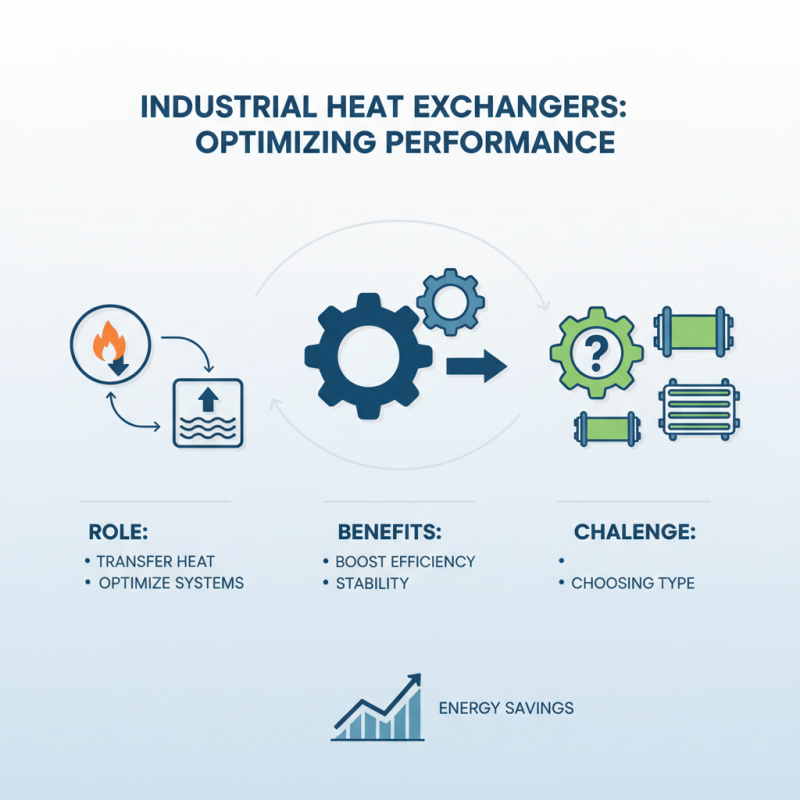

In today's manufacturing landscape, the efficiency of processes is crucial. An Industrial Heat Exchanger plays a vital role in improving energy use and reducing waste. These systems transfer heat between two or more fluids, enhancing overall productivity.

Choosing the right Industrial Heat Exchanger can be challenging. Various types exist, each designed for specific applications. Some industries may overlook the significance of selecting the appropriate model. This oversight can lead to inefficiencies in operations. Additionally, factors like maintenance and installation costs are often underestimated.

Understanding the details is essential. The heat transfer efficiency of these exchangers dictates operational performance. Investing time and resources in the right heat exchanger can yield significant returns. Therefore, exploring the best options available is critical for manufacturers seeking maximum efficiency.

In the field of industrial applications, heat exchangers play a vital role. They help transfer heat from one medium to another, optimizing performance across various systems. Effective heat exchangers boost energy efficiency and maintain operational stability. Choosing the right type can be challenging, though.

When evaluating heat exchangers, consider factors like material, design, and maintenance ease. Shell and tube designs offer durability but may require more space. Plate heat exchangers save space and provide effective heat transfer. Some options can present cleaning difficulties, affecting long-term efficiency. Enhancing system performance often means balancing constraints like cost and space.

Not every heat exchanger performs perfectly. Some may struggle under extreme conditions, leading to failure. Regular monitoring is essential to prevent inefficiencies. Identifying the right heat exchanger is an intricate process that requires careful planning. Explore various options, and always consider your specific operational needs for optimal results.

Efficiency in industrial heat exchangers depends on various critical factors. One major element is the design type. Each exchanger type, such as shell-and-tube or plate heat exchangers, offers unique operational benefits. According to a report by the American Society of Mechanical Engineers, choosing the wrong design can reduce efficiency by as much as 20%. Fluid dynamics also play a significant role. The flow rate affects heat transfer; too high can lead to turbulence, causing inefficiencies.

Another key factor is the materials used. Corrosion-resistant materials may increase initial costs, but they improve longevity and overall efficiency in the long run. Research indicates that materials with higher thermal conductivity can boost heat transfer rates. However, the trade-off often lies in their maintenance requirements. Additionally, fouling can significantly decrease performance. Regular cleaning protocols are essential yet often overlooked. Ignoring fouling can drop heat exchanger efficiency by up to 50%. Regular maintenance is a necessary investment in maximizing operational efficiency.

This chart illustrates the efficiency percentages of various types of industrial heat exchangers, highlighting their performance characteristics. Proper understanding of these efficiencies is crucial for selecting the right heat exchanger for maximum operational effectiveness.

When selecting an industrial heat exchanger, understanding the various types is crucial. Shell and tube heat exchangers are commonly used in large-scale applications. They have a high heat transfer efficiency but can require significant maintenance. In contrast, plate heat exchangers are smaller and easier to clean. Their compact design allows for efficient heat transfer but may not withstand high pressures.

Another type is air-cooled heat exchangers. They use air to remove heat, making them energy-efficient. A report from the U.S. Department of Energy suggests they can reduce energy consumption by up to 30%. However, they can be less effective in humid environments, which raises questions about sustainability in various climates.

Each type comes with trade-offs. For instance, while finned tube heat exchangers enhance heat transfer, they can also be prone to fouling, leading to higher operational costs. It's essential to weigh the pros and cons based on specific industrial needs. Every choice impacts efficiency and productivity, prompting reflection on long-term operational strategies.

| Type | Pros | Cons | Typical Applications | Efficiency Rating |

|---|---|---|---|---|

| Shell and Tube | High heat transfer efficiency | Space-consuming | Oil refineries, chemical processing | 85% |

| Plate | Compact size | Limited pressure capabilities | HVAC, food processing | 90% |

| Air Cooled | No water usage | Less effective in high heat scenarios | Power plants, petrochemical | 80% |

| Double Pipe | Simple design | Low efficiency | Heating applications | 75% |

| Spiral | High thermal efficiency | More expensive | Waste heat recovery | 88% |

| Finned Tube | Enhanced surface area | Difficult maintenance | Cooling systems | 82% |

| Microchannel | Small footprint | Fragile construction | Automotive applications | 92% |

| Heat Recovery | Increases system efficiency | High initial cost | Industrial exhaust systems | 95% |

| Electric | No moving parts | Higher energy costs | Plastic manufacturing | 85% |

| Condenser | Effective for phase change | Requires cooling medium | Power generation | 90% |

Proper maintenance is crucial for extending the life of heat exchangers. Regular inspections help identify wear and tear early. Cleaning the surfaces improves thermal efficiency. Residue buildup can lead to poor performance. Scheduling routine maintenance checks is a smart move. It may seem tedious, but the benefits are significant.

Monitoring operating conditions is also essential. Collect data on temperatures and pressures. An unusual spike might indicate a problem. Ensure that all fittings and seals are tight. Leaks can cause serious issues. A small leak can lead to major downtime, affecting productivity and costs.

Training staff on basic maintenance can be overlooked. Employees should know how to clean and inspect units. Foster a culture of proactive care. Document all maintenance activities; this helps track the history and condition of the heat exchangers. Without records, it’s challenging to know when to act. Use this information to improve processes. Frequent review of operational data ensures long-term efficiency.

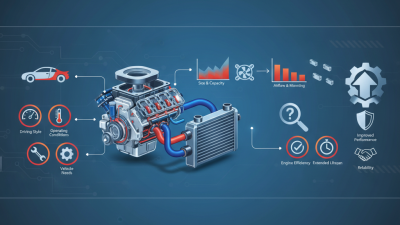

Innovative technologies in heat exchanger design have transformed energy efficiency across various industries. Recent studies indicate that advanced designs can improve efficiency by up to 30%. Enhanced heat transfer surfaces and new materials play crucial roles in this improvement. For instance, using microchannel designs can drastically reduce energy consumption. These channels facilitate better heat transfer, allowing for smaller and lighter exchangers.

Another critical area is the incorporation of smart technology. Sensors and IoT integration offer real-time monitoring. This data helps in optimizing performance and identifying inefficiencies quickly. Research suggests that predictive maintenance can reduce downtime by nearly 25%. However, not all facilities are adopting these technologies. Some industries remain hesitant, citing high initial costs.

Moreover, advancements in computational fluid dynamics (CFD) have refined heat exchanger simulations. This technology allows for precise modeling of heat and fluid flow. Yet, many engineers still rely on outdated methods. It’s a stark reminder that progress is uneven across sectors. While some lead the way, others lag behind. This gap in adoption highlights a need for continuous education and innovation in the field.