As we approach the 2025 China Import and Export Fair, a pivotal event for innovation and trade, the spotlight will undoubtedly shine on advancements in various industries, with a particular emphasis on Heat Exchanger Tube technologies. These essential components play a critical role in enhancing energy efficiency and thermal performance across multiple sectors, including manufacturing, power generation, and HVAC systems. The 138th session of this prestigious fair is set to showcase groundbreaking designs, materials, and manufacturing techniques that promise to revolutionize how heat exchangers are integrated into modern systems. With escalating energy demands and environmental concerns, the innovations presented at the fair will not only highlight the latest developments in Heat Exchanger Tube manufacturing but also reflect the industry's commitment to sustainability and performance optimization. As global competition intensifies, these advancements are key to maintaining excellence in energy transfer solutions, making the 2025 fair a must-attend for industry professionals and stakeholders eager to explore the future of heat exchange technology.

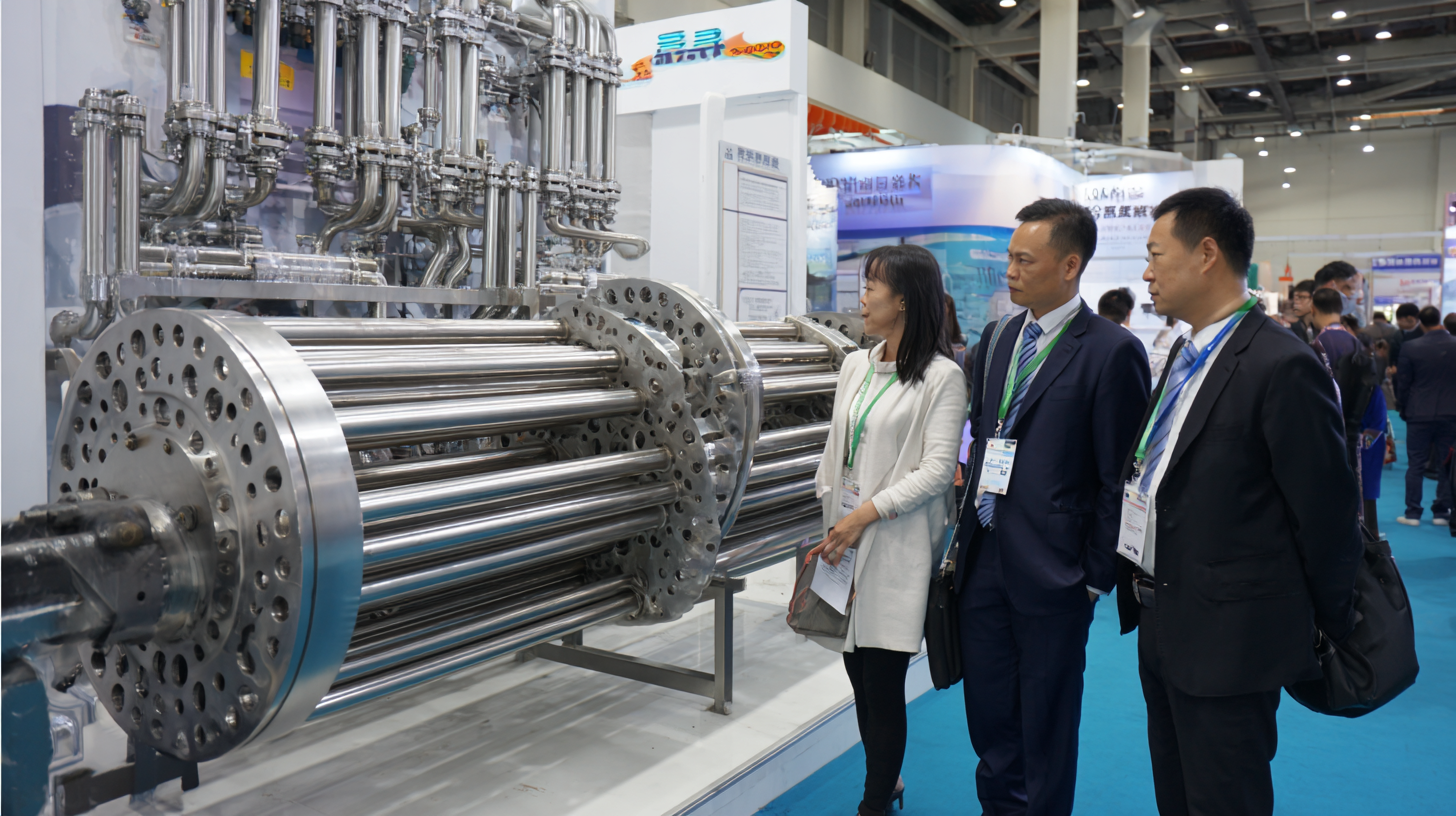

At the 2025 China Import and Export Fair, the spotlight will be on groundbreaking innovations in heat exchanger tube designs that aim to significantly enhance thermal efficiency. With the growing demand for energy-efficient systems across various industries, manufacturers are focusing on integrating advanced materials and innovative geometries into their designs. These new tubes are engineered using state-of-the-art techniques such as 3D printing and nanomaterial integration, which allow for improved heat transfer capabilities while simultaneously reducing pressure drop.

One of the most exciting developments in this realm is the implementation of enhanced surface designs. These modifications create turbulence within the fluid flow, facilitating better heat exchange without increasing the energy consumption. Additionally, the use of eco-friendly materials aligns with global sustainability goals and addresses the increasing regulatory pressures for lower environmental impact. As these innovations are showcased, they are set to inspire further advancements in the field, helping industries optimize their thermal management processes and reduce operational costs, ultimately leading to a greener future for heat exchange technology.

The 2025 China Import and Export Fair will be an important platform for showcasing the latest innovations in heat exchanger tube technology, particularly with a focus on emerging materials and technologies that are enhancing performance. Recent industry reports indicate a significant shift towards advanced materials, such as titanium alloys and composite materials, which can withstand extreme conditions and improve thermal efficiency. For instance, research from the Global Heat Exchanger Market Report predicts that advancements in materials will drive a 15% increase in heat exchanger performance by 2027, outpacing traditional metal options.

In addition to materials innovation, technological advancements are also pivotal in optimizing heat exchanger design. Computational fluid dynamics (CFD) and additive manufacturing are revolutionizing how heat exchangers are produced and customized. According to a recent study by MarketsandMarkets, the demand for heat exchangers utilizing these technologies is expected to grow at a CAGR of 11.2% from 2023 to 2028. Such innovations not only promote better heat transfer efficiency but also lead to lighter, more compact designs, making them suitable for a wider range of applications, from industrial processes to renewable energy systems.

| Material Type | Thermal Conductivity (W/m·K) | Corrosion Resistance | Weight Reduction (%) | Cost (USD per kg) |

|---|---|---|---|---|

| Copper-Nickel Alloy | 400 | Excellent | 15 | 5.50 |

| Titanium | 300 | Excellent | 10 | 15.00 |

| Aluminum | 205 | Good | 25 | 3.00 |

| Stainless Steel | 16 | Very Good | 5 | 4.50 |

| Composite Materials | 250 | Good | 30 | 8.00 |

| Carbon Steel | 50 | Poor | 0 | 2.50 |

The heat exchanger tube market is poised for substantial growth over the next five years, offering intriguing opportunities for innovation. With global market size projected to expand significantly, from $88 billion in 2018 to an estimated $16.1 billion by 2032, the compound annual growth rate (CAGR) stands at 4.45%. This growth is indicative of the increasing demand for energy efficiency and sustainable solutions across various industries, driving investments in new materials and technology enhancements in heat exchanger designs.

Furthermore, the upcoming 2025 China Import and Export Fair will spotlight the latest innovations in heat exchanger tube technology, providing a platform for manufacturers to showcase cutting-edge solutions that address the evolving market needs. Key trends include the adoption of advanced materials that enhance thermal conductivity and corrosion resistance, as well as smart technologies that enable real-time monitoring and performance optimization. These innovations are expected to not only improve energy recovery processes but also contribute to a greener and more efficient industrial landscape in the years to come.

The future of heat exchanger tube innovations is increasingly influenced by sustainability and stringent regulatory standards. As industries grapple with the urgent need to reduce carbon emissions and energy consumption, manufacturers are turning to advanced materials and technologies that enhance the efficiency and longevity of heat exchanger tubes. Innovations such as lightweight alloys, enhanced coatings, and improved manufacturing processes are vital in meeting these environmental demands while also adhering to new guidelines imposed by governments and international organizations.

Moreover, as the 2025 China Import and Export Fair approaches, the spotlight will be on how global players adapt to these regulatory pressures. Companies are now investing in research and development to create products that not only comply with the latest environmental regulations but also pioneer sustainable practices in the heat exchange sector. Collaboration across industries is essential to drive innovation, sharing best practices, and forging partnerships that prioritize eco-friendly solutions. The outcome of these efforts will undoubtedly shape the market landscape, leading to more responsible production methods and a stronger commitment to sustainability in the heat exchanger industry.

The digitalization of the manufacturing sector is poised to transform heat exchanger tube operations and maintenance significantly. According to a report by MarketsandMarkets, the market size for digital twin technology in industrial applications is projected to reach USD 26.4 billion by 2026, with a compound annual growth rate (CAGR) of 37.5% from 2021 to 2026. This technology allows real-time monitoring and predictive maintenance, enhancing the operational efficiency of heat exchangers. By integrating smart technologies into heat exchanger systems, companies can reduce downtime and minimize maintenance costs by up to 20%, as per industry estimates.

Moreover, the implementation of IoT (Internet of Things) in heat exchanger tube management offers unprecedented insights into operational performance. Research from Fortune Business Insights indicates that the global IoT in manufacturing market is expected to grow from USD 13.6 billion in 2020 to USD 38.2 billion by 2027, reflecting a significant shift towards intelligent systems. These advancements not only facilitate better monitoring of temperature and flow but also enable early detection of potential failures, which is crucial for maintaining the integrity and efficiency of heat transfer processes. As we approach the 2025 China Import and Export Fair, the focus on these innovations will likely drive more companies to leverage digital tools for enhancing their heat exchanger tube operations.