As technology continues to advance at a rapid pace, the need for effective thermal management solutions has become increasingly critical. In 2025, the landscape for choosing a Thermal Management Cooler is set to evolve, driven by innovations in materials, design, and application requirements. This evolution demands careful consideration from users looking to optimize the performance and longevity of their electronic devices. Selecting the right cooler is not just about keeping temperatures in check; it is about enhancing overall efficiency and reliability in various environments, from consumer electronics to industrial machinery.

When faced with a plethora of options available in the market, understanding the key features and specifications of Thermal Management Coolers is paramount. Users must evaluate factors such as cooling capacity, airflow design, noise levels, and compatibility with existing systems. Additionally, the growing emphasis on energy efficiency and sustainability means that the best coolers will also be those that minimize environmental impact while delivering superior performance. By taking the time to analyze individual needs and the latest technological advancements, users can make informed decisions that align with their requirements for thermal management in an ever-changing landscape.

Thermal management is a critical component in various industries, particularly in electronics, automotive, and aerospace sectors. As technology continues to evolve, the ability to effectively control heat in devices and systems is paramount to ensure their reliability and performance. According to a report by MarketsandMarkets, the global thermal management market is projected to reach USD 14.3 billion by 2025, reflecting a compound annual growth rate (CAGR) of 9.1% from 2020. This growth underscores the increasing importance of thermal management solutions in maintaining optimal operational conditions and preventing thermal failures.

The principles of thermal management revolve around heat generation, dissipation, and transfer. Understanding these principles is essential for selecting effective cooling solutions tailored to specific needs. For instance, in electronic devices, excessive heat can lead to reduced performance and lifespan. Data from the International Electrotechnical Commission indicates that 50% of electronic failures can be attributed to thermal issues. Thus, implementing robust thermal management strategies not only enhances performance but also prolongs device life, significantly reducing downtime and maintenance costs in the long run.

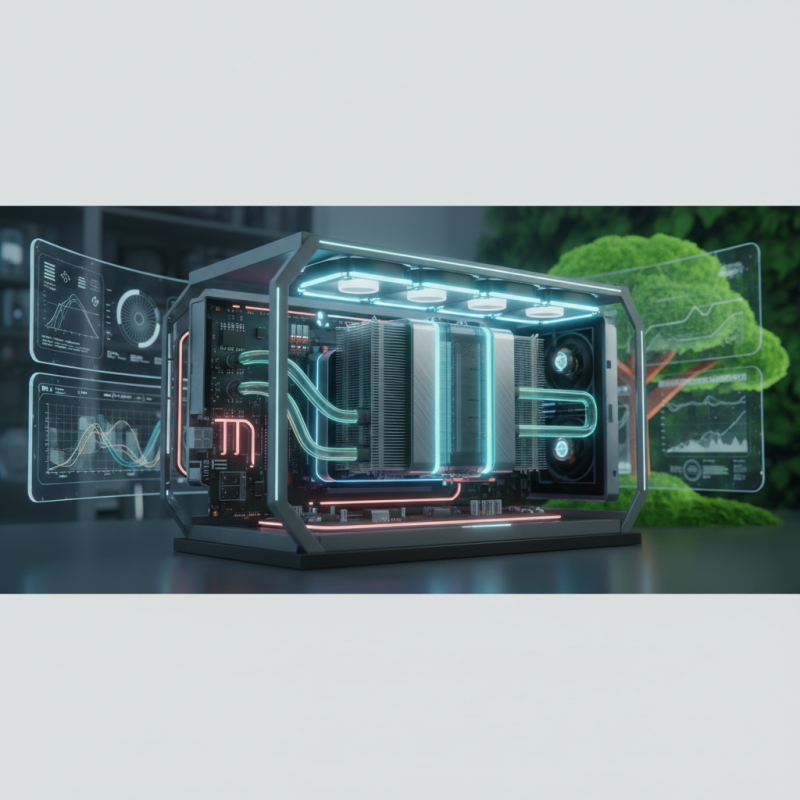

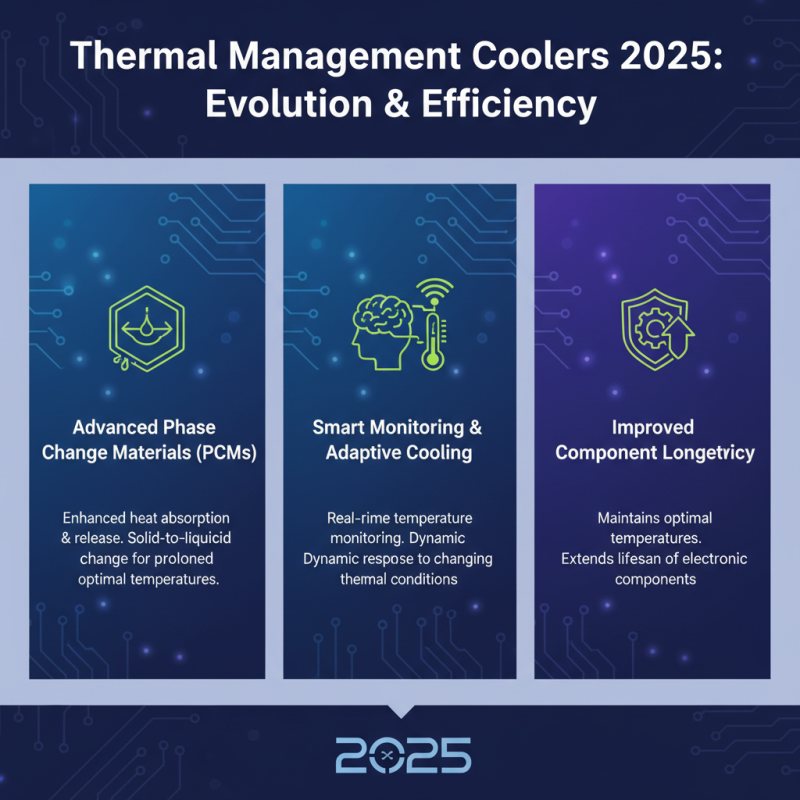

As we approach 2025, the landscape of thermal management coolers is evolving with several key technologies that promise to enhance efficiency and performance. One notable advancement is the incorporation of advanced phase change materials (PCMs) which enable better heat absorption and release mechanisms. These materials change states between solid and liquid, allowing the cooler to maintain optimal temperatures longer, thus improving the longevity of the components they protect. Moreover, the integration of smart technology for real-time temperature monitoring is gaining traction, allowing for adaptive cooling solutions that respond dynamically to changing thermal conditions.

Another significant technology making waves in thermal management is the use of nanofluids. These specially engineered fluids, containing nanoparticles, demonstrate enhanced thermal conductivity compared to conventional coolants. Their application can lead to more effective heat transfer and reduced thermal resistance within cooling systems. Furthermore, innovations in compact design and lightweight materials are driving the development of smaller and more efficient coolers that do not compromise performance, making them ideal for diverse applications from consumer electronics to industrial settings. These advancements highlight the direction of thermal management technologies in 2025, where efficiency, adaptability, and compactness are pivotal.

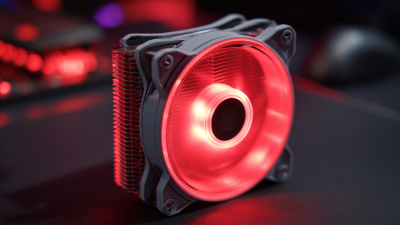

When evaluating cooling efficiency in thermal management solutions, several key metrics and performance indicators come into play. First and foremost, the thermal conductivity of the cooler material is crucial. Higher thermal conductivity allows for more effective heat dissipation, which is essential in maintaining optimal operational temperatures. Additionally, the cooler's surface area should be considered, as larger surface areas facilitate better heat exchange with the environment, enhancing cooling performance.

Another vital performance indicator is the cooling capacity, often measured in watts. This metric indicates how much heat the cooler can absorb and dissipate in a given timeframe, reflecting its suitability for specific applications. Furthermore, the temperature differential, which refers to the difference between the inlet and outlet temperatures, provides insight into the cooler's efficiency.

Evaluating these metrics in the context of your specific thermal management needs is key to selecting the right cooler for effective temperature regulation. Finally, reliability and endurance under varying operational conditions are also important, as they ensure long-term performance without significant degradation, making them essential considerations for informed decision-making in thermal management.

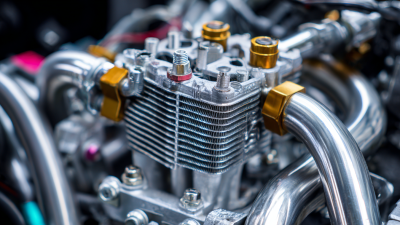

When selecting the best thermal management cooler, material considerations play a crucial role in ensuring optimal performance and durability. Two of the primary factors to evaluate are thermal conductivity and mechanical durability. According to a 2023 report by the Thermal Management Association, materials with high thermal conductivity, such as copper and aluminum, are often preferred for heat dissipation as they efficiently transfer heat away from critical components.

Specifically, copper has a thermal conductivity rating of approximately 400 W/mK, significantly outperforming aluminum, which averages around 205 W/mK. This difference underscores the importance of conducting thorough material research to align performance with application needs.

Durability is equally essential; the materials used in thermal coolers must withstand environmental stresses and thermal cycling. A study from the Institute of Thermal Engineering found that composites and advanced alloys can offer both high heat conduction and resistance to wear and corrosion, thus ensuring longevity in challenging conditions.

For instance, alloys such as aluminum 6061 provide a good balance of strength and scalability, making them advantageous for both lightweight designs and robust applications. Selecting the right material based on these factors not only enhances thermal performance but also contributes to the cooler’s overall lifespan, making it a critical consideration for users in 2025 and beyond.

In 2025, the landscape of thermal management solutions is evolving rapidly, driven by advancements in technology and a growing emphasis on sustainability. One of the most notable market trends is the increased adoption of passive cooling solutions. These systems utilize natural processes, such as convection and radiation, to dissipate heat without the need for high-energy consumption, making them an eco-friendly option ideal for various applications, including consumer electronics and industrial machinery.

Innovation is also at the forefront of thermal management, with new materials playing a crucial role in enhancing performance. The development of phase change materials (PCMs) and advanced composites enables more efficient heat transfer and temperature regulation, which is increasingly important as devices become more compact and energy-dense. Additionally, smart thermal management systems that integrate IoT technology are gaining traction, allowing for real-time monitoring and adjustments to optimize cooling efficiency and prolong the lifespan of components. These innovations reflect the industry's response to the dual demands of improved performance and environmental responsibility, setting the stage for a more efficient thermal management future.