In the realm of thermal energy transfer, the significance of heat exchanger efficiency can hardly be overstated. As industries and technologies evolve, the demand for systems that maximize thermal performance while minimizing energy loss has become increasingly critical. Understanding the various types of heat exchangers and their operational mechanisms is key to enhancing heat exchanger efficiency, which directly impacts overall system sustainability and cost-effectiveness.

This guide delves into the multifaceted world of heat exchangers, examining how different designs—from shell-and-tube to plate and fin configurations—can optimize performance. By exploring the factors that influence efficiency and the applications of diverse heat exchanger types, we aim to equip readers with the knowledge necessary to make informed decisions in selecting and operating these essential components in various industrial processes.

In the evolving landscape of thermal management, understanding the various types of heat exchangers is crucial for maximizing efficiency across diverse applications. Recent advancements highlight the significance of tubular, plate, and shell-and-tube designs, each catering to specific thermal processes. Notably, a comprehensive review of advancements showcases tubular heat exchangers' prowess in energy storage, where they effectively facilitate the transfer of thermal energy in systems like heat pumps and thermal batteries.

In automotive applications, innovative design methodologies such as fluid-thermal-electric multiphysics modeling are optimizing heat exchangers for thermoelectric generators, enhancing vehicle efficiency. This optimization aligns with findings in numerical studies that focus on the hydrodynamics and heat transfer characteristics of advanced shell-and-tube configurations. For instance, the recent development of a double-layer tube type heat exchanger for lead-bismuth reactors illustrates the industry's shift towards incorporating advanced materials like graphene-based nanofluids to improve thermal interface performance.

Furthermore, the rise of artificial intelligence in additive manufacturing is opening new frontiers for custom-designed heat exchangers, thus enabling tailored solutions that meet specific industrial needs. These innovations aim to elevate heat exchanger performance by prioritizing sustainability and operational efficiency, highlighting a critical focus for future thermal system designs.

Plate heat exchangers have emerged as crucial components in various industries, optimizing thermal performance and enhancing energy efficiency. Their design allows for a large surface area in a compact structure, which facilitates effective heat transfer between two fluids. In contrast to traditional shell-and-tube designs, plate heat exchangers offer improved thermal efficiency, resulting in lower operational costs and energy consumption. This efficiency is particularly vital in industries such as food and beverage, pharmaceuticals, and HVAC systems, where maintaining precise temperature control is essential.

In the food and beverage industry, for instance, plate heat exchangers enable quick and efficient pasteurization of products while preserving their quality. The design minimizes thermal resistance, allowing for faster heating and cooling cycles. Similarly, in the pharmaceutical sector, they help maintain stringent temperature requirements for various processes, ensuring product integrity and safety.

With advancements in material technology, modern plate heat exchangers are also more durable and resistant to fouling, further enhancing their efficiency and lifespan. As industries continue to seek energy-efficient solutions, the role of plate heat exchangers becomes increasingly vital for maximizing performance and sustainability.

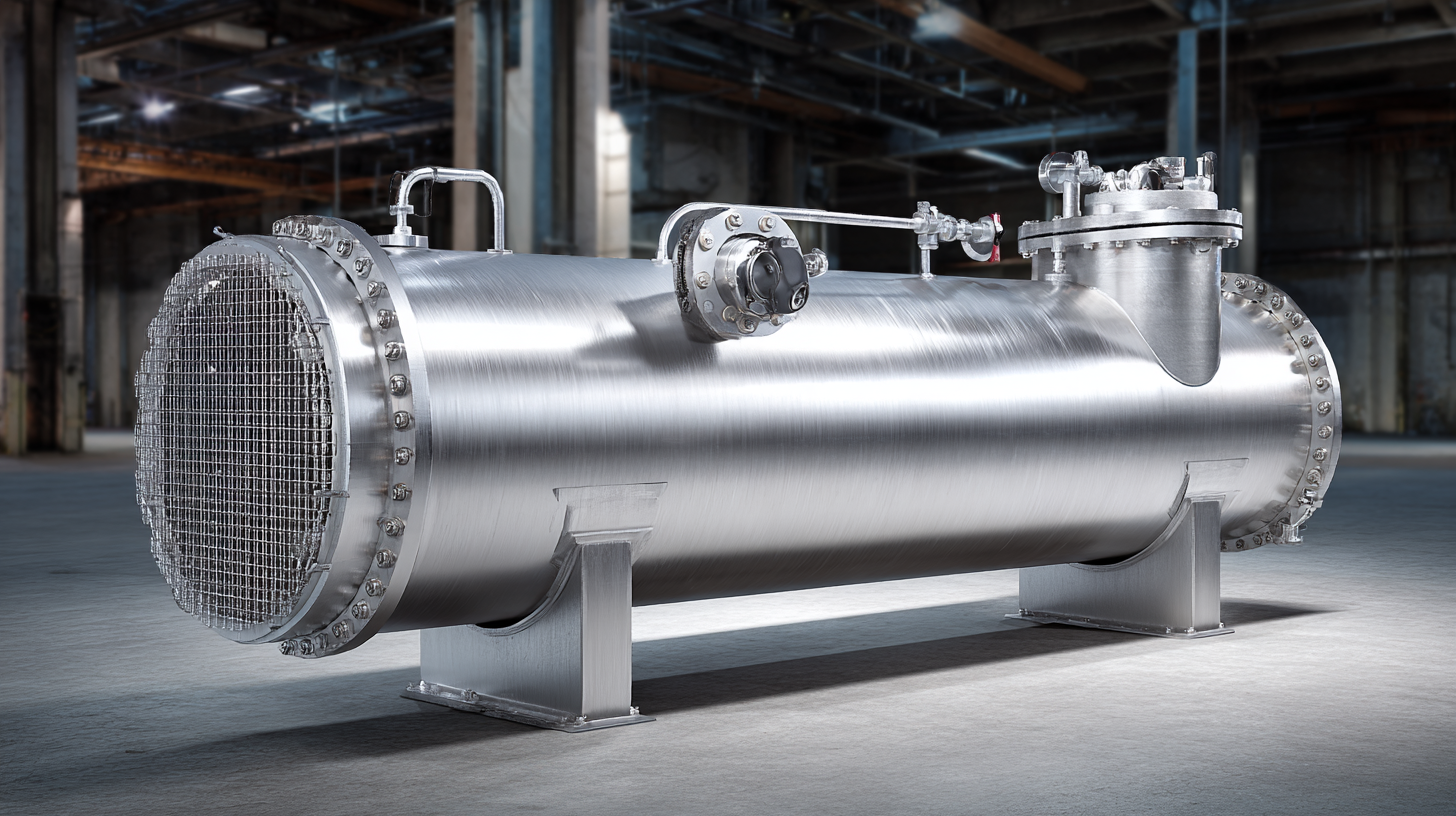

Shell and tube heat exchangers are pivotal in enhancing thermal performance across a variety of industries. These systems consist of a series of tubes, one set carrying the hot fluid and the other the cold fluid, allowing for efficient heat transfer. The design is particularly advantageous because the large surface area allows for effective heat exchange while maintaining a compact footprint. Additionally, the ability to easily clean and maintain these exchangers contributes to their long lifespan and consistent performance.

Shell and tube heat exchangers are pivotal in enhancing thermal performance across a variety of industries. These systems consist of a series of tubes, one set carrying the hot fluid and the other the cold fluid, allowing for efficient heat transfer. The design is particularly advantageous because the large surface area allows for effective heat exchange while maintaining a compact footprint. Additionally, the ability to easily clean and maintain these exchangers contributes to their long lifespan and consistent performance.

The efficiency of shell and tube heat exchangers can be maximized by optimizing factors such as flow rates, temperature differentials, and the arrangement of the tubes. The use of multiple shell passes can further improve heat transfer efficiency by promoting turbulent flow and minimizing temperature differences along the exchange surface. As industries increasingly focus on energy efficiency and sustainability, shell and tube heat exchangers remain a cornerstone technology, leveraging innovative designs and materials to meet modern demands while significantly reducing operational costs.

When it comes to maximizing heat exchanger efficiency, a critical comparison exists between air-cooled and water-cooled heat exchangers. Air-cooled heat exchangers utilize ambient air to dissipate heat, making them particularly advantageous in environments where water availability is limited. Their straightforward design and lower operational costs often make them the preferred choice in regions with cool climates, where air temperatures can be effectively utilized for cooling purposes. However, their efficiency can be significantly affected by high ambient temperatures, which may hinder their heat transfer capabilities during the peak summer months.

On the other hand, water-cooled heat exchangers leverage the superior thermal conductivity of water to achieve higher efficiency levels. They can often operate effectively in scenarios with elevated thermal loads, making them ideal for industrial applications where constant cooling is critical. Despite their superior performance, water-cooled systems require a constant water source and involve more complex maintenance due to potential water quality issues and the need for additional components like cooling towers.

In summary, the choice between air-cooled and water-cooled heat exchangers largely depends on the specific application and environmental conditions, each presenting unique advantages and challenges that can affect overall operational efficiency.

Heat exchanger efficiency is influenced by numerous factors, particularly the design and materials used. Recent research highlights innovative methods to enhance performance of various heat exchangers. For instance, the introduction of a mesh-net insert in air-to-air plate heat recovery units has demonstrated significant improvements in thermal efficiency. This modification not only boosts effectiveness but also addresses economic aspects, making it a viable solution for commercial applications. Such enhancements underscore the importance of design optimizations in maximizing heat exchanger performance.

Furthermore, studies have shown that the geometry of heat exchangers, such as helically coiled tubes, can greatly influence thermal characteristics and heat transfer efficiency. For large-scale geothermal projects, the integration of medium-deep borehole systems with different heat storage techniques has proven effective in harnessing waste heat more efficiently. The exploration of thermally conductive composites as alternative materials for polymer heat exchangers also suggests that factors like corrosion resistance and anti-fouling properties are crucial for maintaining long-term efficiency. As the industry evolves, these advancements signal a move towards more sustainable and effective thermal management solutions.