In the realm of automotive maintenance, ensuring the longevity of your radiator is crucial for optimal vehicle performance. One of the primary threats to a radiator's lifespan is corrosion, which can lead to leaks, inefficiencies, and costly repairs. To combat this, implementing effective corrosion resistance techniques is essential. This guide delves into various methods to enhance radiator longevity through improved Radiator Corrosion Resistance. From the selection of high-quality materials to the application of protective coatings, the strategies discussed will empower vehicle owners to safeguard their radiators against corrosive elements and prolong their functionality. By understanding the underlying causes of corrosion and actively employing preventative measures, car enthusiasts and everyday drivers alike can maintain their vehicles in peak condition while minimizing maintenance costs.

Corrosion is a primary factor that significantly impacts the lifespan of radiators, with studies indicating that up to 30% of all mechanical failures in automotive systems can be traced back to corrosion-related issues. The presence of moisture and contaminants in the coolant can lead to pitting and rust formation on metal surfaces, causing leaks and ultimately leading to radiator failure. According to the National Association of Corrosion Engineers (NACE), the annual cost of corrosion-related maintenance and replacement in various industries amounts to approximately $276 billion in the United States alone, highlighting the importance of effective corrosion management strategies.

To enhance radiator longevity, it is crucial to implement corrosion resistance techniques such as using corrosion inhibitors in the coolant, selecting materials with intrinsic resistance to corrosion, and ensuring regular maintenance checks. For instance, a 2019 report from the Society of Automotive Engineers (SAE) emphasized that the use of modern aluminum alloys, combined with proper coolant formulations, can extend the operational life of radiators by up to 40%. Moreover, adopting practices such as periodic flushing of the cooling system and checking the pH levels of the coolant can prevent corrosion build-up, thereby maximizing radiator efficiency and performance over time.

Choosing the right materials is crucial for enhancing the longevity of radiators, particularly when it comes to corrosion resistance. According to a report by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), improper material selection can lead to a reduction in the lifespan of radiators by 20-30%. This highlights the importance of opting for materials that inherently resist corrosion, such as stainless steel and aluminum alloys, known for their excellent durability and long-term performance in harsh conditions.

Furthermore, specific coatings and treatments can significantly enhance the corrosion resistance of standard materials. A study published in the Corrosion Science journal indicated that applying a corrosion-resistant coating can increase the service life of radiators by up to 50%. This is particularly relevant in environments where coolant systems are exposed to a variety of corrosive substances. By prioritizing the right materials and protective measures, manufacturers can ensure that their radiators not only perform efficiently but also remain functional for an extended period, ultimately benefiting both the environment and maintenance costs.

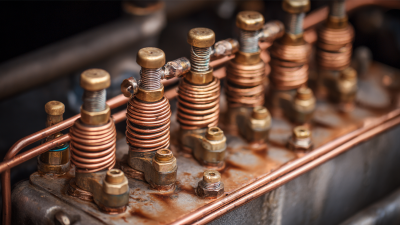

Protective coatings and treatments play a crucial role in enhancing the longevity of radiators by providing an effective barrier against corrosion. The application of specialized coatings, such as epoxy, polyurethane, or zinc-rich primers, can significantly reduce the impact of corrosive elements that radiators encounter, such as moisture and chemicals in the environment. These coatings not only shield the metal from direct exposure but also facilitate easy cleaning, which helps maintain radiator efficiency and appearance over time.

In addition to traditional coatings, advanced treatments like anodizing and galvanizing offer additional corrosion resistance. Anodizing transforms the surface of aluminum radiators, creating a tough, protective oxide layer that improves durability. On the other hand, galvanizing involves coating steel radiators with a layer of zinc, which acts as a sacrificial metal, preventing rust formation. By implementing these protective measures, radiator manufacturers and users can ensure a prolonged lifespan, ultimately resulting in cost savings and reduced environmental impact through less frequent replacements and repairs.

| Technique | Description | Advantages | Typical Lifespan Improvement |

|---|---|---|---|

| Zinc Coating | A protective layer of zinc that protects metal from moisture and corrosion. | Highly effective corrosion protection, long-lasting | Up to 15 years |

| Epoxy Coatings | A two-part coating that hardens to form a durable barrier against corrosion. | Excellent adhesion, impact resistance, and chemical resistance | 10 to 20 years |

| Powder Coating | A dry finishing process that applies a protective layer to metal surfaces. | Smooth finish, variety of colors, and strong corrosion resistance | Up to 20 years |

| Cathodic Protection | An electrochemical process that prevents corrosion by making the metal the cathode of an electrochemical cell. | Effective in harsh environments, long-term protection | Indefinite lifespan with proper maintenance |

| Corrosion Inhibitors | Chemical additives that decrease the corrosion rate of metals. | Ease of application, cost-effective | 3 to 5 years |

Regular maintenance practices are crucial for enhancing radiator longevity and preventing corrosion damage. One effective strategy involves routine inspections to identify early signs of corrosion, such as rust formation or leaks. Establishing a regular cleaning schedule can help remove contaminants that may accelerate corrosion. Additionally, utilizing protective coatings and treatments can significantly improve the resistance of radiators against corrosive effects.

Recent developments in corrosion inhibition have highlighted the promising role of phytochemicals derived from plants. These natural agents have demonstrated the ability to inhibit corrosion in mild steel and aluminum, offering a sustainable alternative to traditional chemical inhibitors. Furthermore, understanding the mechanisms behind corrosion processes, such as those associated with carbon dioxide in various environments, allows for the implementation of targeted anti-corrosion measures. Combining these innovative approaches with established best practices is essential for effective corrosion management in radiators, ultimately extending their operational lifespan and ensuring reliable performance.

Innovative technologies play a crucial role in enhancing radiator durability against corrosion, a common issue that can significantly affect the performance and lifespan of radiators. Among the most promising advancements is the implementation of advanced coatings that provide a protective barrier against corrosive elements. These coatings, such as ceramic and epoxy-based solutions, not only resist chemical degradation but also bolster the radiator’s surface, minimizing wear from environmental factors.

Another key innovation is the use of corrosion-resistant materials, such as aluminum alloys and stainless steel, which inherently possess better resistance to rust and corrosion compared to traditional materials. Additionally, incorporating sacrificial anodes in the design offers a proactive approach by directing corrosion away from critical components, thereby extending the overall life of the radiator. Emphasizing these technologies not only enhances radiator performance but also mitigates the costs associated with repairs and replacements, leading to more efficient and reliable automotive systems.