In the realm of automotive maintenance and performance, ensuring optimal Radiator Corrosion Resistance is crucial for the longevity and efficiency of your vehicle's cooling system. Corrosion can rapidly lead to coolant leaks, reduced heat exchange effectiveness, and ultimately costly repairs. To combat these issues, it is essential to adopt proactive measures that enhance the durability of your radiator.

This article presents seven effective tips that not only highlight the importance of maintaining high levels of corrosion resistance but also provide practical strategies for vehicle owners to implement. By understanding the common causes of radiator corrosion and utilizing these best practices, you can protect your investment and ensure your vehicle operates at its best, even under challenging conditions.

Embrace these proven techniques to boost your radiator's resilience and shield it from the elements that threaten its performance.

Radiator corrosion is a prevalent issue that can significantly affect the lifespan and efficiency of a vehicle's cooling system. The primary causes of corrosion include the chemical reactions between the metal components and the coolant, which can lead to the formation of rust and scale. Factors such as water quality, temperature fluctuations, and the presence of impurities within the coolant can accelerate these processes, resulting in leaks and decreased heat transfer efficiency.

The effects of radiator corrosion are both immediate and long-term. In the short term, drivers may experience overheating, increased repairs, and coolant leaks. Over time, prolonged corrosion can lead to severe engine damage and costly replacement procedures. Therefore, understanding these causes and their impacts is crucial for vehicle maintenance. Implementing strategies to enhance corrosion resistance can help mitigate these issues and ensure a reliable and efficient cooling system. Regular checking and maintaining the coolant's pH level, using corrosion inhibitors, and ensuring proper flushing of the radiator can significantly contribute to minimizing corrosion risks.

| Tip | Description | Effectiveness | Implementation Difficulty |

|---|---|---|---|

| Regular Maintenance | Routine inspections and flushing to remove contaminants. | High | Easy |

| Use Corrosion Inhibitors | Additives that prevent corrosion in coolant systems. | Very High | Moderate |

| Ensure Proper Coolant Levels | Maintain correct levels to ensure effective heat transfer. | High | Easy |

| Avoid Mixing Coolants | Different coolants can react adversely and increase corrosion. | High | Easy |

| Install a Radiator Cap | Prevents excess pressure that can lead to leaks and corrosion. | Moderate | Easy |

| Monitor pH Levels | Ensure coolant pH is within optimal range to minimize corrosion. | Very High | Moderate |

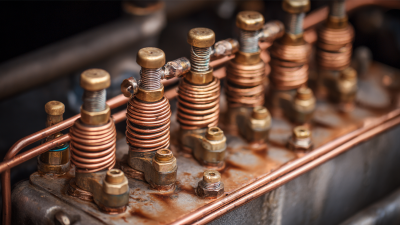

| Choose Quality Materials | Select radiators made from corrosion-resistant materials. | High | Moderate |

When it comes to enhancing radiator corrosion resistance, selecting the right materials plays a crucial role. According to a report by the Corrosion Control Journal, appropriate material selection can reduce corrosion-related failures by up to 70%. Materials such as aluminum and specific stainless steels are often favored due to their inherent resistance to corrosive environments. For example, aluminum radiators, which are widely used in modern vehicles, offer a lightweight solution combined with excellent corrosion resistance due to their natural oxide layer that forms when exposed to air.

Furthermore, the application of corrosion-resistant coatings is another method to significantly improve radiator longevity. The American Society of Mechanical Engineers (ASME) suggests that using epoxy or polyurethane coatings can lead to a 50% increase in the service life of radiators in harsh operating conditions. This is particularly vital in systems where radiators handle coolants containing aggressive additives. By prioritizing the selection of materials and coatings, manufacturers can effectively minimize corrosion risks and improve overall efficiency in radiator performance.

Preventive maintenance is crucial for extending the lifespan of your radiator and enhancing its corrosion resistance. Regularly scheduled inspections can identify potential issues before they escalate, allowing for timely interventions. This includes checking for signs of leaks, corrosion, and debris buildup. By keeping the radiator clean and well-maintained, you significantly reduce the chances of rust formation and other damaging factors that can compromise its efficiency.

Additionally, proper fluid management plays a vital role in radiator maintenance. Using high-quality coolant with anti-corrosive properties helps in protecting the internal surfaces of the radiator from oxidation. It's also important to regularly flush the coolant system to remove any accumulated contaminants that can cause corrosion over time. Adjusting the pH level of the coolant to an optimal range can further enhance its protective capabilities, ensuring that the radiator remains in peak condition for years to come.

Protective coatings play a crucial role in enhancing the durability and corrosion resistance of radiators, which are vital components in various industrial and automotive applications. According to a report from the National Association of Corrosion Engineers (NACE), corrosion damage in industrial facilities can lead to economic losses upwards of $276 billion annually in the United States alone. This underscores the importance of implementing effective protective strategies, including advanced coating technologies, to prolong the lifespan of radiators.

When applying protective coatings, it is essential to consider factors such as adhesion strength, thermal resistance, and chemical compatibility. Studies have shown that epoxy-based coatings can significantly improve corrosion resistance due to their exceptional bonding properties and impermeability. A report published in the Journal of Coatings Technology found that radiators treated with a high-performance epoxy coating demonstrated a corrosion rate reduction of over 80% compared to untreated surfaces. Additionally, the use of nanotechnology in coatings has emerged as a promising avenue, offering superior barrier properties that further enhance performance against harsh environmental conditions. This innovation not only extends the life of radiators but also ensures optimal efficiency in operation, ultimately contributing to more sustainable industrial practices.

Regular monitoring and inspection techniques are essential for maintaining radiator health and enhancing corrosion resistance. Implementing advanced inspection methods can lead to the early detection of potential issues, ensuring radiators function efficiently and remain durable over time. Techniques such as visual assessments and thermal imaging can identify leaks and hot spots, preventing further deterioration and costly repairs.

Incorporating technologies like deep learning and smart pigging for diagnostic purposes can revolutionize radiator maintenance. Automated detection systems can quickly analyze conditions to identify faults such as corrosion or misalignment, similar to the innovations seen in gasket inspection. These methods not only improve the accuracy of inspections but also optimize overall maintenance strategies. By adopting such techniques, businesses can significantly enhance the longevity and reliability of their radiator systems while minimizing downtime.