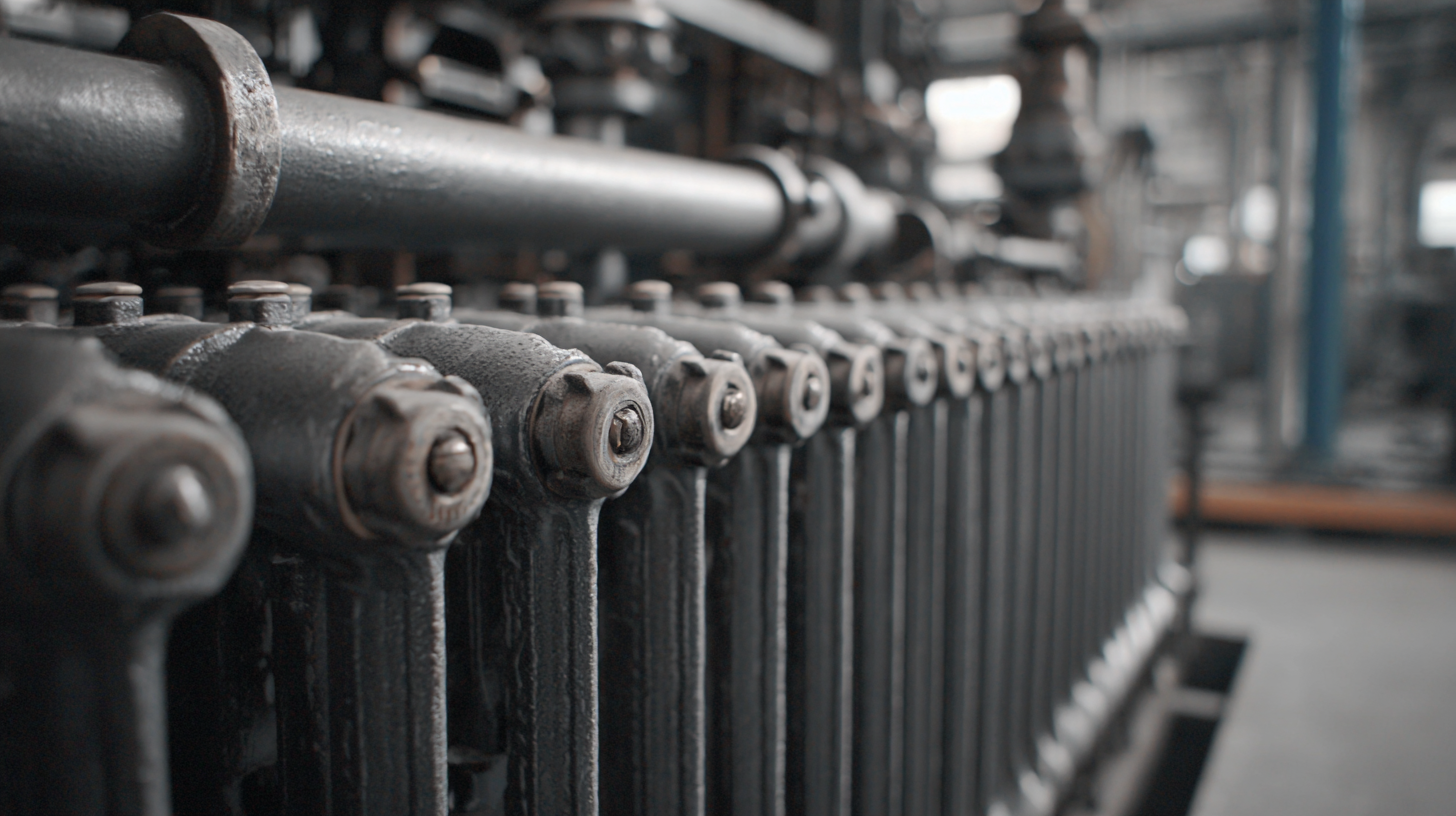

In today's competitive automotive and industrial markets, ensuring excellence in Radiator Quality Control is paramount for manufacturers aiming to meet stringent performance and safety requirements. According to the global market research report by MarketsandMarkets, the demand for high-quality radiators is projected to grow at a CAGR of 5.8% from 2021 to 2026, driven by the increasing emphasis on efficiency and sustainability. Advanced testing techniques, such as computational fluid dynamics and non-destructive testing, have become integral in identifying potential defects and ensuring reliability. Moreover, adhering to industry standards, such as ISO 9001 and AS9100, not only enhances product quality but also builds customer trust and satisfaction. By implementing robust quality control measures, manufacturers can significantly reduce warranty claims, enhance operational efficiency, and foster long-term growth in an increasingly quality-conscious market.

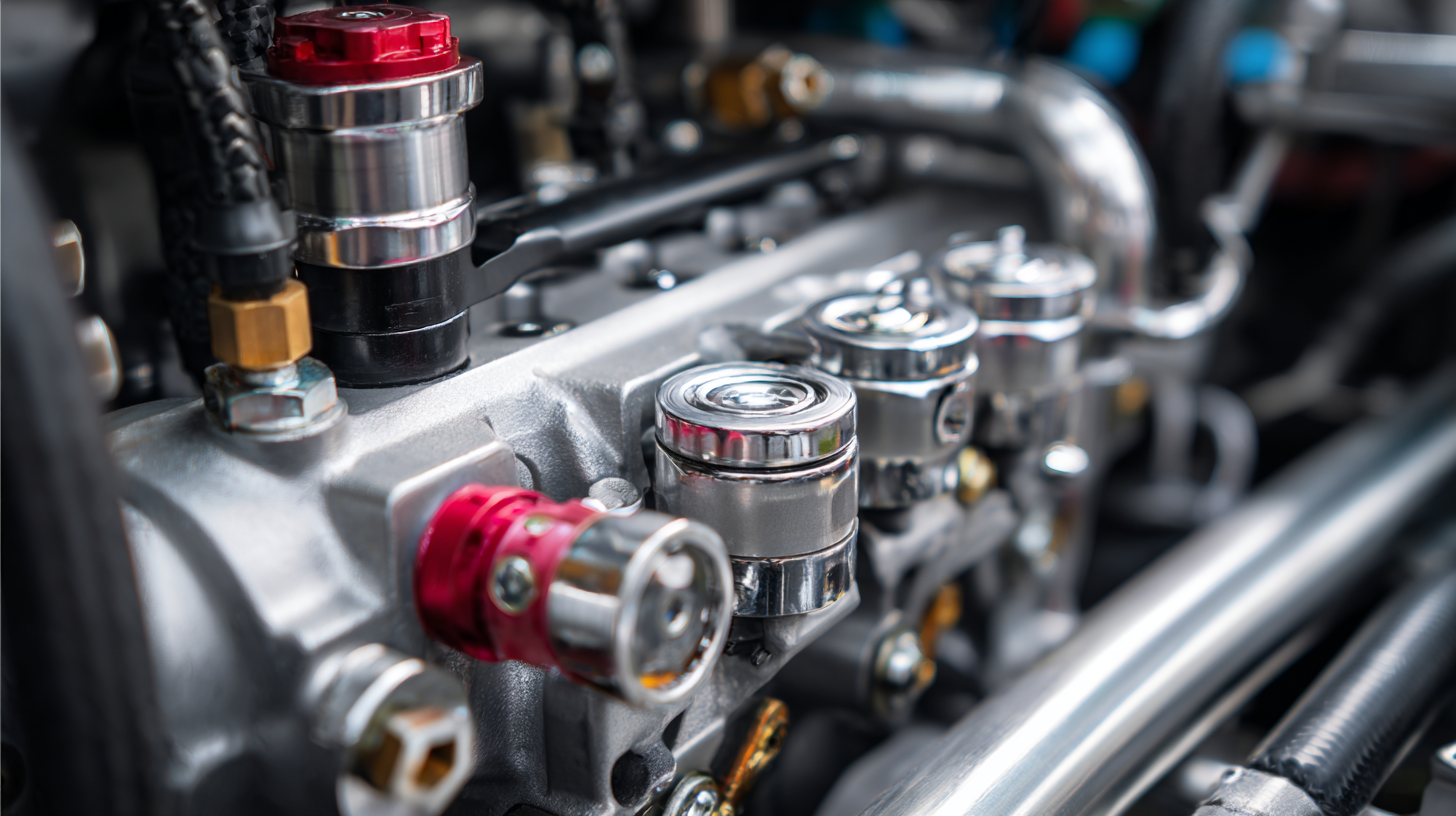

Innovative testing methods play a crucial role in ensuring the quality of radiators, particularly as industry standards continue to evolve. These methods encompass advanced techniques such as computational fluid dynamics (CFD) simulations, which allow manufacturers to predict thermal performance and fluid dynamics even before physical prototypes are created. By utilizing CFD, companies can efficiently optimize radiator designs for maximum heat transfer and durability, significantly reducing development time and costs.

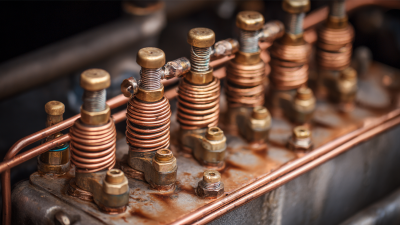

Another key advancement in radiator quality assurance is the implementation of non-destructive testing (NDT) techniques, including ultrasonic and X-ray inspections. These methods enable manufacturers to identify potential flaws without compromising the integrity of the radiator. As a result, any structural weaknesses or material defects can be addressed early in the production process. By embracing these innovative testing approaches, manufacturers not only adhere to stringent quality standards but also enhance the reliability and performance of their radiators in real-world applications.

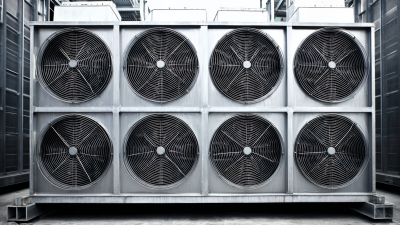

In the ever-evolving landscape of radiator manufacturing, integrating digital solutions has emerged as a pivotal strategy for enhancing quality control and operational efficiency. By leveraging advanced technologies such as IoT (Internet of Things) and AI (Artificial Intelligence), manufacturers can monitor production processes in real-time, ensuring that every aspect of radiator assembly meets stringent quality standards. These digital tools facilitate proactive identification of defects and inconsistencies, allowing for immediate corrective actions and minimizing waste, ultimately leading to superior product quality.

Moreover, the integration of digital solutions streamlines the overall manufacturing process by automating routine tasks and improving data management. Digital twins, for example, enable manufacturers to create virtual models of the radiator production line, simulating various scenarios to optimize performance prior to implementation. This not only reduces the risk of errors but also enhances collaboration among teams, as real-time data sharing fosters a more cohesive approach to quality assurance. Embracing these digital advancements positions radiator manufacturers to meet the challenges of today's market while maintaining excellence in product quality.

| Testing Technique | Description | Industry Standard | Digital Solution |

|---|---|---|---|

| Hydraulic Pressure Testing | Evaluates the strength and leak resistance of radiators under high pressure. | ISO 21023 | IoT-enabled pressure sensors for real-time monitoring. |

| Thermal Performance Testing | Assesses radiator heat transfer efficiency under various operating conditions. | SAE J552 | Data analytics software for performance tracking. |

| Corrosion Resistance Testing | Evaluates the durability of radiator materials against corrosion agents. | ASTM B117 | Automated electrochemical testing systems. |

| Vibration Testing | Checks mechanical strength and stiffness under vibrational loads. | ISO 9001 | Advanced simulation software for stress analysis. |

| Leak Detection Testing | Identifies leaks in radiator systems using various detection methods. | ASTM F1179 | Software tools for leak analysis and reporting. |

In the pursuit of excellence in radiator quality control, benchmarking against industry standards is essential. Effective testing techniques can significantly impact the reliability and performance of radiators. By adhering to rigorous testing protocols, manufacturers can ensure that their products meet the expected thermal efficiency, durability, and overall quality demanded by consumers. Advanced methods such as thermal performance evaluations, fluid leakage tests, and stress simulations can reveal critical insights into a radiator's efficacy.

Recent reviews on cooling solutions emphasize the importance of build quality and thermal benchmarks. For instance, assessments of various liquid coolers highlight the direct correlation between quality control practices and performance metrics. Establishing clear standards for radiator testing can not only streamline the production process but also cultivate consumer trust. Ensuring that every radiator meets these benchmarks ultimately leads to improved market competitiveness and user satisfaction.

In today's rapidly evolving automotive sector, the integration of automation in radiator testing processes is crucial for enhancing efficiency and ensuring product quality. The Asia Pacific automation testing market is projected to experience significant growth, reaching an estimated valuation of USD 42.97 billion by 2033, up from USD 12.20 billion in 2025, highlighting the increasing adoption of automated solutions. This trend underscores the need for manufacturers to improve testing methodologies to maintain high standards in radiator quality control.

The application of advanced testing techniques, coupled with automation, not only accelerates the testing cycle but also enhances accuracy and coverage. Modern test authoring practices have emerged, enabling teams to script and maintain automated tests effectively. As noted by industry experts, optimizing automated tests can lead to a substantial reduction in labor while boosting overall product reliability.

Tips: Consider leveraging AI-powered testing tools to maximize the efficiency of your radiator testing processes. Additionally, ensure that your team is equipped with the latest automation software to stay competitive in a growing market. By focusing on these aspects, organizations can significantly improve their quality assurance practices while keeping pace with industry advancements.

The advancement of predictive analytics is revolutionizing quality management in the radiator manufacturing industry. By leveraging data-driven insights, manufacturers can anticipate potential quality issues and streamline production processes. According to a report by MarketsandMarkets, the global predictive analytics market is projected to grow from $10.95 billion in 2020 to $34.69 billion by 2026, highlighting the increasing adoption of these technologies across various sectors, including automotive.

Through predictive analytics, manufacturers can analyze historical performance data, monitor real-time production metrics, and identify patterns that indicate potential defects. A study by McKinsey indicates that companies employing predictive maintenance can reduce equipment failures by up to 50% and maintenance costs by up to 30%. This transformation not only ensures higher quality radiators but also enhances operational efficiency, reducing downtime and resource waste. Embracing such advanced testing techniques enables organizations to uphold stringent industry standards, ultimately leading to superior product quality and customer satisfaction.