The "Copper Engine Radiator" has long been a fundamental component of vehicle cooling systems, playing a vital role in maintaining optimal engine performance. According to a report by the Society of Automotive Engineers, over 90% of vehicles on the road utilize some form of radiator technology to ensure proper thermal management. The choice of materials used in radiators significantly impacts both efficiency and durability, with copper being a traditional favorite due to its excellent thermal conductivity and resistance to corrosion.

As automotive technology continues to evolve, copper engine radiators remain relevant, adapting to advancements in engine performance and environmental standards. Recent studies indicate that copper radiators can improve heat transfer by as much as 30% compared to aluminum counterparts, making them an attractive option for performance-oriented vehicles. This introduction of efficiency not only aids in fuel economy but also contributes to reducing greenhouse gas emissions, aligning with the industry's push towards more sustainable practices. Understanding the mechanics and advantages of copper engine radiators is essential for both automotive professionals and enthusiasts alike, as they continue to be a vital link in the chain of automotive innovation.

A copper engine radiator is a critical component of a vehicle's cooling system, designed to dissipate heat generated by the engine during operation. Made primarily from copper due to its excellent thermal conductivity, copper radiators facilitate efficient heat exchange, allowing the engine to maintain optimal operating temperatures. This is vital because overheating can lead to engine damage and decreased performance. According to industry data, copper radiators exhibit a thermal efficiency improvement of about 20% compared to their aluminum counterparts, making them a preferred choice in various high-performance applications.

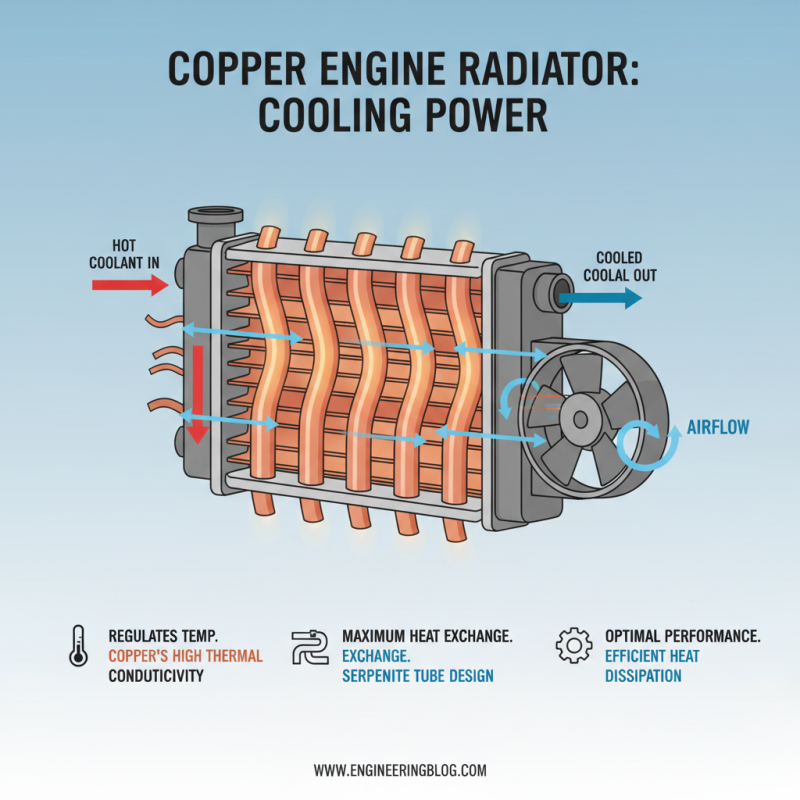

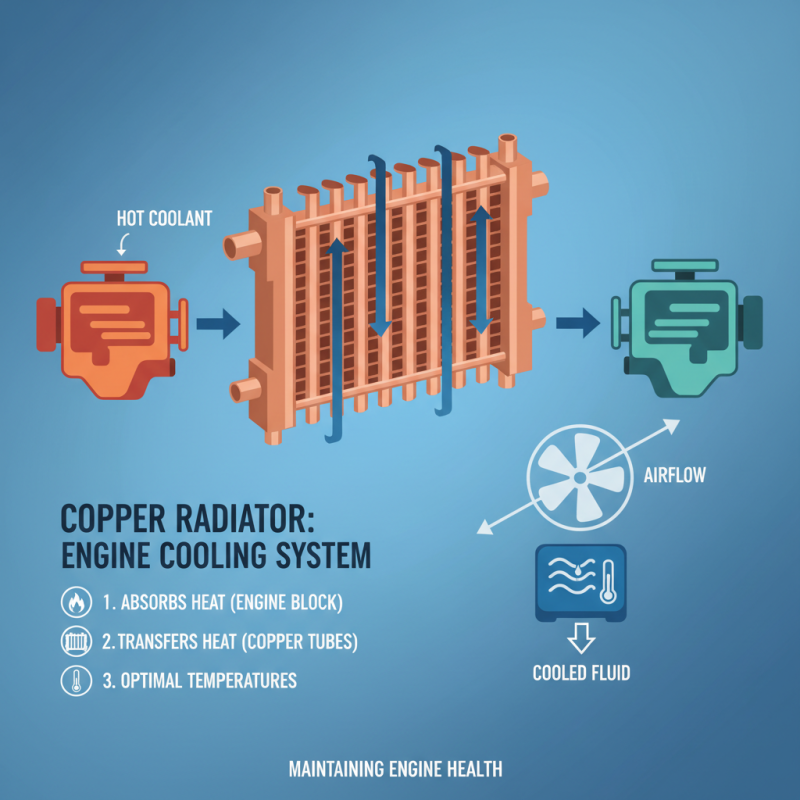

The operation of a copper engine radiator is straightforward yet effective. Engine coolant circulates through the radiator, where it releases heat into the ambient air. When the vehicle is in motion, air flows through the radiator's fins, enhancing the cooling process. The copper tubes and fins are designed for maximum surface area contact, ensuring that heat transfer occurs rapidly. Research indicates that a well-maintained radiator can improve engine cooling efficiency, prolong engine life, and enhance overall vehicle performance.

Regular servicing, including flushing and cleaning, is recommended to keep the radiator operating at peak efficiency, as corrosion and debris buildup can significantly hinder its performance.

The key components of a copper engine radiator play a crucial role in maintaining engine temperature and ensuring optimal performance. At the heart of the radiator are the copper tubes, which are designed to efficiently transfer heat away from the engine coolant. These tubes are typically arranged in a serpentine layout to maximize surface area and promote effective heat exchange with the surrounding air. The copper material is favored for its excellent thermal conductivity, allowing for rapid cooling of the hot coolant that flows through them.

In addition to the tubes, the radiator also consists of fins, which are thin metal sheets that increase the area for heat dissipation. These fins enhance airflow around the tubes, facilitating a more efficient cooling process. When air passes through the radiator, it absorbs heat from the coolant running through the copper tubes, thereby lowering the temperature of the engine. Another vital component is the header tanks, which are located at either end of the radiator. These tanks help to manage the coolant flow and ensure even distribution, playing a pivotal role in the radiator’s overall efficiency.

Together, these components form an integrated system that keeps your vehicle's engine running at the optimal temperature. The combination of copper tubes, fins, and header tanks work in unison to dissipate heat, contributing to the longevity and reliability of the engine. Proper maintenance of the radiator and its components is essential to prevent overheating and ensure that the vehicle operates smoothly.

A copper engine radiator plays a crucial role in maintaining optimal operating temperatures in a vehicle. At its core, it functions by transferring heat away from the engine coolant, which absorbs heat generated during combustion. As the engine operates, the coolant circulates through the engine block and absorbs excess heat, ensuring that the engine does not overheat. This hot coolant then travels to the radiator, where it passes through a series of thin copper tubes.

The radiator utilizes airflow to dissipate heat from the coolant effectively. As the vehicle moves, air flows through the radiator's grille and over the external fins attached to the tubes. This airflow cools the hot coolant as it moves through the radiator, allowing it to lower its temperature before returning to the engine. The cooled coolant is then pumped back into the engine, where it will continue to absorb heat, creating a continuous cycle that prevents overheating. This efficient heat exchange process is essential for the longevity and performance of any vehicle, highlighting the importance of the copper engine radiator in vehicle cooling systems.

Copper radiators have long been regarded as a superior choice for vehicle cooling systems due to their excellent thermal conductivity and durability. One of the primary advantages of using copper over other materials, such as aluminum, is its ability to dissipate heat more effectively. This property allows for quicker cooling of the engine, helping to maintain optimal operating temperatures and enhance overall engine performance. Additionally, copper's natural corrosion resistance enhances the longevity of the radiator, reducing the need for frequent replacements and repairs.

Another significant benefit of copper radiators is their superior strength. Copper is less prone to deformation under high pressure or extreme heat, making it a reliable option for high-performance vehicles and engines. Furthermore, copper components are relatively easy to repair, as they can be soldered back together with relative ease compared to aluminum. This maintenance advantage can save vehicle owners both time and money in the long run, reaffirming copper's status as an ideal choice for automotive cooling systems.

| Feature | Copper Radiators | Aluminum Radiators | Plastic Radiators |

|---|---|---|---|

| Heat Transfer Efficiency | Excellent | Good | Fair |

| Durability | High | Moderate | Low |

| Weight | Heavier | Lighter | Lightest |

| Repairability | Easy | Moderate | Difficult |

| Cost | Moderate | Low | Very Low |

Copper engine radiators are renowned for their efficiency in cooling engine temperatures, but maintaining them is crucial for optimal vehicle performance. Regular maintenance significantly extends the lifespan of these radiators and ensures they function effectively. One of the most important tips is to routinely check for any signs of corrosion or leaks. Copper is prone to oxidation, which can lead to pinhole leaks over time. If detected early, these issues can often be repaired rather than requiring a full replacement.

Another key maintenance practice is to ensure that the coolant levels are adequate. Insufficient coolant can cause the radiator to overheat, while using the correct coolant mixture reduces the risk of corrosion and improves heat transfer. Flushing the radiator periodically is also essential. This process removes any accumulated debris and sludge, helping to maintain efficient cooling performance. Lastly, consider inspecting the radiator's fins and checking for blockages that might hinder airflow, as reduced airflow can impair cooling efficiency and lead to engine overheating.

This chart illustrates the cooling efficiency of different types of engine radiators, highlighting that copper radiators tend to provide better efficiency compared to aluminum and plastic alternatives.