Selecting the appropriate Air Cooled Heat Exchanger (ACHE) is critical for optimizing industrial processes and enhancing energy efficiency. As industries strive for sustainability and cost-effectiveness, the role of ACHEs has gained prominence, particularly in sectors such as oil and gas, power generation, and chemical manufacturing. According to a recent market research report by Fortune Business Insights, the global heat exchanger market is projected to reach USD 18.2 billion by 2028, with air cooled variants gaining traction due to their lower operational costs and reduced water consumption. Furthermore, a study from the International Energy Agency indicates that implementing efficient heat exchangers can lead to energy savings of up to 30% in large-scale operations. Consequently, understanding the key factors in choosing the right Air Cooled Heat Exchanger is essential for industries aiming to improve their environmental footprint while maintaining operational efficiency.

When selecting the right air-cooled heat exchanger for industrial applications, it’s essential to accurately identify your cooling requirements to ensure effective heat exchange. Understanding the specific thermal demands of your operations allows you to choose a heat exchanger that operates efficiently and meets the necessary performance standards. For example, the use of integrated latent heat thermal energy storage systems can significantly enhance cooling efficiency for industrial processes when configured correctly.

**Tips:** Start by assessing your facility's cooling load, taking into account factors like ambient temperature, desired outlet temperature, and the heat load from equipment. Additionally, consider seasonal variations in temperature and humidity which can impact cooling efficiency. In recent studies, it has been found that optimizing the design of cooling systems can lead to substantial energy savings, underscoring the importance of precise requirement identification.

Moreover, newer technologies, such as nanofluids in immersion cooling systems, have shown promise in improving heat transfer efficiency. Incorporating advanced materials and configurations can optimize the overall thermal performance of heat exchangers. Look into innovative solutions, like the application of energy geo-structures which can synergistically work with air-cooled systems to maximize cooling efficiency while minimizing energy consumption.

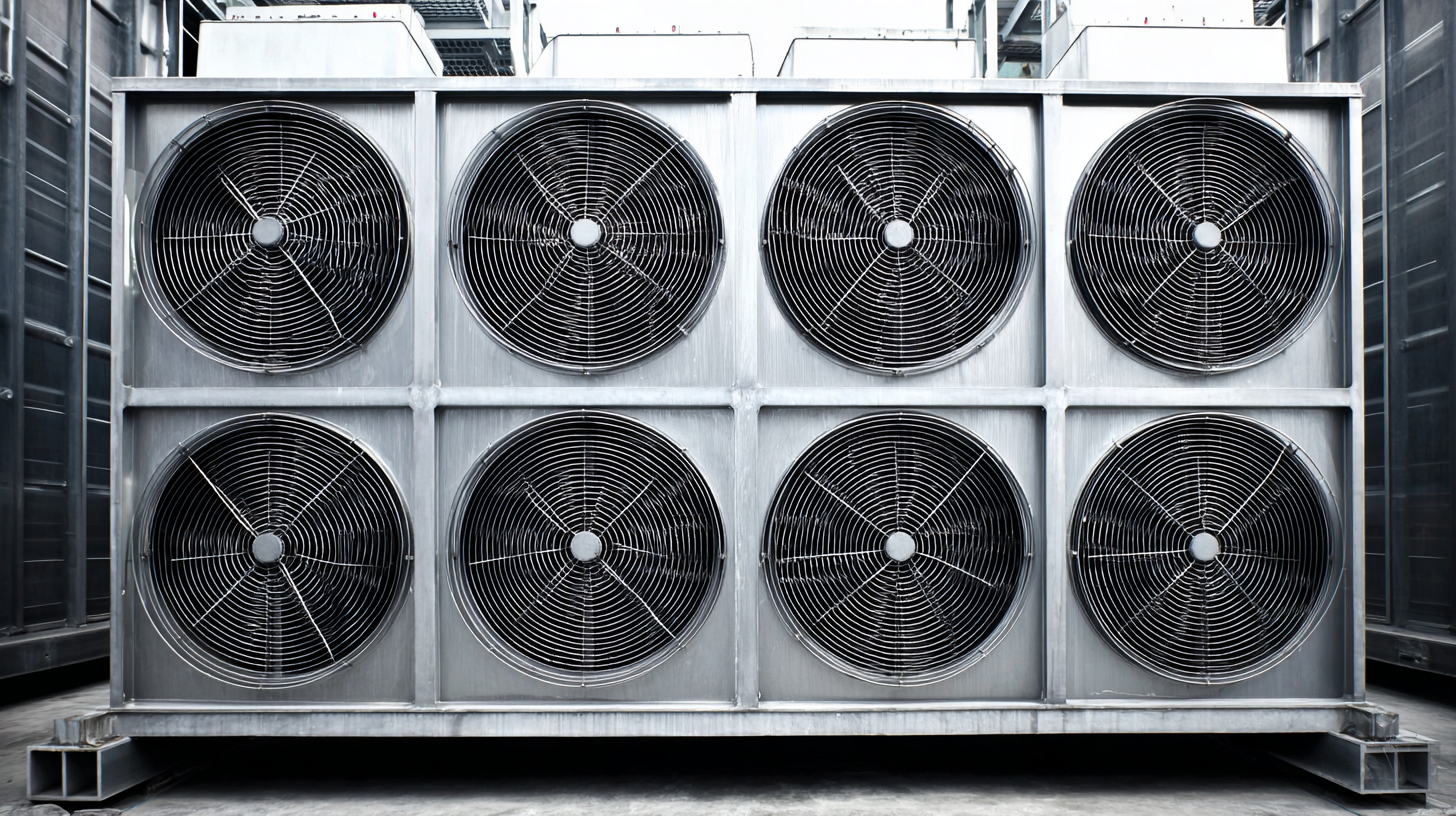

When selecting the appropriate air-cooled heat exchanger for industrial applications, understanding the different types available is crucial.

Air-cooled heat exchangers come in various designs, each suited for specific operational environments.

Recent studies have explored innovations such as perforated dimple and protrusion fins, which significantly enhance heat transfer by optimizing airflow.

These advanced fin designs can lead to improved efficiency, making them ideal for plants aiming to maximize thermal performance.

Moreover, the air-cooled heat exchanger market is expected to grow substantially, projected to reach USD 5.11 billion by 2034.

This growth is driven by the increasing demand for efficient cooling solutions across various industries, including power generation and chemical processing.

As industries continue to focus on sustainability and efficiency, technologies such as encapsulated phase change materials for dry cooling applications are becoming more prominent.

Analyzing these options allows industrial operators to make informed decisions based on their specific cooling needs, taking into account factors like environmental conditions and budget constraints.

When selecting an air cooled heat exchanger, evaluating performance metrics and efficiency standards is crucial. These metrics offer insights into how well the heat exchanger will function under specific industrial conditions. Key performance indicators, such as heat transfer coefficient and pressure drop, determine the effectiveness of the unit in transferring thermal energy while minimizing energy losses. By analyzing these metrics, industries can ensure that the selected heat exchanger aligns with their operational requirements and maximizes performance.

Efficiency standards, such as those set by the American Society of Mechanical Engineers (ASME) and other regulatory bodies, are also essential in this evaluation process. Compliance with these standards guarantees that the heat exchanger not only meets minimum efficiency requirements but is also safe and reliable in operation. Industries should assess the thermal efficiency rating and the sustainability of the materials used in the heat exchanger's construction. By thoroughly evaluating both performance metrics and efficiency standards, businesses can make informed decisions that enhance their thermal management systems and support overall operational efficiency.

When selecting an air-cooled heat exchanger for industrial applications, installation and maintenance considerations are paramount. Proper installation is crucial, as it influences the long-term performance and efficiency of the system. Factors such as the ambient environment and airflow patterns must be assessed to ensure optimal placement. For instance, systems exposed to corrosive elements should incorporate protective measures to mitigate damage, which can significantly extend the lifespan and reduce unexpected downtime.

Maintenance also plays a vital role in the reliability of heat exchangers. Regular inspections and monitoring can prevent issues such as fouling or corrosion, which, if left unaddressed, could lead to major operational disruptions. The advent of artificial intelligence in monitoring technologies offers new avenues for predictive maintenance, allowing operators to optimize their upkeep routines. As industries increasingly prioritize sustainability, integrating these advanced maintenance strategies will be essential to enhance the efficiency of heat exchangers while reducing their environmental impact.

When selecting an air-cooled heat exchanger, budgeting plays a crucial role, particularly in understanding the balance between cost and quality. It's essential to assess not just the initial purchase price, but also the long-term operational efficiency and maintenance expenses. While cheaper options may seem attractive upfront, they can lead to higher energy costs and frequent repairs, which accumulate over time. Investing in a high-quality heat exchanger often results in better performance and reliability, ultimately providing value that outweighs the higher initial expenditure.

Furthermore, understanding the specific requirements of your industrial application can help guide your decision. Engaging with manufacturers to discuss the design, materials, and performance ratings can illuminate potential trade-offs between different models. Quality assurance and certifications can also indicate a product's reliability, justifying a higher price tag. By incorporating a comprehensive analysis of both budget and quality, businesses can make informed choices that enhance their operational efficiency while adhering to financial constraints.

| Model | Heat Transfer Area (m²) | Material | Cost ($) | Efficiency (%) | Warranty (years) |

|---|---|---|---|---|---|

| Model A | 150 | Carbon Steel | 3000 | 85 | 2 |

| Model B | 200 | Stainless Steel | 4500 | 88 | 3 |

| Model C | 175 | Aluminum | 4000 | 90 | 5 |

| Model D | 120 | Copper | 2500 | 82 | 1 |