In the realm of industrial machinery, the significance of selecting the appropriate Compressors Cooler cannot be overstated. An expert in the field, Dr. Emily Hart, emphasizes, "The efficiency and longevity of any cooling system begin with the right compressor cooler selection." This insight underlines the critical role that Compressors Coolers play in enhancing the performance and reliability of various operations.

A well-chosen Compressors Cooler not only aids in maintaining optimal temperatures but also contributes to the overall energy efficiency of the machinery involved. With increasing demands for both performance and sustainability in industrial environments, the choice of cooling equipment has become a pivotal aspect of operational strategy. Ensuring that the right specifications, compatibility, and durability are met can significantly prevent costly downtimes and maximize the output of systems reliant on compressed air and refrigeration.

Ultimately, the right Compressors Cooler serves as a backbone for maintaining operational excellence. As industries evolve and push the boundaries of technology, understanding the nuances of these cooling systems stands paramount. By prioritizing the selection of quality Compressors Coolers, businesses can achieve improved performance, reliability, and efficiency in their operations, paving the way for future advancements.

Compressors coolers play a crucial role across various applications, ensuring that machinery operates within optimal temperature ranges. In industrial settings, for instance, compressor coolers are vital in maintaining the efficiency of refrigeration systems, air conditioning units, and even manufacturing processes where heat generation is inevitable. By effectively dissipating heat produced during operation, these coolers help prevent equipment overheating, which can lead to increased wear and tear, reduced efficiency, and even unexpected breakdowns.

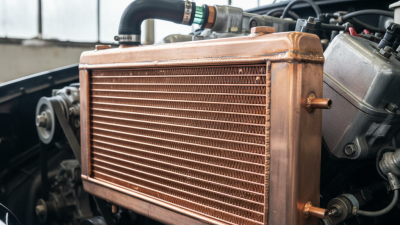

In the automotive sector, compressors coolers contribute significantly to engine performance and longevity. They manage the heat generated by turbochargers and superchargers, allowing for better airflow and fuel efficiency. Moreover, in HVAC systems, proper cooling is essential for regulating indoor climates, ensuring comfort while optimizing energy consumption. Thus, selecting the right compressor cooler tailored to specific operational needs not only enhances performance but also extends the lifespan of the equipment, making it a critical consideration in any application.

When selecting compressors coolers, several critical factors need to be considered to ensure optimal performance and efficiency. One primary consideration is the cooling capacity, which should align with the specific needs of the application. According to industry reports, selecting a cooler with inadequate capacity can lead to overheating, increased energy consumption, and potential equipment failure. For instance, operational studies reveal that a cooler should ideally maintain temperature differentials of 10-15 degrees Fahrenheit below the environment for effective heat exchange.

Another vital factor is the compressor type and its compatibility with the cooler. The right combination can significantly enhance overall system efficiency. Research indicates that rotary screw compressors tend to be more efficient for continuous operations, while reciprocating compressors can be preferable for variable loads. This relationship not only affects the performance but also influences maintenance schedules and operational costs. Additionally, factors such as noise levels, energy efficiency ratings, and environmental impact should also be evaluated based on industry benchmarks, which recommend monitoring systems that achieve at least a 20% improvement in energy efficiency over older models. Adopting these criteria ensures that businesses optimize their production processes while maintaining sustainability and cost-effectiveness.

Compressors coolers play a critical role in various applications, and understanding the different types available can significantly enhance operational efficiency. One of the predominant types is the reciprocating compressor cooler, which is widely used for its reliability and high-pressure capabilities. These coolers are perfect for industries that require precise temperature control, such as refrigeration and air conditioning. They function by compressing the refrigerant, which then dissipates heat effectively, making them suitable for environments with fluctuating temperature demands.

Another essential category is the rotary screw compressor cooler, favored for its continuous operation and energy efficiency. Ideal for large-scale operations, these coolers are designed to handle higher volumes of air and are commonly utilized in manufacturing and industrial settings. Their smooth operation and reduced maintenance requirements make them a cost-effective solution while ensuring a steady temperature. Choosing the right type of compressor cooler based on specific operational needs is vital for achieving optimal performance and maximizing equipment lifespan.

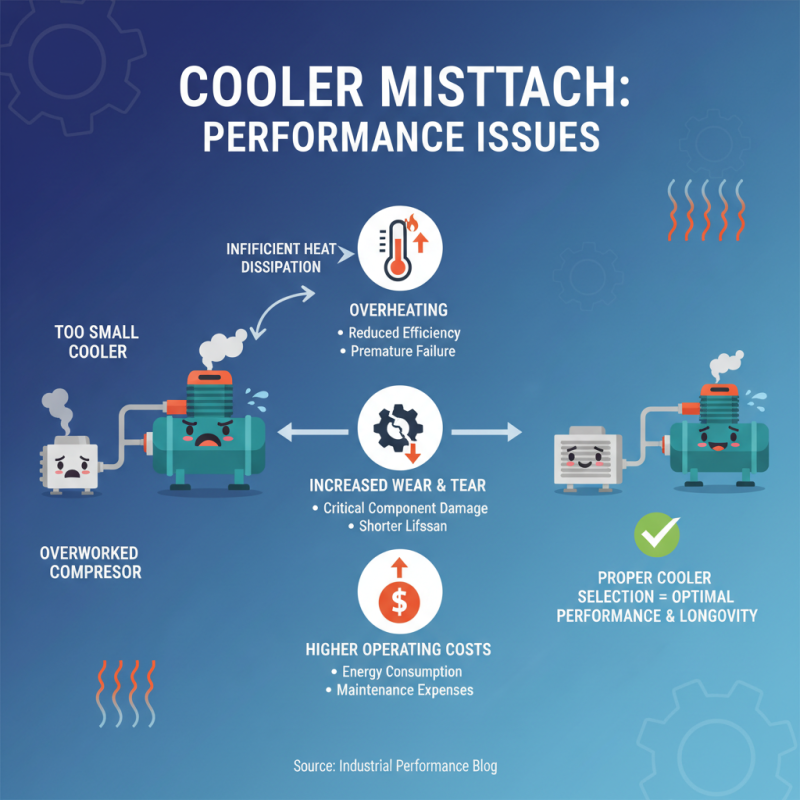

Improper cooler selection can lead to significant performance issues in various applications, primarily due to mismatched cooling capacities. When a cooler is not adequately sized for the compressor it serves, the system may experience overheating, which can reduce efficiency and lead to premature failure. An underperforming cooler may not dissipate heat effectively, causing the compressor to work harder, thus exacerbating wear and tear on critical components. This imbalance can result in increased energy consumption and operating costs, ultimately undermining the intended benefits of the system.

Moreover, the choice of materials and design of the cooler plays a crucial role in its effectiveness. If a cooler is made from subpar materials or poorly designed for specific operating conditions, it may not withstand the temperature fluctuations and pressures of the system. This can lead to leaks, corrosion, and other failures that compromise the overall performance of the compressor. Thus, taking the time to select the appropriate cooler not only ensures optimal operation but also prolongs the lifespan of the compressor and the entire system, preventing costly downtime and repairs.

Proper maintenance of compressor coolers is crucial for ensuring optimal efficiency and longevity. Regularly checking the coolant levels is a good starting point; low coolant can lead to overheating and increase the risk of component failure. Additionally, inspecting and replacing air filters as needed can significantly improve airflow, which is vital for maintaining the correct operating temperature. Clogged filters can restrict airflow and force the compressor to work harder, leading to diminished performance and potential damage over time.

Another important tip for maintaining compressor coolers is to keep the surrounding area clean and free from debris. Accumulation of dirt and dust around the compressor can obstruct airflow and cause overheating. Ensuring that the cooler units are kept clean not only enhances performance but also helps in identifying any potential issues early on. Regularly scheduled professional servicing can further ensure all components are functioning smoothly and are free from wear and tear, which is essential for the reliability and efficiency of the cooling system. By staying proactive with these maintenance strategies, users can safeguard their compressor coolers and optimize their performance.

This bar chart displays the performance efficiency metrics of various compressor coolers based on key factors such as Energy Consumption, Cooling Capacity, Noise Level, and Maintenance Frequency. Maintaining optimal performance in compressor coolers is essential for their efficiency.