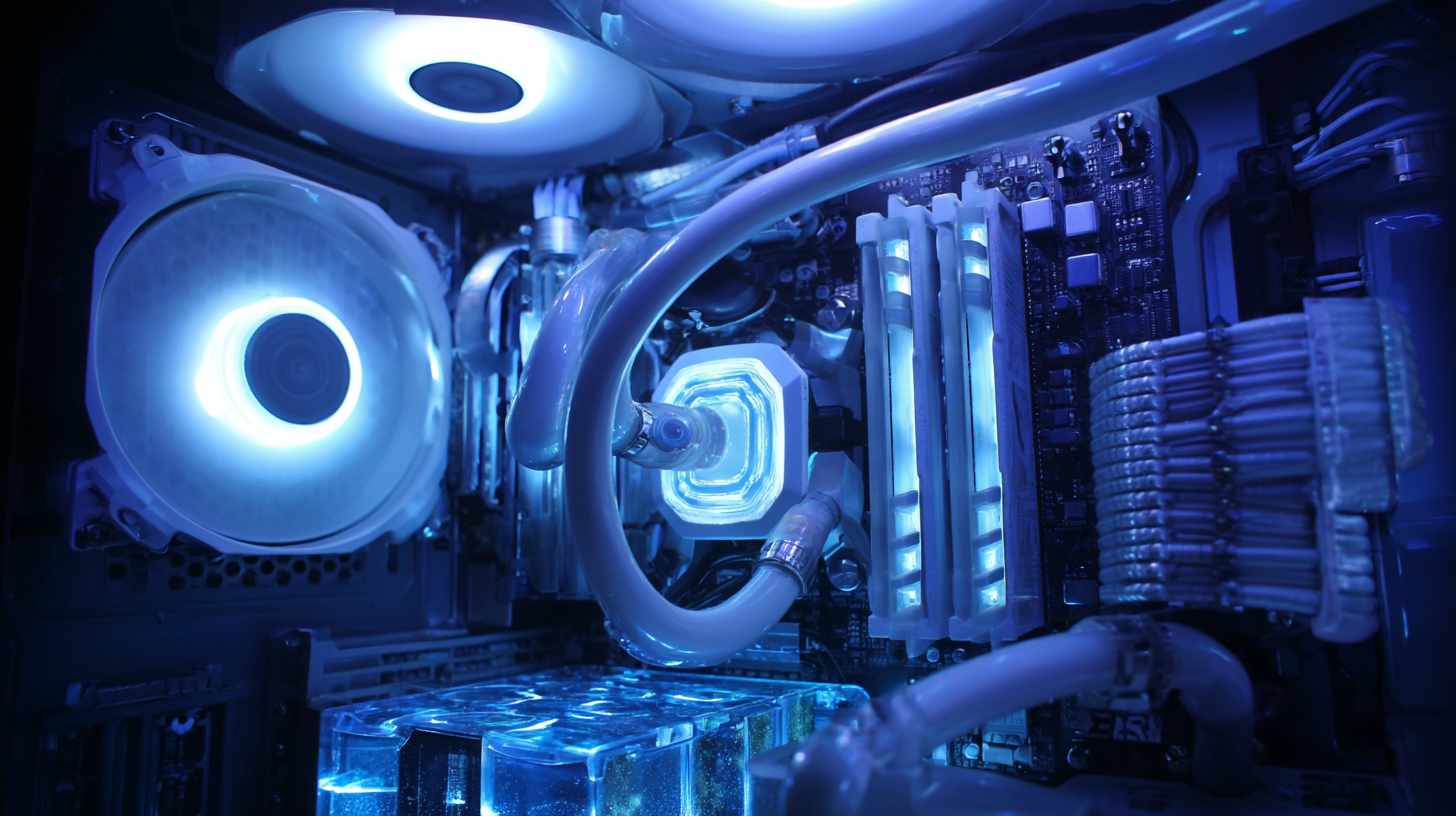

When selecting the right thermal management cooler, several key considerations must be taken into account to ensure optimal performance and longevity of electronic components. One of the most critical factors is the cooler's thermal performance, often quantified by its thermal resistance value (°C/W). According to a study by MarketsandMarkets, the global thermal management market is projected to reach USD 8.4 billion by 2025, driven largely by the increasing demand for efficient cooling solutions in the growing electronics and automotive sectors.

Another important aspect to consider is the cooler's noise level, especially in applications where sound is a concern, such as in consumer electronics and residential settings. Industry reports indicate that coolers with advanced fan control technology can reduce noise levels by up to 30% compared to traditional models. Additionally, the physical dimensions and weight of the cooler are crucial, as they must fit within the design constraints of the device while still offering robust thermal management capabilities. Adopting a cooler that optimally balances these factors can lead to improved reliability and improved overall efficiency in performance.

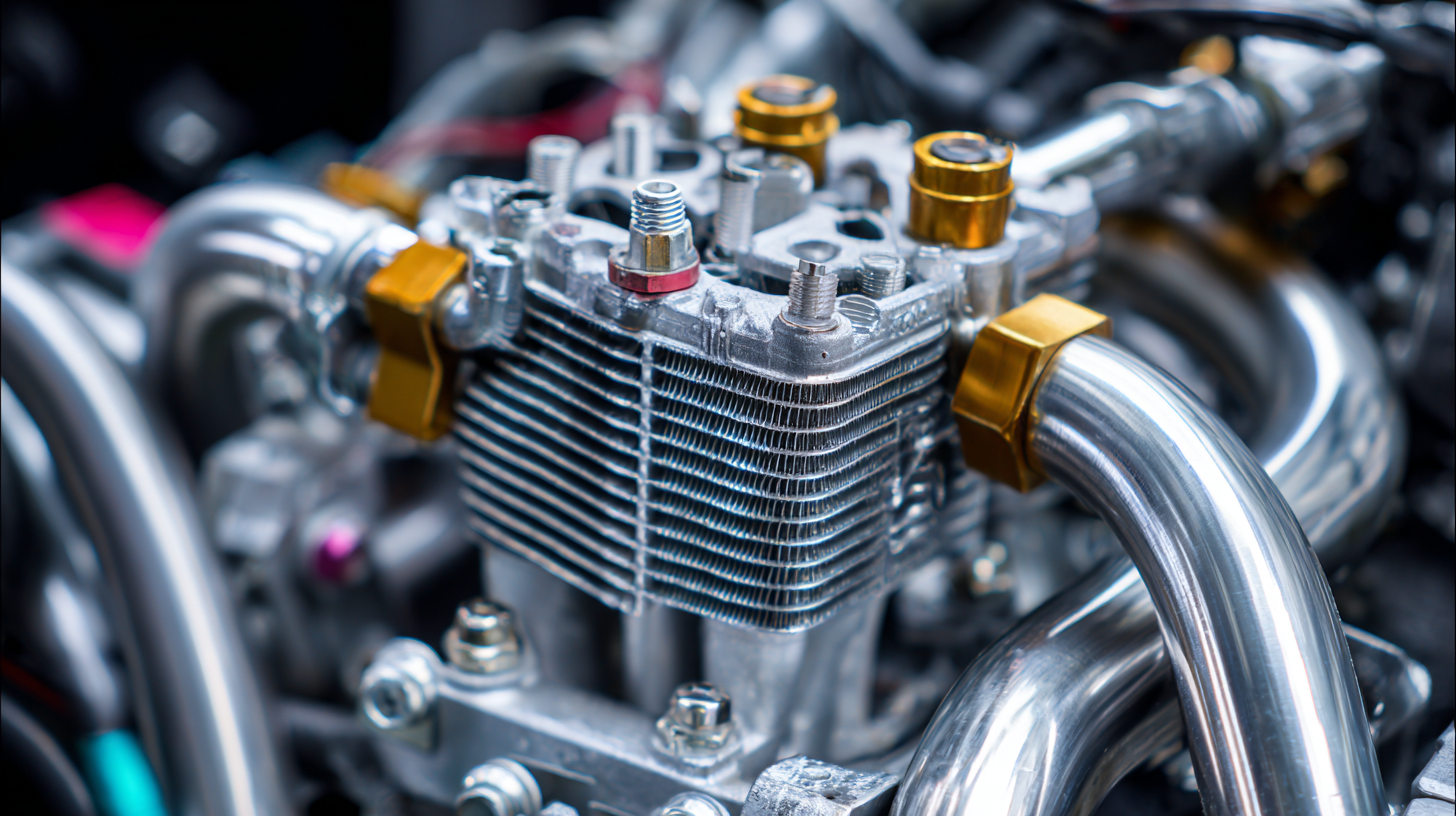

Thermal management is crucial for the performance and longevity of electronic devices, making the choice of coolers an essential consideration. When selecting a cooler, several key features can significantly enhance thermal performance. One of these features is the material composition. Aluminum and copper are popular choices due to their excellent thermal conductivity. Opting for a cooler made from these materials can drastically improve heat dissipation, ensuring that your devices operate within safe temperature limits.

Tip: Regular maintenance of coolers is vital. Dust and debris can accumulate over time, reducing efficiency. Make a habit of periodically cleaning your coolers to maintain optimal performance.

Another essential feature is airflow design. Efficient airflow can be achieved through strategically placed fans and vents, allowing for better circulation of air around heat-generating components. When evaluating coolers, consider those with adjustable fan speeds and monitoring capabilities; this allows for tailored cooling based on current temperature levels.

Tip: Monitor the temperature of your components regularly, especially during high-performance tasks. This will help you identify any cooling issues early, allowing you to take action before overheating occurs.

In recent years, the thermal management technology industry has experienced significant evolution, driven by the growing demand for efficiency in various sectors, including electronics, automotive, and renewable energy. As devices become smaller and more powerful, effective cooling solutions have become critical to maintaining performance and reliability. Industry trends indicate a shift toward advanced materials and innovative designs that enhance heat dissipation while optimizing space and cost. For instance, the integration of phase change materials and active cooling methods, such as thermoelectric coolers, has gained popularity for their efficiency in managing high heat loads.

Furthermore, sustainability has emerged as a pivotal factor influencing thermal management technologies. Manufacturers are increasingly focusing on eco-friendly materials and energy-efficient cooling solutions, which not only comply with regulatory standards but also appeal to environmentally conscious consumers. This trend reflects a broader commitment to reducing carbon footprints while enhancing device longevity. As we observe these developments, it is clear that the future of thermal management is promising, with ongoing advancements poised to tackle the challenges of heat management in an ever-evolving technological landscape.

This chart displays the growth trends in the thermal management technologies market, focusing on key features such as efficiency, size, and operating temperature ranges of cooling solutions over the past five years.

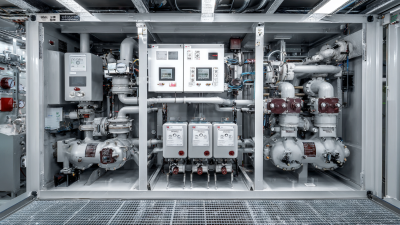

Effective cooling is crucial for the longevity of various types of equipment, from industrial machinery to consumer electronics. Overheating can lead to significant performance degradation, reduced efficiency, and ultimately, hardware failure. By maintaining optimal operating temperatures through advanced thermal management coolers, equipment can perform at its peak for longer periods, minimizing downtime and maintenance costs. This proactive approach to cooling not only ensures reliable operation but also enhances overall productivity in industries reliant on sensitive equipment.

Moreover, the design and materials used in thermal management systems play a pivotal role in their effectiveness. Features such as heat sinks, fans, and liquid cooling solutions must be carefully selected to match the specific thermal needs of the equipment they serve. By investing in high-quality thermal management solutions, businesses can safeguard their investments, extend equipment life cycles, and improve the sustainability of their operations. This understanding of cooling systems is essential for any company looking to optimize performance and reduce the total cost of ownership of their valuable assets.

Thermal management coolers play a vital role in maintaining optimal operating conditions for electronic components, especially in industries where heat generation is a significant issue. To ensure the longevity and efficiency of these systems, regular maintenance is crucial. According to a report by MarketsandMarkets, the thermal management market is projected to reach USD 11.5 billion by 2026, emphasizing the increasing reliance on effective thermal solutions. One of the best practices for maintenance includes routinely checking airflow paths and ensuring that dust and debris do not obstruct these areas. An efficient airflow can reduce the operational load on coolers by up to 20%, improving energy savings as well.

Optimization of thermal management coolers can be achieved through monitoring and adapting to operational changes. The implementation of IoT sensors can provide real-time data on temperature fluctuations, allowing for proactive measures. A study from Frost & Sullivan projects that such smart systems could reduce energy consumption by as much as 30% in large industrial settings. Additionally, investing in high-quality thermal interface materials can lead to better heat dissipation, further enhancing the cooler's performance. By focusing on these maintenance and optimization practices, businesses can ensure their thermal management systems are both robust and efficient, ultimately leading to reduced operational costs and minimized downtime.

| Feature | Description | Importance | Best Practices for Maintenance |

|---|---|---|---|

| Cooling Efficiency | Measures how effectively the cooler can dissipate heat. | Crucial for preventing overheating and maintaining operational stability. | Regularly check coolant levels and ensure airflow is not obstructed. |

| Material Quality | The materials used in the construction of the cooler affect durability and performance. | High-quality materials enhance longevity and resistance to corrosion. | Inspect for wear and tear and replace damaged components promptly. |

| Size and Design | The dimensions and configuration of the cooler should fit the application requirements. | Optimal design prevents hotspots and promotes even temperature distribution. | Ensure there's adequate space around the cooler for airflow and consider upgrades when necessary. |

| Maintenance Accessibility | Ease of access for routine checks and servicing. | Facilitates timely maintenance, which is essential for performance longevity. | Designate clear access points and schedule regular inspections. |

| Energy Efficiency | The cooler's power consumption in relation to its cooling output. | Reducing energy use lowers operational costs and environmental impact. | Invest in energy-efficient models and conduct regular energy audits. |