In the automotive industry, "Radiator Corrosion Resistance" is a crucial topic for vehicle longevity. Experts like Dr. Samuel Collins emphasize its importance, stating, "Preventing corrosion can significantly extend a vehicle's life." Corrosion in radiators can lead to costly repairs and unsafe driving conditions. It's essential to address this issue effectively.

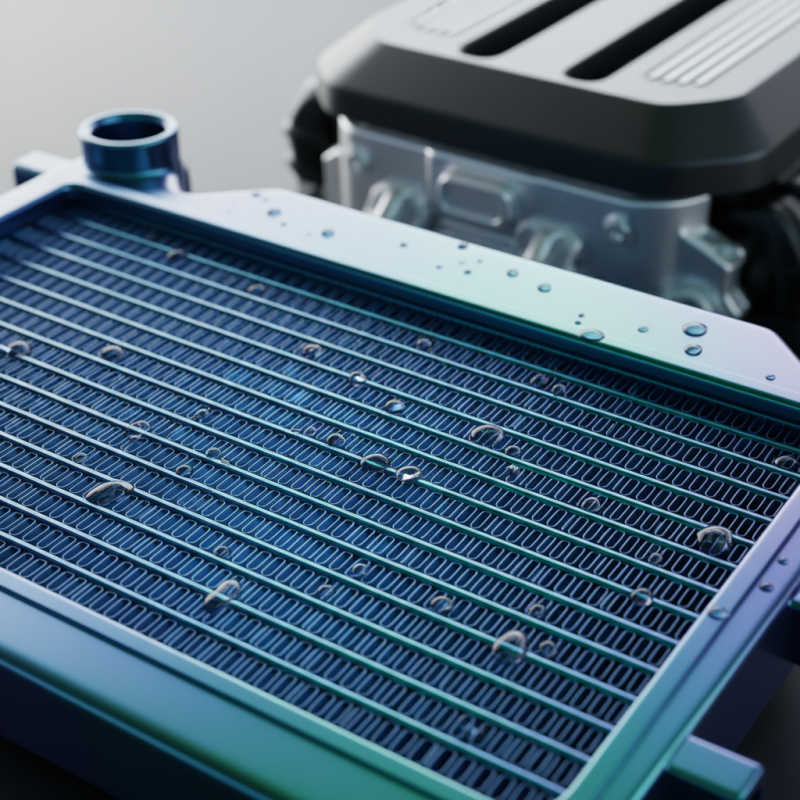

Radiators bear the brunt of harsh environments, including exposure to heat, moisture, and chemicals. Over time, these factors contribute to corrosion, risking engine overheating and inefficiency. Many drivers overlook regular maintenance, which can lead to serious problems. Simple preventive measures could make a significant difference.

Industries are developing new materials and coatings to enhance radiator longevity. Innovations in corrosion resistance are vital for the future of automotive design. As we explore the best solutions for 2026, a focus on "Radiator Corrosion Resistance" will be more important than ever. The quest for durable components challenges us to rethink traditional approaches.

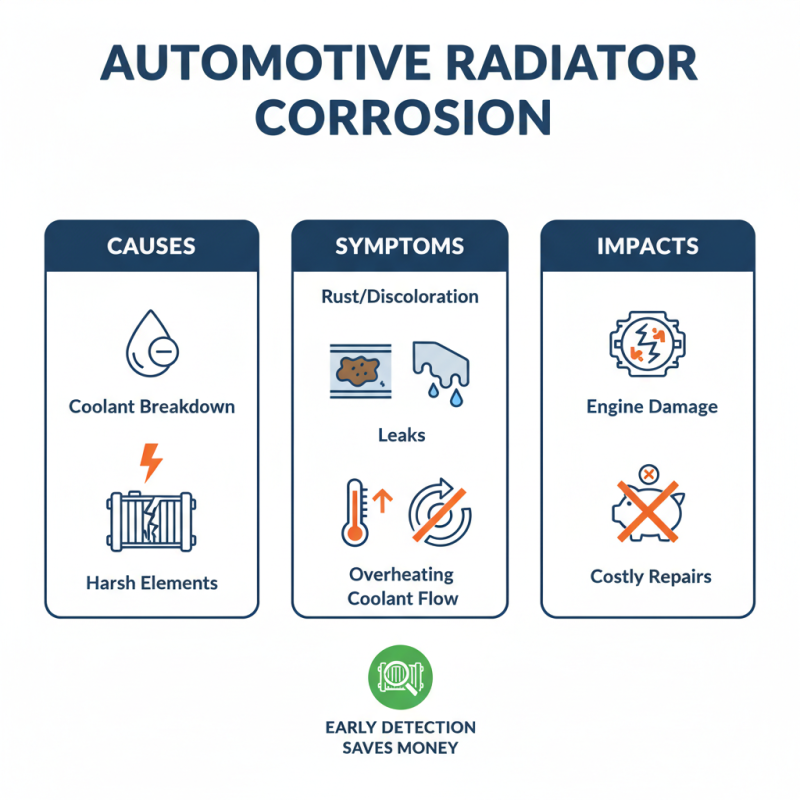

Radiator corrosion is a common issue in vehicles, impacting their overall lifespan. This problem arises from exposure to harsh elements, coolant breakdown, and electrolysis. When the radiator corrodes, it can lead to leaks, overheating, and engine damage. Corrosion symptoms include rust, poor coolant flow, and frequent overheating incidents. Early detection can save money on repairs.

To combat corrosion, regular maintenance is essential. Flushing the coolant system helps remove contaminants and prevent buildup. Additionally, using high-quality coolant can mitigate the risk of corrosion. Maintaining proper coolant levels is equally important. Low coolant can cause overheating, leading to further damage.

It’s easy to overlook these details. Many car owners wait for signs of trouble before acting. However, proactive measures can extend vehicle life significantly. Install magnesium or aluminum anodes to fight corrosion effectively. Periodic inspections can catch corrosion early, but many neglect them. Regular checks are not just an expense; they are an investment in longevity.

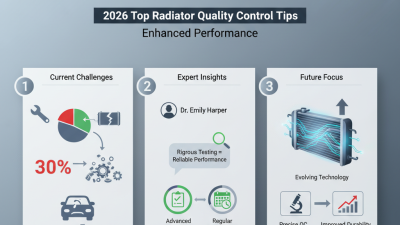

Radiator corrosion is a significant issue facing automotive systems today. A study by the The Society of Automotive Engineers found that corrosion can lead to over 50% of radiator failures. Common causes include electrolysis, poor cooling system maintenance, and the use of improper coolant. These factors can create an environment where corrosion thrives.

Electrolysis occurs when stray electrical currents react with metal. This can lead to pitting and ultimately a leak. Another significant factor is coolant degradation. Most coolants are designed to last only a few years. After this period, protective additives may diminish, leaving the metal vulnerable to rust. Inadequate maintenance can exacerbate these issues, with many drivers overlooking routine inspections.

Indeed, many vehicle owners underestimate the importance of routine checks. A lack of awareness can lead to costly repairs. Reports indicate that nearly 30% of car owners neglect to flush their cooling systems every two years. This oversight allows corrosion to build up, shortening the vehicle's lifespan. A proactive approach can mitigate this risk and ensure longer vehicle life.

Corrosion resistance in radiators is crucial for vehicle longevity. Effective materials can greatly enhance this resistance. According to a report by the International Journal of Corrosion, over 30% of radiator failures are due to corrosion. This reveals the urgent need for better materials.

One effective solution is the use of aluminum alloys. They provide improved resistance and are lightweight. Studies show that aluminum radiators can have a corrosion rate 50% lower than traditional materials. However, not all aluminum alloys perform equally. Some may corrode faster in certain environments, raising concerns.

Another innovative approach includes coatings. Epoxy and polymer coatings can create a barrier against corrosive agents. A recent analysis found that vehicles using these coatings lasted 15% longer in extreme conditions. Still, challenges remain. Some coatings can degrade over time, reducing effectiveness. Research is ongoing to optimize these solutions for all conditions, ensuring better protection for radiators.

Radiator maintenance is critical for vehicle longevity. Regular checks can help identify signs of corrosion early. Inspect hoses and connections for any leaks or wear. Small issues can turn into costly repairs.

Cooling systems require the right coolant mix. Use distilled water and recommended antifreeze ratios. This practice can prevent corrosion and clogging. Poor coolant quality may lead to overheating. Always replace old coolant according to the manufacturer’s guidelines.

Consider periodic professional inspections. A thorough check can spot rust, buildup, or damage invisible to the eye. Ignoring these aspects may compromise your radiator's efficiency. Just washing the exterior might give a false sense of security. Stay proactive to ensure a healthier radiator for the long haul.

The future of radiator technology is gearing towards enhanced durability. Innovations are reshaping how radiators resist corrosion. A recent study from the Automotive Research Institute highlights that nearly 30% of radiator failures are due to corrosion. This statistic underscores the need for robust solutions in vehicle maintenance.

One promising advancement is the development of protective coatings. These coatings can significantly extend the life of radiators. They act as a barrier against corrosive agents found in engine coolant. Research indicates that vehicles equipped with these coatings show a 40% increase in lifespan. While this sounds impressive, the complexity of application remains a challenge. It requires precise conditions to achieve optimal results.

Tip: Regularly inspect your radiator for leaks. Identifying issues early can prevent larger problems down the road. Additionally, consider using quality coolant solutions to protect your radiator's health. However, not all coolants are equal. Some may react negatively with certain materials. Always do thorough research before making a choice.

Future developments also focus on materials. For example, aluminum radiators are now blended with advanced alloys. This enhances strength without adding weight. However, not every manufacturer adopts these innovations. As demands grow, so will the pressure to keep up. It bears reflection on the industry's slow adaptation. The question remains: are we moving fast enough to meet future needs?