Selecting the most suitable heat exchanger technology for a specific application is a critical task that can significantly influence the efficiency and effectiveness of thermal processes in various industries. Heat exchangers play a vital role in energy conservation and process optimization, serving as essential components in heating, cooling, and heat recovery systems. As advancements in technology continue to emerge, the variety of heat exchanger designs and materials available has expanded, creating a need for careful evaluation to maximize performance and reduce operational costs.

Understanding the unique requirements of your application is paramount when navigating through the myriad of heat exchanger technologies. Factors such as fluid properties, temperature ranges, pressure conditions, and space constraints must be considered to ensure the chosen solution provides optimal heat transfer efficiency. Additionally, differentiating between types such as shell-and-tube, plate, and finned tube heat exchangers can help in identifying the best fit for your specific requirements. In this guide, we will explore the crucial aspects to look for when choosing the right heat exchanger technology, enabling you to make informed decisions that align with your operational objectives.

Heat exchangers are crucial components in various industries, facilitating the transfer of heat between two or more fluids without mixing them. Understanding the fundamental concepts behind different heat exchanger technologies can significantly impact the efficiency and effectiveness of your application. The two primary types of heat exchangers are shell-and-tube and plate types, each offering distinct advantages depending on the operational requirements. Shell-and-tube heat exchangers are known for their robustness and capability to handle high-temperature and high-pressure scenarios, making them suitable for heavy industrial applications.

On the other hand, plate heat exchangers provide a larger surface area for heat transfer in a more compact design, yielding higher efficiency in space-constrained environments. Their modular nature allows for easy maintenance and adaptability, which is often advantageous in processes with varying flow rates. Other technologies such as air-cooled and double-pipe heat exchangers can also be tailored for specific conditions, emphasizing the importance of understanding the characteristics of each type to select the most appropriate solution. Evaluating factors like fluid properties, temperature ranges, pressure drops, and maintenance needs is essential in making an informed decision about the right heat exchanger technology for your unique application.

| Heat Exchanger Type | Efficiency (%) | Operating Temperature (°C) | Material | Typical Applications |

|---|---|---|---|---|

| Shell and Tube | 80-90 | -200 to 400 | Stainless Steel | Oil Refineries, Power Plants |

| Plate | 85-95 | -120 to 200 | Aluminum, Stainless Steel | Food Processing, HVAC |

| Air Cooled | 70-80 | 0 to 150 | Carbon Steel | Power Generation, Chemical Plants |

| Double Pipe | 70-85 | -100 to 300 | Copper, Aluminum | Cooling Systems, Chemical Processing |

| Spiral | 90-95 | -200 to 250 | Stainless Steel | Waste Heat Recovery, Chemical Industry |

When selecting the best heat exchanger technology for your application, understanding key factors can significantly influence the efficiency and performance of the system. One of the primary considerations is the type of heat transfer required—whether it is for heating, cooling, or recovering waste heat. This decision impacts the design of the heat exchanger, as various technologies, like shell and tube or plate heat exchangers, possess distinct efficiencies and pressures that cater to different operational needs.

Another important aspect is the fluids involved in the heat exchange process. The physical and chemical properties of the fluids—such as their temperatures, pressures, and potential for fouling—will determine the material selection and design configuration of the heat exchanger. Additionally, operating conditions, such as flow rates and thermal load, must be evaluated since they will affect the overall size and layout of the exchanger. Finally, considerations around maintenance and operational costs should guide the selection process to ensure that the chosen technology provides not only optimal performance but also long-term reliability and economic feasibility.

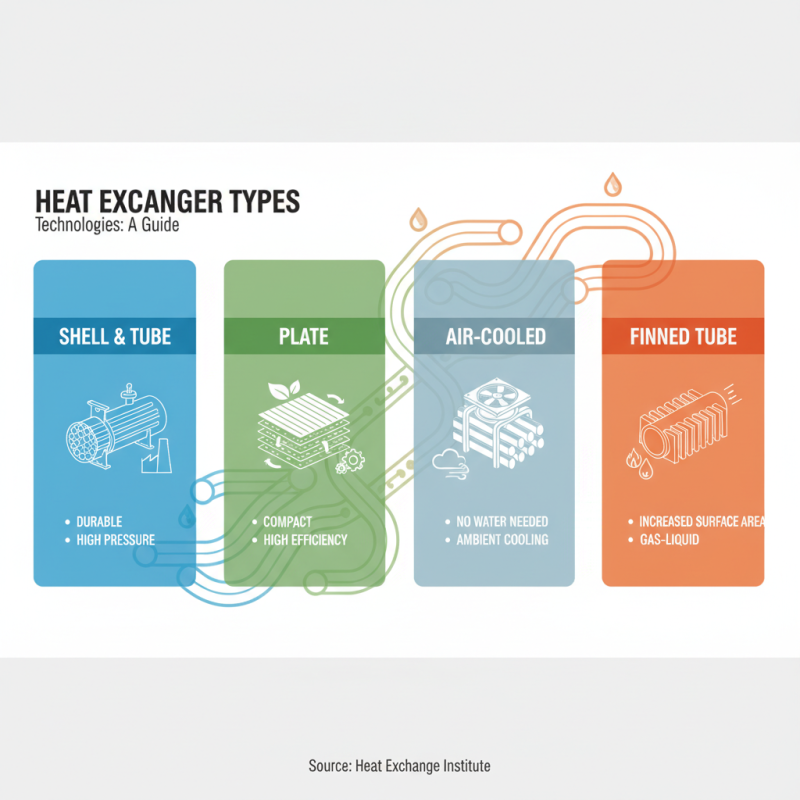

When selecting the best heat exchanger technology for your application, it's crucial to understand the differences between the various types of heat exchangers available. The main categories include shell and tube, plate, air-cooled, and finned tube heat exchangers. Each type boasts unique advantages tailored to specific industrial needs. For instance, according to the Heat Exchange Institute, shell and tube heat exchangers are known for their durability and ability to handle high pressures, making them suitable for applications in chemical processing and power generation.

To guide your selection, consider the operational conditions such as temperature, pressure, and fluid types. Plate heat exchangers, characterized by their compact design and high efficiency, are often preferred for food processing and HVAC applications. A report by Allied Market Research highlights that the market for plate heat exchangers is expected to grow at a CAGR of 6.2% from 2023 to 2030, underscoring their rising prominence in energy recovery and environmental applications.

**Tips:** When evaluating heat exchanger options, ensure you account for maintenance needs. Simpler designs typically allow for easier cleaning and serviceability. Additionally, consider the initial cost against the operational efficiency; investing in a more expensive, high-efficiency unit could lead to significant savings in energy costs over time.

When selecting the best heat exchanger technology for your application, evaluating efficiency and performance metrics is crucial. Efficiency can often be quantified by the overall heat transfer coefficient, which reflects how well the heat exchanger manages to transfer heat under given operational conditions. Factors such as temperature difference, fluid velocities, and the specific heat capacities of the fluids involved play significant roles in defining this metric. Understanding these parameters can aid in identifying which design—be it shell-and-tube, plate, or finned-tube—is most suited to optimize performance in your particular scenario.

Performance metrics extend beyond mere efficiency and include considerations such as pressure drop and maintenance requirements. A heat exchanger that operates with a lower pressure drop can help maintain system energy efficiency, reducing operating costs. Moreover, assessing the ease of cleaning and maintenance is vital, as performance can significantly decline over time due to fouling. In environments where high reliability and longevity are paramount, prioritizing these performance metrics will ensure that the selected heat exchanger not only meets immediate needs but also continues to perform effectively throughout its operational lifespan.

When selecting a heat exchanger, it's essential to consider the specific application requirements that influence performance and efficiency. First, assess the operating conditions, including temperature and pressure ranges, as these factors directly affect the choice of materials and design. For instance, certain applications may demand corrosion-resistant materials or specific designs like shell-and-tube or plate heat exchangers to manage high heat transfer rates efficiently. Understanding the thermal and physical properties of the fluids involved, such as viscosity and phase (gas or liquid), is also crucial, as these will dictate how heat transfer occurs and the overall size and complexity of the unit.

Another important consideration is the maintenance and cleaning needs of the heat exchanger. In applications where fouling is likely, selecting a design that allows easy access for cleaning will minimize downtime and maintenance costs. Additionally, consider how the heat exchanger will interact with other system components; for example, flow rates and pressure drops can significantly impact overall system performance. By thoroughly analyzing these application-specific factors, it becomes easier to choose the most suitable heat exchanger technology that not only meets operational demands but also enhances overall system efficiency.