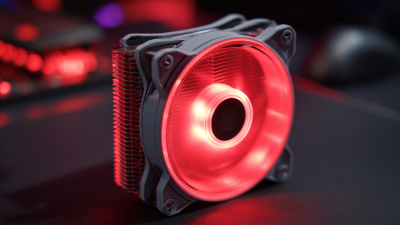

In the competitive landscape of manufacturing, ensuring the highest standards of

Radiator Quality Control is paramount for success.

Radiators play a critical role in various applications, from automotive to industrial systems, thus

necessitating a meticulous approach to their production. This article delineates the top

10 essential tips for manufacturers aiming to enhance their

quality control processes. By following these guidelines, companies can not only improve product reliability

but also reduce costs associated with defects and rework.

Effective Radiator Quality Control involves a combination of rigorous testing, precision engineering, and adherence to industry standards. Manufacturers must stay abreast of the latest technologies and methodologies that can streamline quality checks without compromising on efficiency. From the selection of high-grade materials to the implementation of automated inspection systems, these strategies will empower manufacturers to deliver exceptional radiators consistently. In a market where customer expectations are ever-increasing, implementing robust quality control measures is not just beneficial; it's essential for long-term success and customer satisfaction.

When it comes to ensuring radiator quality control in manufacturing, material selection is a critical factor that can significantly impact performance and longevity. Industry reports reveal that nearly 30% of radiator failures can be traced back to inadequate material properties, which underscores the importance of choosing the right materials. High-quality metals such as aluminum and copper are often favored due to their excellent thermal conductivity and corrosion resistance. According to the latest market analysis, aluminum radiators, recognized for their lightweight and efficiency, account for approximately 65% of the market share, demonstrating a shift towards materials that enhance performance while minimizing weight.

Moreover, manufacturers must consider the compatibility of selected materials with various coolant types and operating environments. A study by the American Society of Mechanical Engineers highlights that improperly chosen materials can result in premature degradation when exposed to specific chemical environments. For instance, copper radiators may be more effective in certain applications but can face issues related to galvanic corrosion when in contact with aluminum parts. Therefore, conducting comprehensive assessments of material properties, corrosion rates, and thermal performance is essential in selecting the right materials that guarantee the radiator's efficacy and durability throughout its lifecycle.

Effective testing procedures are crucial for guaranteeing the quality of radiator components in manufacturing. First and foremost, manufacturers should establish a robust framework for conducting both non-destructive and destructive testing. Non-destructive testing methods, such as ultrasonic inspection and radiographic testing, allow for the identification of internal flaws without damaging the components. By implementing these methods early in the production process, manufacturers can catch defects before they become costly issues later on.

Additionally, incorporating thermal cycling tests can simulate real-world operating conditions to ensure that the radiators perform effectively under various temperature ranges. These tests help identify potential weaknesses in materials or assembly processes, allowing for timely adjustments. Regular quality audits and performance evaluations should also be integrated into the production cycle to maintain high standards. By consistently applying these testing procedures, manufacturers can enhance the reliability and durability of their radiator products, ultimately improving customer satisfaction and reducing return rates.

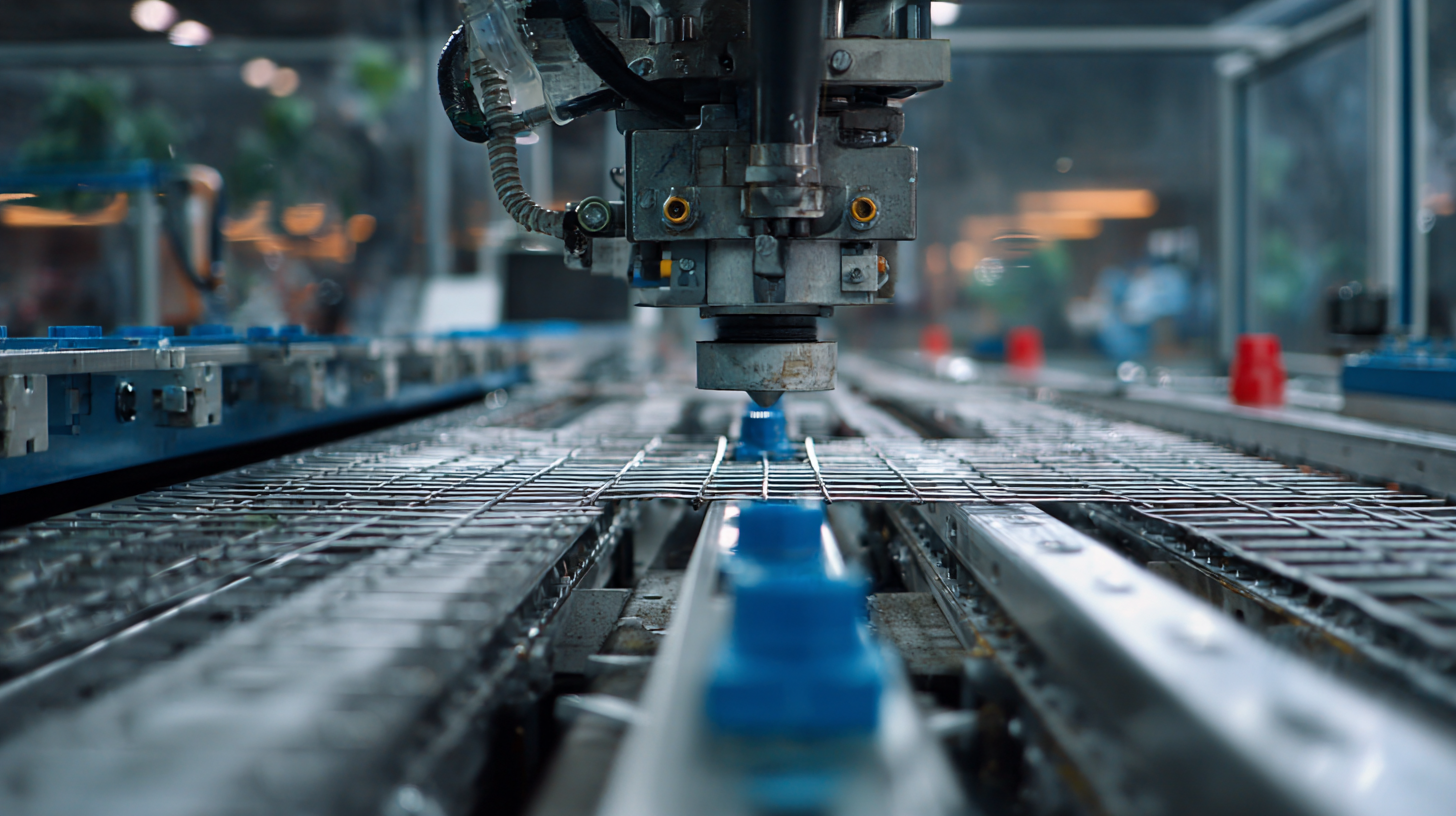

Ensuring quality control in the radiator assembly line is crucial for manufacturers aiming to deliver reliable thermal systems. According to a report by Grand View Research, the global automotive radiator market is expected to reach USD 6.45 billion by 2025, highlighting the importance of quality in this competitive sector.

One of the best practices for maintaining high-quality standards is the implementation of a rigorous inspection process at various stages of production. Regular audits and checks can identify defects early, reducing rework costs and increasing overall efficiency, as highlighted by data from the International Journal of Production Research.

Another essential practice involves the use of advanced technologies such as automation and AI-driven analytics. A study published in the Journal of Manufacturing Science and Engineering noted that integrating machine learning into quality control processes can improve defect detection rates by up to 30%. By leveraging these technologies, manufacturers can minimize human error and ensure the radiators meet the necessary specifications before reaching customers. Additionally, thorough training programs for assembly line workers to recognize flaws can foster a quality-driven culture, ultimately enhancing product durability and reliability.

In the competitive landscape of radiator manufacturing, ensuring high-quality production is paramount. Advanced technology plays a crucial role in achieving real-time quality monitoring, allowing manufacturers to detect issues early in the production process. A report from the International Society of Automation indicates that integrating advanced monitoring systems can reduce defects by up to 30%, significantly enhancing overall product reliability. By harnessing technologies such as IoT sensors and machine learning algorithms, manufacturers can continuously track various parameters such as temperature, pressure, and flow rate during production, ensuring that every component meets stringent quality standards.

In the competitive landscape of radiator manufacturing, ensuring high-quality production is paramount. Advanced technology plays a crucial role in achieving real-time quality monitoring, allowing manufacturers to detect issues early in the production process. A report from the International Society of Automation indicates that integrating advanced monitoring systems can reduce defects by up to 30%, significantly enhancing overall product reliability. By harnessing technologies such as IoT sensors and machine learning algorithms, manufacturers can continuously track various parameters such as temperature, pressure, and flow rate during production, ensuring that every component meets stringent quality standards.

Moreover, real-time data analysis allows for immediate corrective actions, minimizing waste and production downtime. According to a study conducted by the Manufacturing Technology Centre, organizations that implemented smart quality control systems saw a reduction in quality-related costs by approximately 25%. This shift not only optimizes resource utilization but also boosts customer satisfaction due to the higher consistency in product quality. As the industry moves towards more automated and data-driven approaches, investing in advanced technology for quality monitoring becomes not just beneficial but essential for maintaining a competitive edge in the radiator manufacturing sector.

In the competitive landscape of radiator manufacturing, continuous improvement strategies are crucial for maintaining high standards of quality control. With advancements in technology, manufacturers can leverage deep learning methods for detecting faults in components such as gaskets, ensuring that every product meets stringent quality requirements.

Automating these inspections not only increases efficiency but also enhances the accuracy of fault detection, allowing teams to focus on more complex quality issues.

Automating these inspections not only increases efficiency but also enhances the accuracy of fault detection, allowing teams to focus on more complex quality issues.

To further strengthen quality control processes, manufacturers should consider implementing the following essential tips.