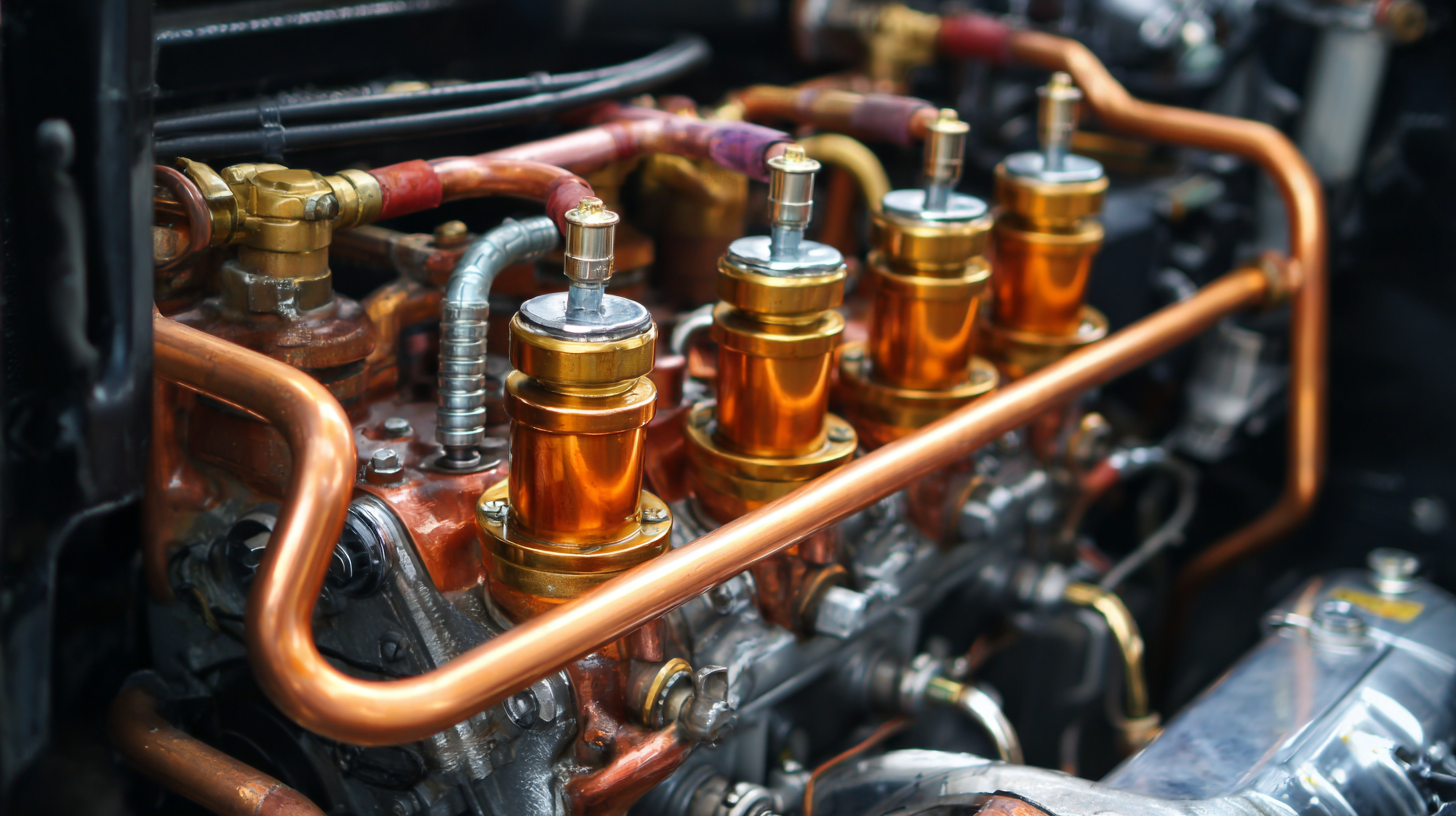

In the realm of automotive engineering, the significance of efficient heat dissipation cannot be overstated, especially when it comes to enhancing vehicle performance. The Copper Engine Radiator has emerged as a critical component in this process due to its superior thermal conductivity compared to aluminum counterparts. According to a report by the Society of Automotive Engineers (SAE), vehicles equipped with copper radiators can achieve a cooling efficiency improvement of up to 25%, enabling engines to maintain optimal operating temperatures even under heavy loads. This efficiency translates to not only enhanced performance but also increased longevity of engine components.

With the global automotive industry increasingly emphasizing sustainability and performance, leveraging the advantages of Copper Engine Radiators is essential for manufacturers aiming to meet the stringent demands of modern consumers. As advancements continue in radiator technology, the role of copper in thermal management is set to become even more pivotal.

Copper engine radiators have gained recognition for their exceptional heat transfer efficiency, playing a crucial role in enhancing vehicle performance. According to a report by the Society of Automotive Engineers, copper radiators can improve heat transfer rates by up to 30% compared to traditional aluminum radiators. This increased efficiency allows for better regulation of engine temperatures, which is especially important in high-performance vehicles where optimal engine function is critical.

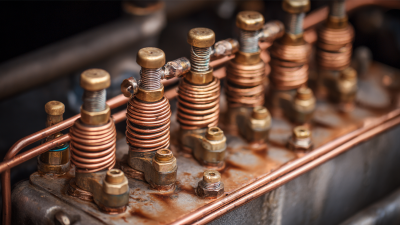

The superior thermal conductivity of copper, approximately 401 W/mK, significantly outperforms aluminum’s thermal conductivity of around 205 W/mK. This means that copper radiators can dissipate heat more effectively, leading to decreased engine temperatures and improved overall performance. A study published in the International Journal of Heat and Mass Transfer highlights that with efficient heat dissipation, engines can maintain optimal operating conditions, resulting in better fuel efficiency and reduced emissions. In high-stress situations, such as racing or heavy towing, the advantages of using copper radiators become even more pronounced, as they ensure that the engine remains cool and performs reliably under extreme conditions.

When it comes to enhancing vehicle performance, the choice of materials in engine radiators plays a crucial role.

Copper, known for its superior thermal conductivity, provides significant advantages over traditional aluminum materials.

As automotive technologies evolve, the emphasis on efficient heat dissipation has led to increased adoption of copper engine radiators, which can reduce engine temperature more effectively, thus improving overall vehicle efficiency and longevity.

According to industry reports, copper's thermal conductivity can reach up to 400 W/m·K, significantly outperforming that of aluminum, which hovers around 237 W/m·K.

Moreover, recent advancements in materials science, such as the development of nanometer-scale copper paste, have further expanded the applications of copper in automotive sectors.

Innovations in copper-based technologies not only support heat dissipation requirements but also enhance the safety and reliability of electric vehicle batteries.

For instance, in water-based zinc-manganese copper batteries, the unique electrochemical behavior of copper is being explored, demonstrating promising increases in energy density and cycle life.

As recorded by various market analyses, the composite copper foil industry is witnessing rapid growth, driven by a demand for lightweight and cost-effective solutions in next-generation lithium battery applications.

This trend underscores the ongoing shift toward high-performance copper solutions in the automotive landscape.

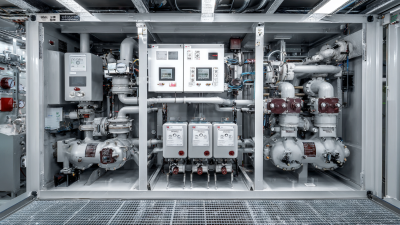

To ensure optimal radiator performance in vehicles, regular maintenance is crucial. According to a report by the Society of Automotive Engineers, about 30% of vehicles experience performance issues due to inadequate cooling system maintenance. Essential tasks include:

Over time, corrosion can occur in copper radiators, leading to reduced efficiency. Using corrosion inhibitors in your coolant can significantly prolong the lifespan of the radiator, keeping it functioning efficiently.

Moreover, flushing the cooling system every couple of years is recommended to remove accumulated deposits and ensure effective heat dissipation. A study by the International Journal of Automotive Engineering highlighted that neglected cooling systems could increase engine temperatures by 15% or more, leading to reduced engine performance and potential damage.

By adhering to these maintenance tips, vehicle owners can not only enhance the performance of copper radiators but also improve overall engine efficiency, ensuring a smoother and more powerful driving experience.

Innovative designs in copper engine radiators can significantly enhance vehicle performance by improving airflow and optimizing heat dissipation. Unlike traditional materials, copper has superior thermal conductivity, allowing for quicker heat transfer from the engine to the surrounding air. This property is further amplified through innovative radiator designs that incorporate larger fin areas and strategically placed air inlets. These modifications facilitate a more efficient passage of air, minimizing the temperature of the coolant and, in turn, preventing overheating during high-performance scenarios.

Moreover, the integration of advanced aerodynamic principles in radiator design can lead to reduced drag and increased efficiency. For example, some manufacturers are utilizing curved fins and tapered shapes to encourage smoother airflow. This reduces turbulent air pockets that can hinder cooling capabilities. By enhancing the interaction between the radiator and the ambient air, vehicles can maintain optimal operating temperatures even under demanding conditions, ensuring peak engine performance. These innovations not only extend the lifespan of vehicle components but also contribute to improved fuel efficiency, making them an indispensable aspect of modern automotive engineering.

Thermodynamics plays a pivotal role in the performance of vehicle engines, especially when it comes to managing engine temperatures effectively. A vehicle's engine generates a considerable amount of heat during operation, and if this heat is not efficiently dissipated, it can lead to performance issues, reduced engine life, or even catastrophic failure. By employing materials with excellent thermal conductivity, such as copper, manufacturers can create radiators that enhance heat dissipation, ultimately improving engine efficiency and performance.

**Tips for Enhancing Heat Dissipation:**

1. Ensure regular maintenance of your cooling system, including flushing and refilling coolant, to prevent overheating and improve thermal efficiency.

2. Consider upgrading to copper engine radiators, as they provide superior heat transfer capabilities compared to traditional aluminum radiators.

3. Monitor engine temperature regularly with an accurate gauge to identify any irregularities early, allowing for timely interventions.

Incorporating advanced thermodynamic principles into vehicle design is essential for optimizing engine performance. Utilizing copper radiators not only boosts heat dissipation capabilities but also contributes to a more stable operating temperature, enhancing overall efficiency. The synergy between thermodynamics and material science thus plays a crucial role in elevating the performance standards of modern engines.

| Parameter | Copper Radiator | Aluminum Radiator | Impact on Engine Performance |

|---|---|---|---|

| Thermal Conductivity (W/m·K) | 385 | 237 | Improved heat dissipation, optimal operating temperature |

| Weight (kg) | 15 | 10 | Slightly heavier but better performance |

| Corrosion Resistance | Moderate | High | Longer lifespan with aluminum |

| Cost ($) | 150 | 100 | Higher initial investment for copper |

| Heat Dissipation Efficiency (%) | 95 | 85 | Enhances vehicle performance through better cooling |