As we approach 2026, the need for an effective Thermal Management Cooler becomes increasingly vital. Rapid advancements in technology have led to devices generating more heat than ever before. Whether it's for gaming, data centers, or home appliances, efficient cooling solutions are essential.

Choosing the best Thermal Management Cooler can be challenging. Many products claim to excel, yet very few deliver on promises. It's crucial to assess performance, durability, and design. Some coolers fail under high loads, while others work optimally but decrease efficiency over time.

In this evolving landscape, users must remain vigilant. What works today might not suffice tomorrow. Therefore, understanding various cooling technologies is important. Selecting the right Thermal Management Cooler is a nuanced task that requires careful consideration and reflection on personal needs.

Thermal management is crucial in various sectors today. In 2026, this importance only grows. With increasing demands for efficiency, the need for effective cooling solutions becomes more pressing. Industries rely heavily on thermal management to ensure optimal performance of equipment. Without it, productivity declines.

Understanding heat transfer methods can improve system designs. Many rely on passive cooling systems, yet they often fall short under heavy loads. Active cooling solutions can provide better results but may increase energy consumption. This requires a careful balance between efficiency and sustainability.

It's essential to analyze the specific needs of each application. A one-size-fits-all approach rarely works well. Challenges exist in selecting the right materials and technologies. Each decision impacts long-term performance and reliability. Finding optimal solutions is an ongoing journey, not a destination.

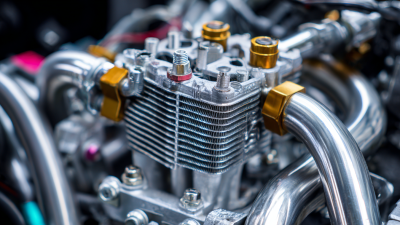

As we look toward 2026, thermal management solutions will evolve significantly. Efficient heat dissipation is crucial in various industries, including electronics and automotive sectors. Advanced materials like graphene and carbon nanotubes are becoming essential for improving the performance of coolers.

Innovative cooling technologies will also gain traction. Liquid cooling systems are gaining attention for their ability to transfer heat efficiently. Phase-change materials could offer new avenues for effective heat management. These solutions promise better thermal regulation at reduced sizes. However, challenges remain in scaling these technologies for mass production. Integration into existing systems may also present hurdles that need addressing.

Sustainability will play a pivotal role in thermal management strategies. Recycling materials and reducing waste will be more crucial than ever. There's a need for efficient designs that minimize environmental impacts. As the demand increases, balancing performance and eco-friendliness becomes essential. Companies must navigate these complexities while embracing new technologies for effective solutions.

As technology evolves, choosing the right thermal management cooler becomes critical. In 2026, several coolers stand out for their features and performance metrics. Effective thermal management coolers must efficiently dissipate heat while maintaining optimal operating conditions. Some models offer enhanced airflow. This improves cooling efficiency significantly.

Many new models feature advanced materials for durability. Lightweight aluminum or copper alloys are common, yet some setups seem bulky and challenging to install. User-friendly designs should be a priority. A well-designed cooler can make maintenance much easier. However, not all manufacturers focus on making their products user-centric. Ease of installation is sometimes overlooked.

Performance metrics are a vital aspect of selecting the right cooler. A lower thermal resistance rating is generally desirable. Additionally, coolers with adjustable fan speeds allow for better control over performance. Unfortunately, some models may not provide adequate noise levels. Balancing performance and noise is tricky. Users often find themselves compromising on one aspect for the other.

The thermal management cooler market is evolving. Innovations in materials and designs are crucial. Lightweight yet efficient coolers are gaining attention. New trends highlight the use of eco-friendly materials. Sustainable options appeal to both consumers and manufacturers. However, not all products meet expectations.

Performance remains a key factor. Some coolers struggle under heavy loads. Testing shows that efficiency can vary significantly. Many users desire compact designs without sacrificing cooling power. The push for quieter operation is prevalent. Noise reduction technology is becoming standard. Yet, some solutions still fall short in real-world scenarios.

The forecast indicates steady growth. More industries are recognizing the importance of thermal management. This growth can lead to a crowded marketplace. Consumers may face confusion due to overwhelming choices. Understanding specific needs is vital for making informed decisions. Future projections hint at further advancements, but challenges lie ahead. As technology progresses, ongoing assessments will be necessary.

This bar chart displays the projected market share of various thermal management coolers for the year 2026. As seen, active coolers are expected to dominate the market, followed by passive and liquid coolers, indicating trends towards more efficient cooling solutions in various industries.

When evaluating thermal management coolers, efficiency is crucial. Thermal conductivity determines how well a cooler can transfer heat. Materials like copper and aluminum are common. However, not all coolers use these effectively. Some designs may emphasize aesthetics over performance, leading to higher temperatures.

Heat dissipation rates vary widely. A cooler might absorb heat well but fail to release it quickly. The airflow around it plays a significant role. Even with the best materials, poor airflow can hinder performance. Testing different setups can reveal surprising results. It’s important to monitor the temperatures during operation to ensure optimal performance.

Tips: Always consider airflow design. A good cooler with poor airflow won't perform well. Experiment with different placements. Sometimes, a slight adjustment can improve cooling efficiency dramatically. Don't overlook the basics. Regular cleaning of dust can also enhance performance.

| Cooler Type | Thermal Conductivity (W/m·K) | Heat Dissipation Rate (W) | Efficiency Rating (%) |

|---|---|---|---|

| Air Cooler | 200 | 150 | 85 |

| Liquid Cooler | 400 | 250 | 90 |

| Peltier Cooler | 150 | 120 | 80 |

| Phase Change Cooler | 250 | 200 | 92 |

| Heat Pipe Cooler | 300 | 180 | 87 |