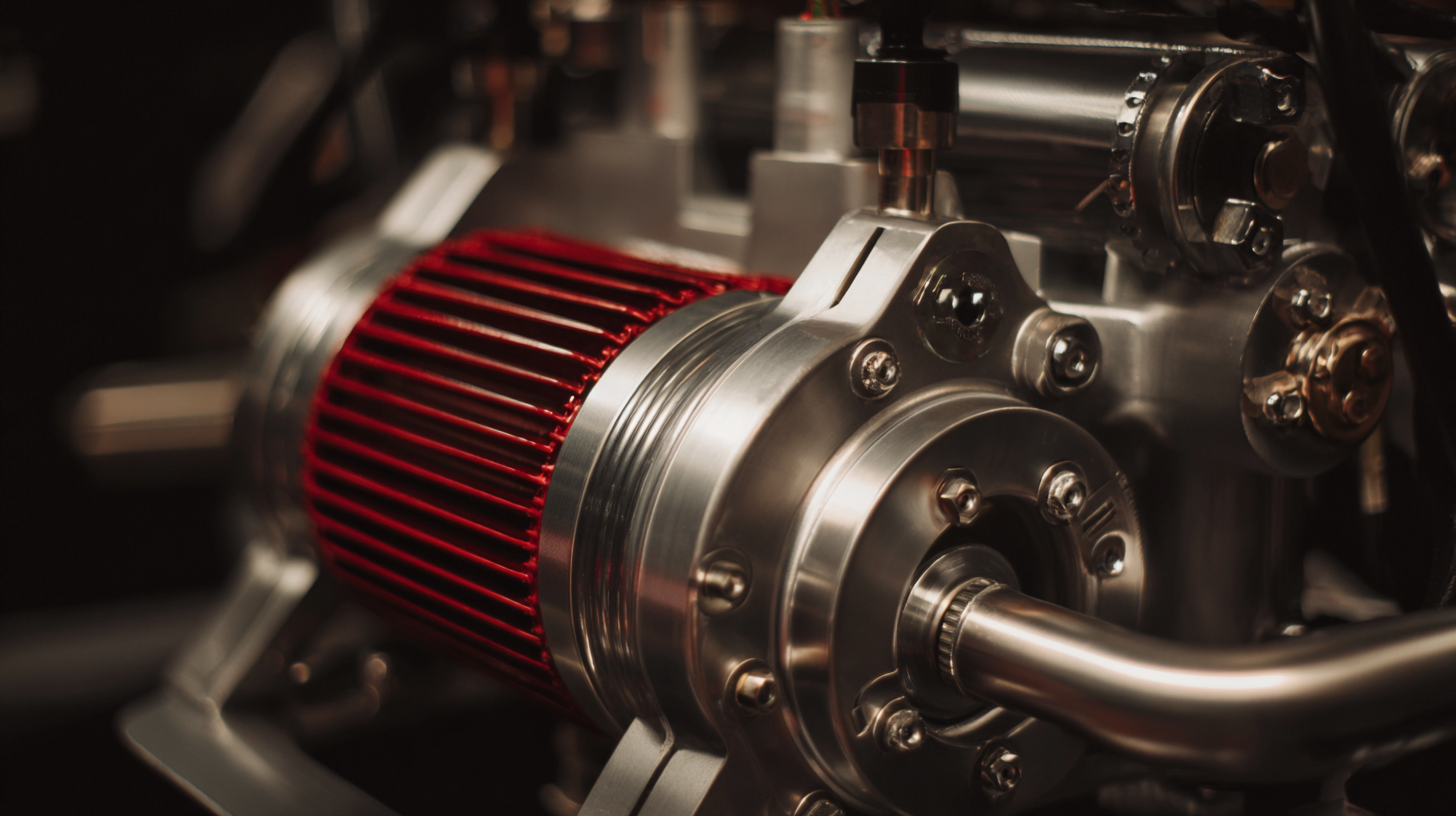

As the automotive industry continues to evolve, the quest for enhanced engine performance and efficiency has led to innovative solutions such as the Air Cooled Oil Cooler. According to a recent report by the Society of Automotive Engineers (SAE), vehicles equipped with air-cooled oil coolers exhibit an impressive increase in thermal management capabilities, which can boost engine performance by up to 20%. This vital component plays a crucial role in maintaining optimal operating temperatures, thus ensuring engine longevity and reliability.

Renowned industry expert Dr. Emily Tran, a leading researcher in engine thermal dynamics, emphasizes the significance of these systems, stating, "The implementation of an Air Cooled Oil Cooler not only safeguards the engine from overheating but also enhances overall efficiency, enabling better fuel economy and lower emissions." As we delve deeper into the workings of air-cooled oil coolers, it becomes evident that their benefits extend beyond mere temperature control to include substantial improvements in engine responsiveness and power output.

In this guide, we will explore the various aspects of Air Cooled Oil Coolers, examining their design, function, and the specific advantages they offer for both standard and high-performance engines. As advancements in technology continue to shape the automotive landscape, understanding the role of air-cooled oil coolers will be essential for anyone looking to unlock the full potential of their engine.

Air cooled oil coolers play a crucial role in enhancing engine performance by significantly reducing operating temperatures. By utilizing ambient air to dissipate heat from the engine oil, these coolers can lower oil temperatures by up to 30%. This reduction is vital as excessive heat can lead to increased viscosity, accelerated oxidation, and potentially detrimental wear on engine components. By maintaining optimal oil temperatures, the engine can operate more efficiently, allowing for better performance and longevity.

Moreover, a cooler engine oil contributes to improved lubrication properties, ensuring that critical engine parts remain protected under high stress. This is especially beneficial in high-performance and heavy-duty applications, where temperature spikes are more common. With enhanced thermal management provided by air cooled oil coolers, drivers can experience not only improved engine efficiency but also a reduction in fuel consumption and emissions. Such benefits make air cooled oil coolers a smart investment for anyone looking to maximize their engine's capabilities.

Air cooled oil coolers play a crucial role in maintaining optimal engine performance by enhancing both oil longevity and efficiency. By effectively dissipating heat from the oil, these coolers prevent overheating, which can lead to unwanted wear and tear on engine components. As the oil temperature remains within an ideal range, its viscosity is preserved, ensuring better lubrication and minimizing friction. This results in a smoother operation of the engine, enhanced power output, and a reduction in the likelihood of mechanical failures.

Moreover, air cooled oil coolers contribute to the overall longevity of the oil itself. Elevated temperatures can accelerate oil degradation, leading to the formation of harmful sludge and deposits. With a well-functioning air cooler, the oil maintains its integrity over extended periods, maximizing its performance and reducing the need for frequent changes. This not only decreases operational costs but also promotes a more environmentally friendly approach by reducing waste. Thus, incorporating air cooled oil coolers is essential for any engine aiming to achieve superior performance and prolonged oil life.

This chart illustrates the impact of air-cooled oil coolers on engine performance and oil longevity across various temperature ranges.

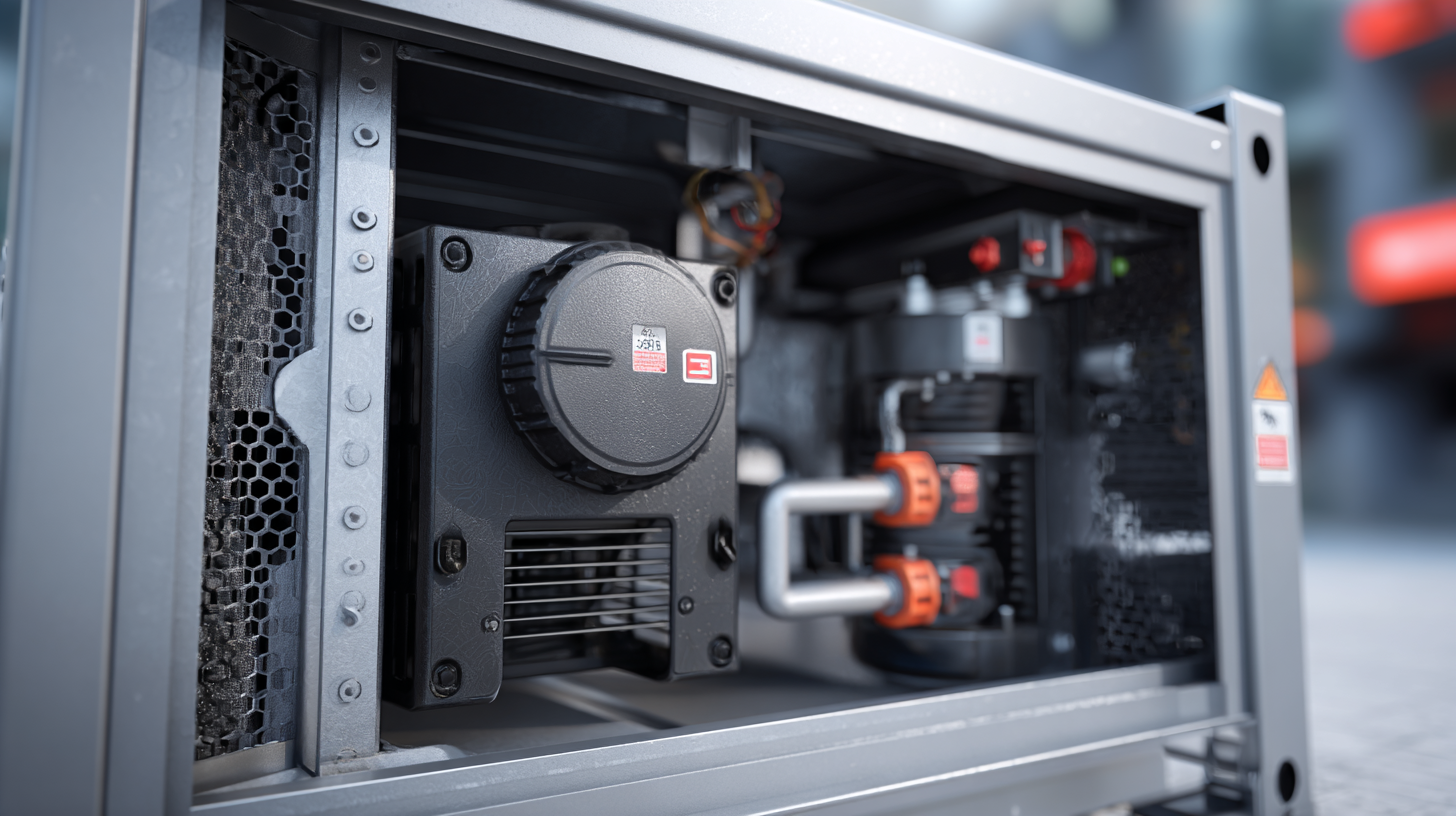

When considering oil cooling systems, the choice between air-cooled and liquid-cooled oil coolers can significantly impact engine performance.

Air-cooled oil coolers, known for their simplicity and lower maintenance needs, offer a more economical solution for many applications. A comparative analysis reveals that while liquid-cooled systems provide superior heat exchange efficiency, air-cooled systems excel in environments where water availability is a concern, making them ideal for remote locations or during off-road operations.

Air-cooled oil coolers, known for their simplicity and lower maintenance needs, offer a more economical solution for many applications. A comparative analysis reveals that while liquid-cooled systems provide superior heat exchange efficiency, air-cooled systems excel in environments where water availability is a concern, making them ideal for remote locations or during off-road operations.

According to recent industry reports, the global market for data center immersion cooling fluids is expected to reach USD 0.84 billion by 2032, highlighting a growing trend towards efficient thermal management solutions. This trend underscores the importance of effective cooling methods in various sectors, including oil and gas, where the performance of air-to-ground heat exchanger systems is critically evaluated. A detailed investigation into finned versus un-finned tube designs for oil pipeline cooling indicates that finned systems can enhance heat dissipation, optimizing the overall cooling efficiency.

Tips: Ensure regular maintenance of your air-cooled oil cooler to prevent debris accumulation which can hinder performance. Additionally, consider using high-quality cooling fluids that are compatible with your system to maximize efficiency and lifespan. Exploring advanced materials in cooler design may also lead to improved heat transfer rates, reinforcing the benefits of an optimized cooling system.

Air-cooled oil coolers are becoming increasingly vital in enhancing engine performance, impacting fuel efficiency significantly. As the automotive engine cooling system market is projected to surpass USD 50.51 billion by 2032, the importance of effective cooling solutions, such as air-cooled oil coolers, cannot be overstated. These systems not only help maintain optimal engine temperatures but also improve fuel efficiency, which is crucial in an industry facing rising costs and environmental regulations.

Tips for maximizing the benefits of air-cooled oil coolers include ensuring proper installation and regular maintenance checks. A well-maintained cooling system can lead to a smoother engine operation and a reduction in fuel consumption. Additionally, with the automotive temperature sensor market expected to grow from $2.20 billion in 2025 to $3.22 billion by 2032, integrating advanced sensors to monitor oil temperatures can provide real-time data to optimize performance further.

Moreover, as consumer demand for fuel-efficient vehicles rises, industries must adapt to embrace innovative solutions. The automotive cooler market's growth underscores this trend, highlighting the potential of technologies like air-cooled oil coolers to enhance vehicle performance while adhering to stricter fuel economy standards. Investing in these systems could be a game changer for manufacturers aiming for sustainability and higher profitability.

The evolution of air cooled oil coolers plays a significant role in optimizing modern engine performance. Recent design innovations have focused on improving thermal efficiency and reducing the overall weight of these systems. Advanced materials, such as aluminum and high-conductivity alloys, have been integrated to enhance heat transfer capabilities while maintaining structural integrity under extreme conditions. Furthermore, innovative fin designs increase surface area exposure to airflow, thereby improving cooling performance without the need for bulky components.

Additionally, advancements in airflow management techniques have led to more effective cooling solutions. Engineers are now implementing computational fluid dynamics (CFD) simulations to analyze and refine the oil cooler configurations, ensuring optimal airflow and minimal drag. These innovations allow for better integration within compact engine layouts, making air cooled oil coolers a viable option for a wide range of modern vehicles. The shift towards smaller and more efficient engines, coupled with these groundbreaking designs, ultimately contributes to better overall vehicle performance and reliability.

| Feature | Description | Impact on Engine Performance |

|---|---|---|

| Thermal Efficiency | Utilizes ambient air to dissipate heat from engine oil | Improves overall thermal management, preventing overheating |

| Compact Design | Smaller size allows for easier integration into modern engine bays | Maximizes space efficiency and enhances engine layout |

| Reduced Weight | Lightweight materials decrease overall vehicle weight | Enhances fuel efficiency and vehicle dynamics |

| Increased Oil Flow | Optimized flow paths facilitate better lubrication | Reduces wear and tear on engine components |

| Enhanced Durability | Robust construction materials resist corrosion | Longevity of components leads to reduced maintenance costs |