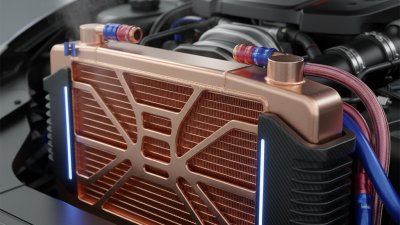

In many industrial applications, a Hydraulic Oil Cooling System is vital for machine performance. These systems help maintain optimal oil temperatures, enhancing efficiency. Properly cooled hydraulic oil can significantly boost the lifespan of machinery and reduce downtime.

Many factors influence the effectiveness of a Hydraulic Oil Cooling System. Choosing the right cooling method can be perplexing. Air-cooled or water-cooled systems each have unique advantages and potential drawbacks. For instance, air-cooled systems may have limited cooling capacity in high-temperature environments.

It is essential to examine the specific needs of your equipment. The choice of a Hydraulic Oil Cooling System should be tailored to the challenges faced. Reflecting on past experiences can uncover areas for improvement. A well-designed cooling system not only supports performance but also saves costs in the long run. Investing in the right technology is crucial for any operational setting.

A hydraulic oil cooling system plays a vital role in maintaining efficient operation. Excessive heat can degrade hydraulic fluid, leading to reduced performance and shorter equipment lifespan. Research indicates that high temperatures can reduce oil viscosity by 10% for every 10°C increase. Monitoring and managing oil temperature is crucial to prevent these issues.

Maintaining optimal temperatures prevents damage and maintains system efficiency. For instance, operating above 80°C can lead to increased wear and tear on components. During heavy operations, the cooling system's capacity can be tested. Regular maintenance checks are essential to ensure radiators and cooling units function properly.

Tip: Schedule routine inspections for your hydraulic cooling system. A small leak can lead to significant heat fluctuations. Be proactive in replacing worn components to avoid system failures. Remember, consistent cooling ensures longer life for hydraulic systems and better overall performance.

Hydraulic oil cooling systems play a crucial role in maintaining equipment efficiency. Various types exist to cater to different needs. One common option is air-cooled systems, which use fans to dissipate heat. These systems are often simple and cost-effective. However, they may struggle in environments with high ambient temperatures. The cooling capacity can be limited as well, leading to potential overheating.

Another popular choice is water-cooled systems, which utilize water to remove heat from the oil. These systems are generally more efficient, especially in high-demand applications. They require a constant water supply, which can pose challenges. Maintenance can also be more demanding than air-cooled options. Some users may overlook the importance of regular checks and cleaning.

There are also heat exchanger systems that provide advanced cooling solutions. They can efficiently manage heat transfer, ensuring optimal performance. However, these setups may require more space and initial investment. Users must weigh the trade-offs between efficiency, cost, and available space. Identifying the most suitable system requires careful reflection on specific operational needs. The choice should align with long-term performance goals.

| Cooling System Type | Description | Efficiency Rating | Cost Estimate ($) | Maintenance Needs |

|---|---|---|---|---|

| Air-Cooled System | Uses air to dissipate heat from hydraulic oil. | 80% | 250 - 400 | Low |

| Water-Cooled System | Utilizes water for heat exchange. | 90% | 500 - 800 | Medium |

| Oil-to-Oil Heat Exchanger | Uses hydraulic oil to cool the hot oil via heat exchange. | 85% | 600 - 900 | High |

| Electronic Cooling System | Incorporates electronic components to manage cooling. | 95% | 800 - 1200 | Very High |

When considering a hydraulic oil cooling system, various factors play a significant role. The size of the system should match your machinery's requirements. A too-small unit may not cool effectively, while an oversized system can lead to unnecessary energy costs. Proper sizing is crucial for performance.

Flow rate is another important factor. Understanding the specific flow rate needed for your hydraulic system ensures optimal cooling. It’s wise to factor in the viscosity of the hydraulic fluid as well. Thicker oils require more energy to pump, impacting your overall efficiency.

Tips: Always assess your working environment. High ambient temperatures can make cooling more challenging. Consider the layout of your facility, as it can affect airflow. Regular maintenance is also essential. A neglected cooling system may lead to overheating and equipment failure. Don't overlook these details.

Efficient hydraulic oil cooling plays a crucial role in equipment performance. It prevents overheating, which can lead to mechanical failures. Studies show that maintaining optimal oil temperatures can increase hydraulic system efficiency by 15% to 30%. This efficiency boost translates into reduced energy consumption and lower operational costs.

When hydraulic systems overheat, oil viscosity can change. This change impacts lubrication and flow rates, leading to premature wear. Reports reveal that nearly 40% of hydraulic system failures are linked to oil overheating. Using an effective cooling system can minimize these risks. For instance, a well-designed cooler can significantly enhance oil cooling by up to 50% in some cases, improving overall equipment lifespan.

Despite the clear benefits, many operators overlook the importance of regular maintenance. Inefficient cooling systems often result in costly downtime. Additionally, some operators may hesitate to invest in advanced cooling technology, fearing upfront costs. However, the long-term savings through improved equipment performance might offset these initial expenses. It is critical to evaluate cooling solutions regularly and reflect on system performance for better outcomes.

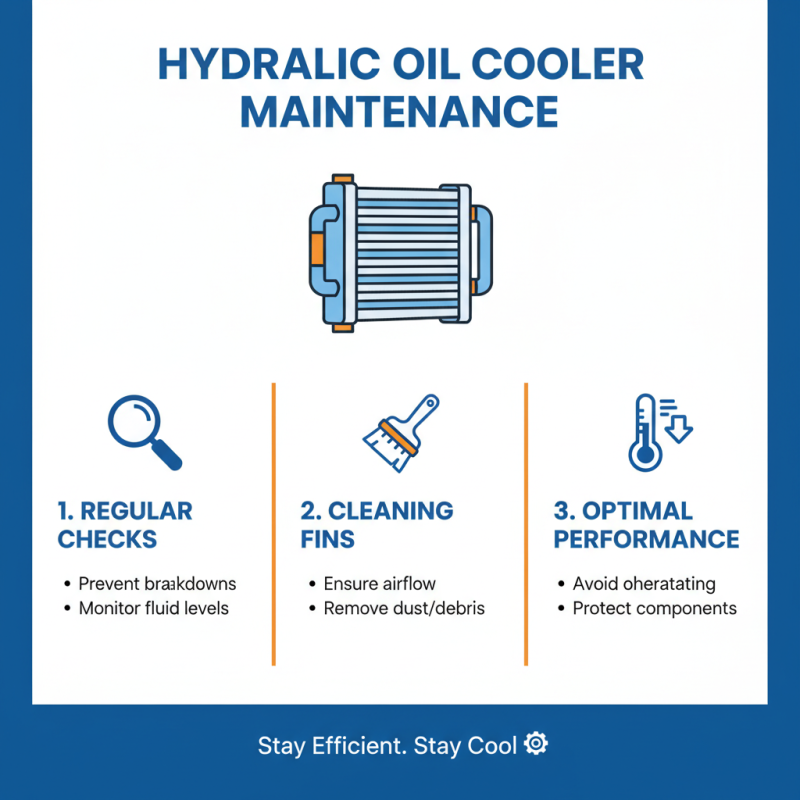

Maintaining the hydraulic oil cooler is crucial for efficient performance. Regular checks can prevent major breakdowns. Clean the cooling fins routinely to ensure optimal airflow. Dust and debris can block airflow, leading to overheating. Keep an eye on fluid levels, too. Low levels can affect cooling efficiency and damage components.

Use the right type of hydraulic oil. Different systems have specific requirements. Mixing oils can lead to chemical reactions that harm the cooler. A periodic oil change is essential, as old oil can lose its effectiveness over time. Check for leaks often. Even a small leak can cause significant issues if ignored.

Also, monitor operating temperatures. If the system runs warmer than usual, there might be a problem. Inspect hoses and connections for wear and tear. Replacing damaged parts early can save time and money. Hydraulic oil coolers are vital to system longevity. Neglecting their maintenance can lead to costly repairs down the line.